www.THORav.us | [email protected] | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

9

MECHANICAL

VIDEO SYSTEM

THOR LED Panels are available with Brompton and NovaStar processing. Contact THOR for specifics.

Pixel capacity per port may vary based on LED wall mapping configuration and pixel pitch.

PROCESSING

LED PANELS PER PROCESSOR PORT

RIDGE 1.8

RIDGE 2.5

RIDGE 3.7

60Hz 120Hz 180Hz 240Hz

60Hz 120Hz 180Hz 240Hz

60Hz 120Hz 180Hz 240Hz

8 bit

Panel Qty

9

4

3

2

16

8

5

4

36

18

12

9

10 bit

Panel Qty

7

3

2

1

12

6

4

3

29

14

9

7

12 bit

Panel Qty

6

3

2

1

10

5

3

2

24

12

8

6

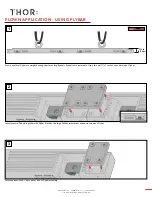

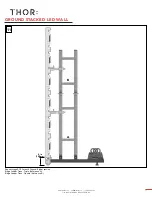

Structural integrity for all types of LED wall installation applications (Flown and Ground Stack) is required

for each site and verified by a structural engineer.

See Important Safety Considerations on page 10.

STRUCTURAL

ELECTRICAL

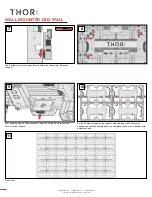

Ground Stack LED walls require ballasting a percentage of the total weight. Ballast the LED wall by

distributing evenly on the Rear Ground Bars.

Ballast Weight Calculator

Wall Height, 1-3 meters — 50% of wall weight

Wall Height, 4 meters — 75% of wall weight

Wall Height, 5 meters — 100% of wall weight

Wall Height, 6 meters — 100%* of wall weight

If a wall weighs 3,300lbs., then the total ballasting weight is 1650lbs. If there are 12 Rear Ground Bars for

this LED wall, 137.5lbs. is needed for each Rear Ground Bar.

*At 6 meters we recommend adding another row of Rear Ground Bar and another set of Rear Ground

Truss.

Verify the mounting structure load capacity (truss, purlins, schedule 80 pipe, unistrut, etc). Determine

adequate amount of pick points for stabilizing LED wall.

BALLASTING

RIGGING

EDGE Panels require 110-240 VAC, 50-60 Hz and should be 16A or less. Proper grounding is required.

POWER