IMPORTANT BUILDING NOTES

• There are two types of screws used in this kit:

Sheet metal screws are designated by a number

and a length.

For example #6 x 3/4" long [19mm]

This is a number six screw that is 3/4" [19mm] long.

Machine screws are designated by a number,

threads per inch, and a length.

For example 4-40 x 3/4" long [19mm]

This is a number four screw that is 3/4" [19.1mm]

long with forty threads per inch.

• When you see the term test fit in the instructions,

it means that you should first position the part on

the assembly without using any glue, then

slightly modify or

custom fit the part as necessary

for the best fit.

• Whenever the term glue is written you should rely

upon your experience to decide what type of glue

to use. When a specific type of adhesive works

best for that step, the instructions will tell you what

glue is recommended.

• Whenever just epoxy is specified, you may use

either 30-minute (or 45-minute) epoxy or 6-minute

epoxy. When 30-minute epoxy is specified, it is

highly recommended that you use only 30-minute

(or 45-minute) epoxy because you will need the

working time and/or the additional strength.

• Photos and sketches are placed before the

step they refer to. Frequently you can study photos in

following steps to get another view of the same parts.

ASSEMBLE THE WING

Hinge the Flaps

❏

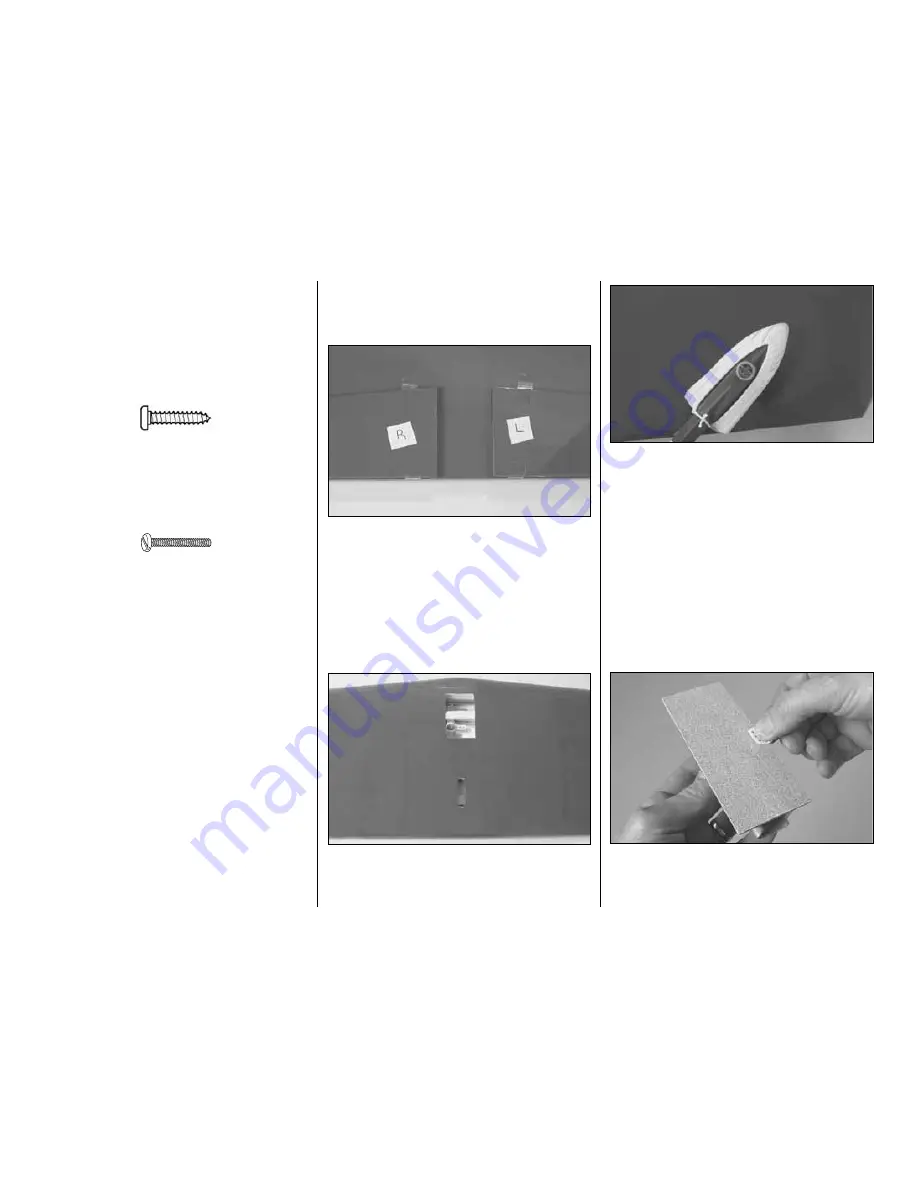

1. Mark the flaps as “right” and “left” before

removing them from the wing (the right flap is about

3/4" [20mm] shorter than the left flap).

❏

2. Separate the flaps from the wing by peeling off

the tape. Any glue left from the tape can be removed

with naphtha lighter fluid or denatured alcohol.

❏

3. Cut and remove the covering from the top of the

wing over the bellcrank opening and the pushrod

exit. Also cut the covering from the opening in the

bottom of the wing directly under the bellcrank screw.

❏

4. Use a covering iron with a covering sock to

remove any wrinkles in the covering on the wing and

flaps. The best way is to glide the iron over the

covering until the wrinkles disappear, and then go

over the area again pushing down to bond the

covering to the wood. If the wrinkles don’t go away,

the balsa in that area may be bending inward. If this

is happening, do not press down on the iron in that

area. Simply let the heat of the iron shrink the

covering. If the wrinkles momentarily disappear, then

immediately reappear, the iron may be too hot, thus

causing air bubbles. Lower the temperature of the

iron or use a sharp #11 blade to puncture several

holes in the covering, then reheat. The suggested

iron temperature is around 360 degrees F.

❏

5. Using a bar sander or a sanding block with

medium-grit sandpaper, remove any raised molding

imperfections and roughen the gluing surface of all

the hinges so glue will adhere.

- 6 -