❏

3. Test fit one of the metal clevises in the holes in

both control horns on both joiner wires. If the clevis

pins don’t go in, enlarge the holes in the joiner wires

with a 1/16" [1.6mm] drill. Clean the joiner wires with

denatured alcohol, and then thoroughly roughen them

with coarse sandpaper so epoxy will adhere.

❏

4. Temporarily connect the clevis on the flap

pushrod to the top hole in the control horn on one of

the joiner wires. Position the joiner wire so the

pushrod is centered in the exit slot in the wing. Then

mark the location of the joiner wire onto the flaps.

❏

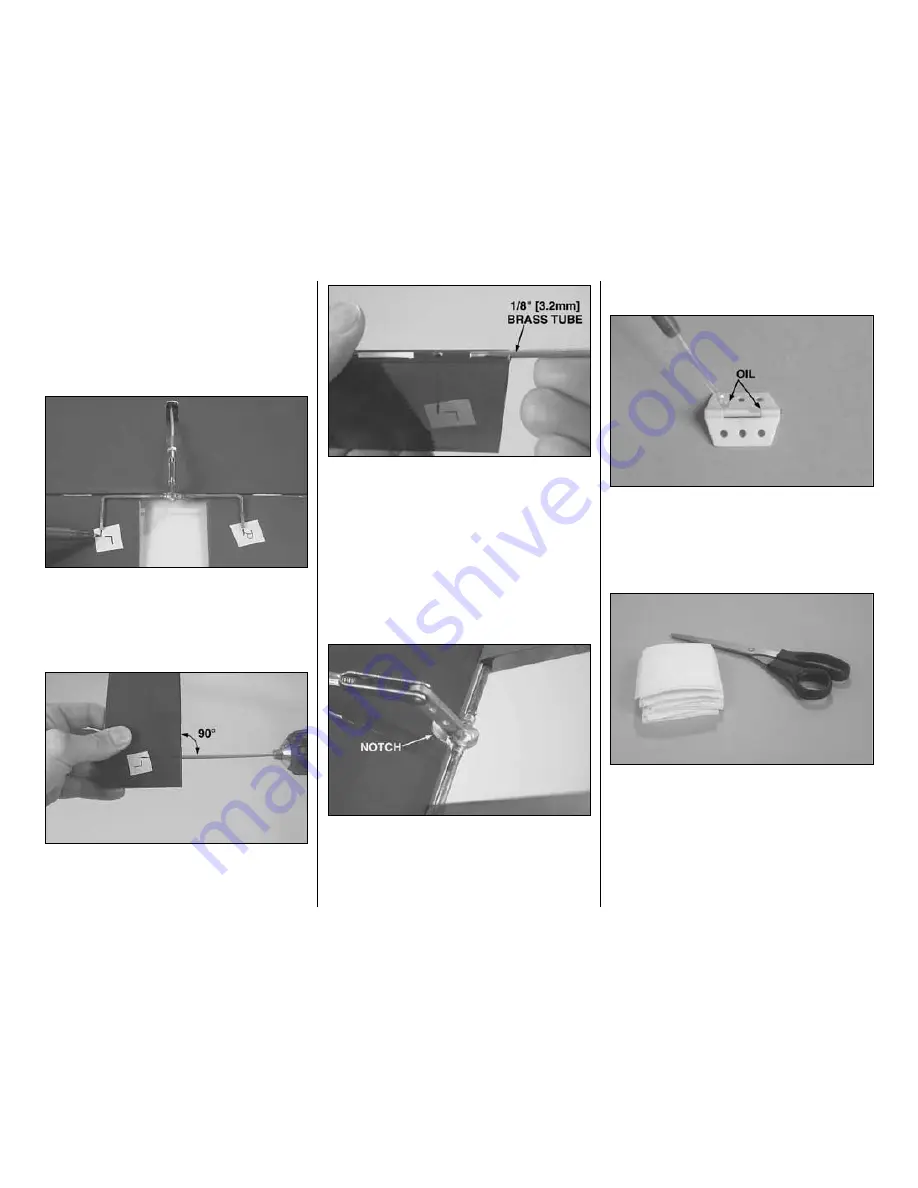

5. Use a 1/8" [3.2mm] brass tube sharpened on

the end or a 1/8" [3.2mm] drill to drill holes into the

flaps in alignment with the marks that note the

location of the joiner wire.

❏

6. Use a 1/8" [3.2mm] brass tube sharpened on

the end or a hobby knife to cut grooves in the leading

edge of the flaps to accommodate the wire.

❏

7. Test fit both flaps to the joiner wire. View the

trailing edges of the flaps from the end of the wing.

See if the flaps are parallel with each other (have the

same “up” and “down”). If necessary, “tweak” the

joiner wire to align the flaps.

❏

8. Test fit the flaps to the wing with the joiner wire.

Cut a half-round notch in the trailing edge of the wing

to accommodate the solder joint and the control horn

during maximum flap deflection. Make certain

nothing interferes with full, smooth flap movement.

Make adjustments where necessary.

Join the Flaps to the Wing

❏

1. Remove the flaps, hinges and joiner wire from

the wing. Carefully apply a small dab of petroleum

jelly or small drop of oil to the pivot points on the

hinges to keep epoxy from getting into the hinge joint

and jamming up the hinges.

❏

2. Lay two or three paper towels on top of each

other. Cut the stack into small squares by cutting the

stack into four, equal-width strips. Cut the strips into

four equal squares. These paper towel squares will

come in handy throughout the building project (and

save you from wasting whole paper towels!).

One flap at a time will be glued to the wing…

- 8 -