61

We reserve the right to make changes without any prior notice.

Translation from original instructions

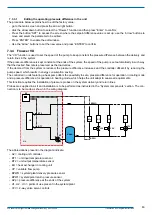

The abbreviations present in the diagram indicate:

- A2 = cooling unit controller

- BT1 = unit input temperature sensor

- BT2 = unit output temperature sensor

- EU = heat exchanger in cooling unit

-

BP41= differential pressure sensor;

-

ΔPex = pressure difference at the ends of the unit;

-

VPP = variable flow pump in primary circuit;

-

VPS = variable flow pump in secondary circuit;

-

U1, U2 .. Un = points of use present in the system/plant

- Y2V = 2-way valve servo controls

- Y3V = 3-way valve servo controls

-

Vmin = minimum water volume in the system/plant

- UL = limit of the supply.

User points in the system provided with 3-way valves help reduce the capacity of the buffer tank.

To this purpose, the 3-way valves should be fitted on the furthest user points.

The bypass pipe must be of the same diameter as the connections of the unit.

7.3.2.5

Setting the operating setpoint difference

The units are shipped from the factory with a setpoint difference value of 5°C.

The procedure below explains how to edit the factory value.

- go to the main screen and press the arrow right button;

-

click the arrow down button to select the “Flowzer” function and then press “Enter” to confirm;

-

Press the “SET” button and access the screen where the setpoint difference value is set up.

-

Press “ENTER” to enable the edit window.

-

Use the “arrow” buttons to set the new value and press “ENTER” to confirm.

Check that the flow rate through the heat exchanger in the unit, including without thermal load, is within the

operating limits admitted in the technical catalogue.