172-65169MA-08 (MC-COS Multi-control Valve) 28 May 2010

30

Troubleshooting

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

When using this product, NEVER stand close to, or leave tools anywhere

near moving parts, such as the ajustment screw. Contact with moving

parts or objects becoming caught in moving parts could lead to injury or

damage or other accidents.

CAUTION

This product is shipped after stringent checks and inspection and should perform its

intended function for a long period of time without failure. However, should there be

any problem encountered in the operation of the MC-COS, identify where the

trouble occurs and consult the troubleshooting guide below. When a problem arises,

the trouble may lie in the MC-COS drive section, pressure reducing valve (including

separator/trap) or the controller.

Identifying Problem Areas

1. Set the operation mode to MANUAL (MAN) on the controller connected to the

MC-COS. This is to enable the operation signal to the drive section to be changed

to any value.

2. Set the control output on the controller to any value. Check to make sure that the

pressure adjustment screw in the drive section is stopped completely and is not

hunting (the secondary steam pressure is stabilized).

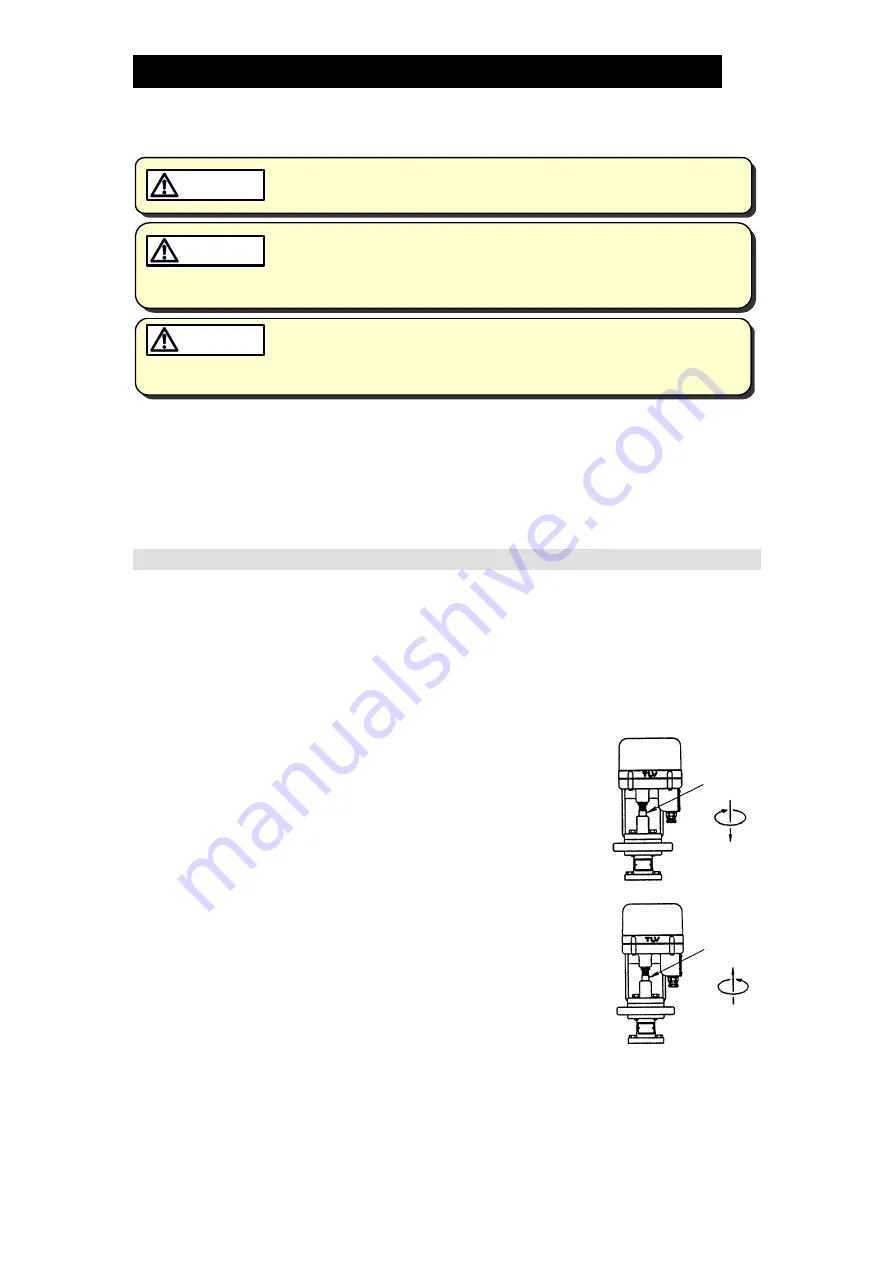

3. Increase the control output on the controller. Check to make

sure that, as viewed from above, the pressure adjustment

screw rotates clockwise while moving downward, and that

the secondary steam pressure increases.

4. In the same manner, decrease the control output on the

controller. Check to make sure that, as viewed from above,

the pressure adjustment screw rotates counterclockwise

while moving upward, and that the secondary steam

pressure decreases.

5. If the process in steps 2. – 4. above reveals that:

• The pressure adjustment screw is operating normally but the secondary steam

pressure does not change, then see the

Pressure Reducing Valve

Troubleshooting

section.

• The pressure adjustment screw does not rotate, then go on to the next step.

Adjustment

Screw

Clockwise &

Down

Adjustment

Screw

Counter-

clockwise

& Up