7.

MAINTENANCE

Tapflo LPX series

26

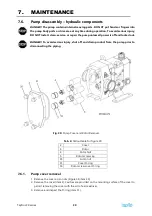

Gear Oil Specification

ISO Grade 320, SAE 140 or AGMA Number 6EP

Tab. 2:

Gear oil volume

Model

Gear oil volume

Horizontal ports

Vertical ports

25-1, 25-2, 40-1, 40-2, 50-1

100 ml

170 ml

50-2, 80-1

325 ml

490 ml

100-1

625 ml

1125 ml

7.2.3.

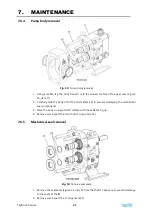

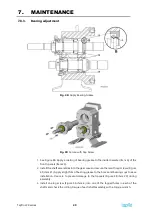

Bearing lubrication

Bearings are factory-lubricated with grease. Table 3 provides approximate volumes for

adequate re-greasing. Grease the bearings every 250 hours.

Excess grease will accumulate in the gear case. Remove it through the cleanout hole covered

with a plastic plug (Figure 26, item D).

Bearing Lubricant Grease

NLGI Grade No. 2, EP, Lithium-based lubricant

Tab. 3:

Grease quantity

Model

Gear oil volume

Front bearing

Rear bearing

25-1, 25-2, 40-1, 40-2, 50-1

5 ml

4 ml

50-2, 80-1

10 ml

9 ml

100-1

17 ml

14 ml

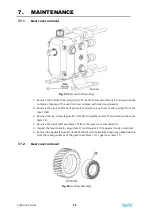

7.3.

Maintenance inspections

DANGER!

The pump contains internal moving parts. DO NOT put hands or fingers into

the pump body ports or drive area at any time during operation. To avoid serious injury,

DO NOT install, clean, service, or repair the pump unless all power is off and locked out.

Fig. 27:

Check for wear

Detecting wear in the early stages can reduce repair costs and down time. A simple “look-

feel” inspection of the pump during breakdown cleaning is recommended to detect signs of

trouble at an early stage.

Содержание LPX Series

Страница 57: ...9 PARTS LISTS Tapflo LPX series 57 9 PARTS LISTS 9 1 Model 25 1 to 50 1 Pump Parts A exploded view ...

Страница 59: ...9 PARTS LISTS Tapflo LPX series 59 9 3 Model 25 1 to 50 1 Pump Parts B exploded view ...

Страница 61: ...9 PARTS LISTS Tapflo LPX series 61 9 5 Model 50 2 to 100 1 Pump Parts A exploded view ...

Страница 63: ...9 PARTS LISTS Tapflo LPX series 63 9 7 Model 50 2 to 100 1 Pump Parts B exploded view ...

Страница 69: ...Tapflo LPX series 69 ...