66

We reserve the right to make changes without any prior notice.

Translation from original instructions

-

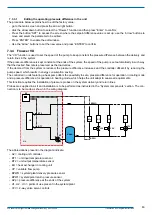

Vmin = minimum water volume in the system/plant

- UL = limit of the supply.

7.3.5.1

Setting the operating setpoint difference

Below is the procedure to be followed to edit the pressure difference setpoint.

- go to the main screen and press the arrow right button;

-

click the arrow down button to select the “Flowzer” function and then press “Enter” to confirm;

-

Press the button “SET” to access the screen where the setpoint difference value is set up: use the “arrow” buttons to

move and select the parameter to be edited.

-

Press “ENTER” to enable the edit window.

-

Use the “arrow” buttons to set the new value and press “ENTER” to confirm.

7.3.5.2

Instructions for system start-up

In addition to the instructions provided in the section on unit “Commissioning”, a check is required in systems featuring the

“VFPP” function for correct sizing of the pumps in order to ensure proper setting and increased efficiency under low load

conditions.

Correct sizing is obtained with checking of pump operation at the rated flow rate of the system/plant and at the minimum

flow rate.

For these checks, it is not necessary for there to be a load demand because these are checks of the hydraulic system.

7.3.5.3

Checking the rated flow rate

Open all the system/plant user points present and wait for about ten minutes until the system reaches an equilibrium.

The following situations can occur:

1.

The ΔPp value reaches the required setpoint within the set differential; the ΔPex value is within the value range set in

parameters “PA22” and “PA55”; the pump works at a percentage higher than 80%; the system can be considered well

calibrated at its nominal operating point. But, if in this condition, the pump has to work at below 80%, the pump is oversi-

zed for the specific system/plant and should therefore be re-selected, otherwise its control margin would be excessively

reduced with consequent reduction in efficiency of the variable flow rate system.

2.

The ΔPp value reaches the required setpoint within the set differential, but the ΔPex value is higher than the value sto

-

red in parameter “PA55”. This means that the water flow rate calculated by the system is higher than the required rated

flow, as a result of which the ΔPp setpoint must be reduced until the ΔPex parameter falls within the value range set in

parameters “PA22” and “PA55”. In this new condition, the pump must work at a percentage higher than 80%, in which

case the check can be considered successfully finished. But, if in this condition, the pump has to work at below 80%, the

pump is oversized for the specific system/plant and should therefore be re-selected, otherwise its control margin would

be excessively reduced with consequent reduction in efficiency of the variable flow rate system.

3.

The ΔPp value reaches the required setpoint within the set differential, but the ΔPex value is lower than the value stored

in parameter “PA22”. This means the water flow rate calculated by the system is lower than the required rated flow, as a

result of which the ΔPp setpoint must be increased until the ΔPex parameter falls within the value range set in parame

-

ters “PA22” and “PA55”. In this new condition, the pump must work at a percentage higher than 80%, in which case the

check can be considered successfully finished. But, if in this condition, the pump has to work at below 80%, the pump

is oversized for the specific system/plant and should therefore be re-selected, otherwise its control margin would be

excessively reduced with consequent reduction in efficiency of the variable flow rate system.

4.

The ΔPp value fails to reach the required setpoint. The pump will operate at 100% (the controller increases the pump

speed to reach the setpoint value stored in parameter ΔPp). In this case, the value of the ΔPp setpoint must be reduced

in order for the pump speed to exceed 80% and for the value stored in ΔPex to be correct, ranging between the values

set in parameters “PA22” and “PA55”.If possible, you can calibrate/partially close the user points and then repeat the

test.

5.

The ΔPp value fails to reach the required setpoint. As in the previous case, the pump will necessarily operate at 100%,

but the value in ΔPex is smaller than the value in parameter “PA22”. This means the pump is insufficient to overcome

the total head losses of the system, and therefore, if there are no margins for improvement (partially closed valves/gate

valves, clogged filters, etc.), the pump must be replaced with one having a higher head.