❏

3. Mix a small batch of 30-minute epoxy. Use a

thin, metal ruler or something similar to force epoxy

into the hinge slots in one of the flaps and in the

hinge slots in the matching half of the wing. Proceed

immediately to the next step.

❏

4. One at a time, lightly coat the top and bottom of

one half of four hinges with epoxy, then insert the

coated end of the hinges into the flap. Working

carefully not to get any epoxy into the hinge pins, use

small scraps of balsa or something similar to wipe off

excess epoxy as it is forced back out of the hinge

slots. Proceed immediately to the next step.

❏

5. Use a piece of wire or a toothpick to apply epoxy

in the hole and groove in the flap for the joiner wire.

Coat the matching half of the control horn with epoxy,

and then insert it into the flap. Coat the other side of

hinges protruding from the flap with epoxy, and then

join the flap to the wing with the joiner wire. Wipe

away excess epoxy as it squeezes out.

❏

6. Without using any glue, temporarily join the

other flap to the wing and the joiner wire. This will

align the joiner wire while the epoxy on the other side

is hardening. Do not disturb the wing until the epoxy

hardens.

❏

7. After the epoxy on the first flap has hardened,

glue the other flap to the wing the same way. Allow

the epoxy on both flaps to fully harden for at least a

few hours before moving them. After the epoxy has

hardened, “break” the flaps free by rapidly moving

them up and down several times. Use a hobby knife

to pick any bits of epoxy from the hinge pins.

❏

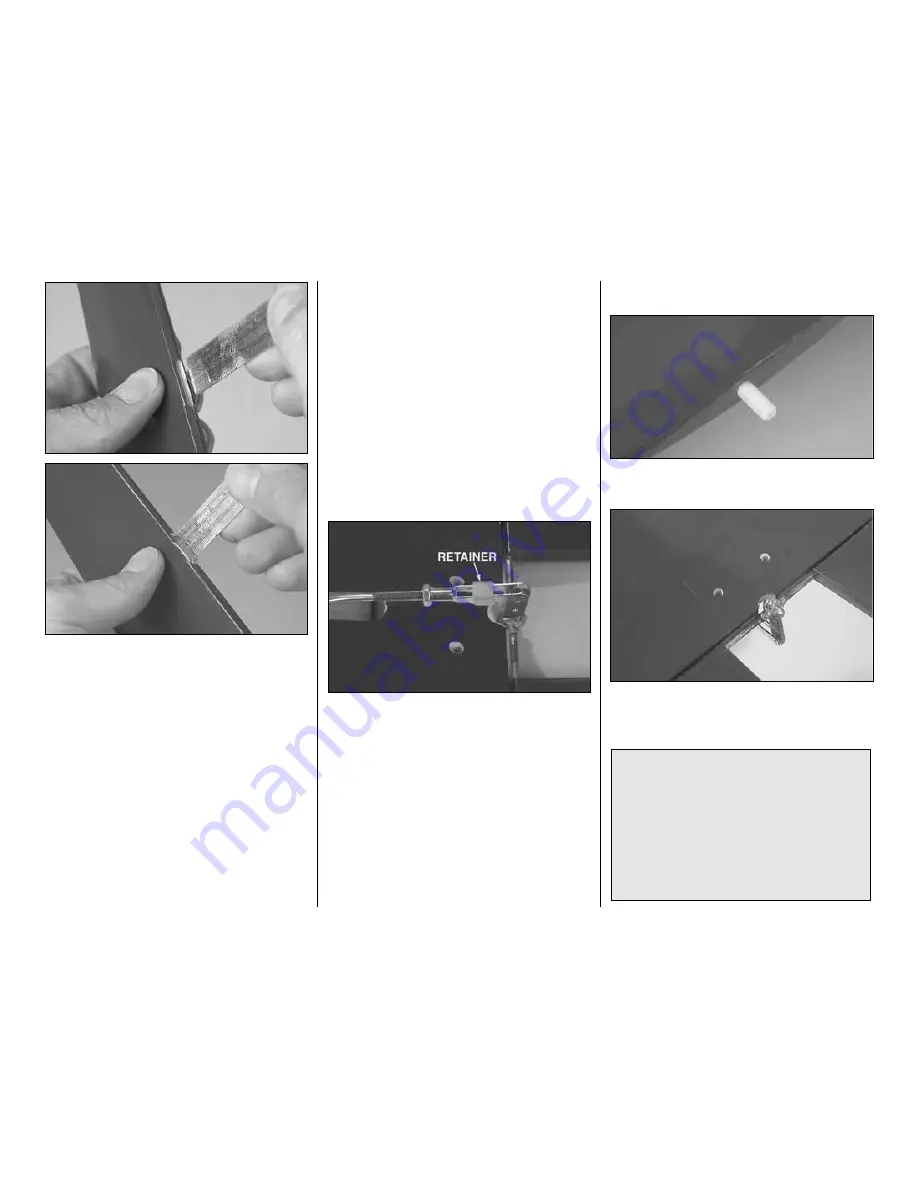

8. Adjust the clevis on the flap pushrod so the flaps

will be centered when the bellcrank is neutral. Slip a

silicone clevis retainer over the clevis, then connect

the clevis to the top hole in the control horn. Slip the

retainer over the clevis, and then tighten the 4-40 nut.

Finish the Wing

❏

1. Cut the covering from the hole in the front of the

wing and glue in the wing dowel.

❏

2. Cut the covering from the top and bottom of the

wing over the holes near the trailing edge for the

wing bolts.

Note: The Nobler includes bolts for mounting the

wing to the fuselage. However, the wing bolts are

intended for alignment and assembly only. Later,

the wing will be permanently glued to the

fuselage. If considering modifying your Nobler to

make the wing removable, keep in mind that

disengaging the elevator pushrod from the flap

control horn in order to remove the wing would

be cumbersome. Further, the Nobler has not

been flight tested with a removable wing.

- 9 -