*

After completing the first 450 hours of operation, repeat the

service schedule given in the above chart.

*

Usually the service is carried out in every 100 hours. For

new tractor, however, 1st service should be carried out the

time of 50 hours of run.

DAILY

INSPECTION

1.

Check for leakage of oil, water or fuel. Check hydraulic

hoses, fuel pipes, tank, filters and connections, shaft hitch

points and oil plugs, if you observe or detect any leakage

on parts, visit your dealer.

2.

Check the engine oil, transmission oil, coolant and water. If

the level is not proper, replenish.

3.

After finishing work, replenish with fuel up to within 1 in. (25

mm) below the fuel tank filler cap.

4.

After

working in dusty places,

clean the air cleaner.

Remove dried grass etc. from the radiator front and clean

the radiator and radiator screen.

5.

Tightening nuts and bolts

Tighten the front and rear wheel fixing bolts.

All other nuts and bolts should be firmly tightened.

6.

After working in a muddy place, grease the king pin front

axle center pin and brake shaft via the grease nipples pro-

vided.

7.

Check the tire pressure and set if required. If it is not as

specified inflate the tube to specific pressure.

8.

Check the brake and clutch pedals for correct free play. If it

is

not as specified make necessary adjustment.

9.

All moving portions must be cleaned and lubricate with

engine oil so that they work smoothly.

10.

For conventional batteries: Check the electrolyte level in

the battery, and if it’s below the specified level add distilled

water.

11.

Check the fan belt tension and if it is slack, adjust it.

1. SERVICE

(50 hours of operation)

NOTE

1.

A

new tractor needs good attention. Following should be

read carefully to understand all things to be done.

2.

Some items described here are the same as daily inspection

but special care should be given to them when carrying out

the 50 hours service.

50-HOURS 1st SERVICE FOR

A

NEW TRACTOR

1.

Replace engine filter and engine oil.

2.

Replace transmission oil.

3.

Retighten all bolts and nuts, paying special attention to

those for steering linkage and wheel.

4.

Check and adjust the fan belt tension.

5.

Check the wheels to see if their condition is good and tire

pressure is correct.

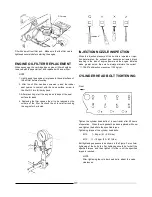

6.

Retighten the cylinder head bolts and adjust valve clear-

ances.

7.

Front axle diff. case and gear case oil replacement of 4-

wheel drive tractor.

8.

Replace coolant.

9.

Clean the air cleaner.

10.

Clean the fuel filter.

11.

Check the front hub for end-play.

12.

For conventional batteries: Check the battery electrolyte for

its level and specific gravity.

13.

Clean the hydraulic oil filter.

50-HOUR SERVICE FOR OTHER THAN NEW TRACTOR

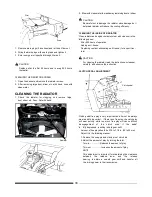

1.

Cleaning the air cleaner element

Blow compressed air to inside of an element and clean it

thoroughly. If the element is remarkably dirty, wash it with

a

neutral detergent. Wipe off or blow off with air the dust on

the

dust pan and body.

2.

Clutch adjustment

Adjust the clutch pedal so that there Is correct amount of

free play.

3.

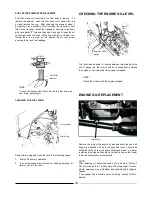

Cooling water replenishment

Check that the specified quantity of cooling water is

entered and if not, upto the marked level, fill with water up

to within 1 in. below the filler cap.

The full amount of cool-

ing water cannot be supplied in one operation. When cool-

ing water has been completely drained, fill with new water,

then run the engine at low revolution for a short period and

then fill to the specified level again. Check the water hose

for damage and inspect connections for leaks.

23

Содержание VST 818

Страница 2: ......

Страница 16: ...SECTION 2 EXTERNAL VIEW AND NOMENCLATURE OF EACH PART The above photos show TARAL VST 818 6 ...

Страница 35: ...25 ...

Страница 36: ...GREASING DIAGRAM Greasing Nipple Greasing Nipple Greasing Nipple 26 ...

Страница 45: ...PROPER BATTERY MAINTENANCE AND TIPS FOR SAFETY 35 ...

Страница 53: ...SECTION 8 WIRING DIAGRAM 43 ...

Страница 58: ......

Страница 59: ......