MAINTENANCE

3Ć23

1186 MM267 (6–94)

4. To adjust belt tension, loosen the belt

adjusting stud nut. Pull the vacuum fan

assembly back to tighten the belt and tighten

the stud nut.

A

C

B

06320

VACUUM FAN

A. Vacuum Fan

B. Adjustment Slot

C. Stud Nut

5. Recheck belt tension.

6. Close the filter cover.

TO REPLACE VACUUM FAN BELT

1. Stop the engine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

2. Open the filter cover.

3. Loosen the vacuum fan belt.

4. Slide the belt off the sheaves.

5. Position the new belt on the engine sheave

and the vacuum fan sheave.

6. Adjust belt tension as described in TO

CHECK AND ADJUST VACUUM FAN BELT

TENSION.

7. Close the filter cover.

WHEEL DRIVE CHAINS

The two wheel drive chains transfer power from

the differential to the drive wheels. Lubricate the

chains with a penetrating-type spray lubricant

after every 100 hours of operation.

Check the chains for wear or damage and tension

after the first 50 hours of operation and then after

every 100 hours of operation. The wheel drive

chains should have 0.5 in (15 mm) slack

measured midway between the sprockets.

C

D

B

A

03139

WHEEL DRIVE CHAIN

A. Adjustment Bolts

B. Sprocket

C. Chain

D. Adjustment Block

STATIC DRAG CHAIN

A static drag chain is provided to prevent the

buildup of static electricity in the machine. The

chain is attached to the machine by a rear brush

skirt mounting bolt.

Check the chain for wear periodically. Make sure

it is making contact with the floor at all times.

Содержание 1186

Страница 1: ...1186 MM267 Rev 05 12 95 Operator Manual ...

Страница 8: ...GENERAL INFORMATION 1186 MM267 6 94 vi ...

Страница 10: ...SPECIFICATIONS 1186 MM267 6 94 1Ć2 ...

Страница 14: ...OPERATION 1186 MM267 6 94 2Ć2 ...

Страница 32: ...MAINTENANCE 1186 MM267 6 94 3Ć2 ...

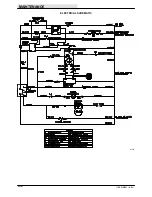

Страница 46: ...MAINTENANCE 1186 MM267 6 94 3Ć16 ELECTRICAL SCHEMATIC 06779 ...

Страница 68: ...APPENDIX 1186 MM267 6 94 4Ć2 ...

Страница 70: ...APPENDIX 1186 MM267 6 94 4Ć4 ...