Содержание Lift Jockey LJS2000

Страница 2: ......

Страница 13: ...13 TECHNICAL DATA Hardware...

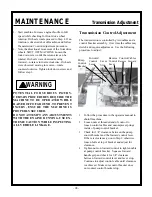

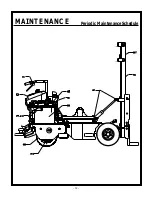

Страница 34: ...34 MAINTENANCE Periodic Maintenance Schedule...

Страница 35: ...35 MAINTENANCE Periodic Maintenance Schedule...

Страница 38: ......

Страница 40: ...40 PARTS LIST Tilt Cylinder Front Cowl Assembly...

Страница 41: ...41 PARTS LIST Tilt Cylinder Front Cowl Assembly...

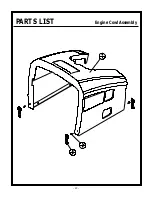

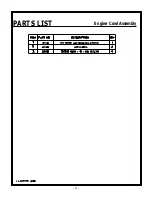

Страница 42: ...42 PARTS LIST Engine Cowl Assembly...

Страница 43: ...43 PARTS LIST Engine Cowl Assembly...

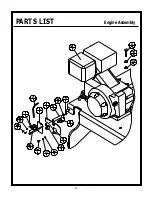

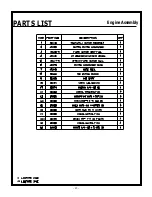

Страница 44: ...44 PARTS LIST Engine Assembly...

Страница 45: ...45 PARTS LIST Engine Assembly...

Страница 46: ...46 PARTS LIST Pump Assembly...

Страница 47: ...47 PARTS LIST Pump Assembly...

Страница 48: ...48 PARTS LIST Battery Hose Clamp Assembly...

Страница 49: ...49 PARTS LIST Battery Hose Clamp Assembly...

Страница 50: ...50 PARTS LIST Steering Housing Assembly...

Страница 51: ...51 PARTS LIST Steering Housing Assembly...

Страница 52: ...52 PARTS LIST Hydraulic Tank Assembly...

Страница 53: ...53 PARTS LIST Hydraulic Tank Assembly...

Страница 54: ...54 PARTS LIST Steering Handle Bar Fuel Tank Assembly...

Страница 55: ...55 PARTS LIST Steering Handle Bar Fuel Tank Assembly...

Страница 56: ...56 PARTS LIST Platform Brake Pedal Assembly...

Страница 57: ...57 PARTS LIST Platform Brake Pedal Assembly...

Страница 58: ...58 PARTS LIST Brake Linkage Assembly...

Страница 59: ...59 PARTS LIST Brake Linkage Assembly...

Страница 60: ...60 PARTS LIST Wheelmotor Brake Tire Assembly...

Страница 61: ...61 PARTS LIST Wheelmotor Brake Tire Assembly...

Страница 62: ...62 PARTS LIST Quick Change Hub Assembly...

Страница 63: ...63 PARTS LIST Quick Change Hub Assembly...

Страница 64: ...64 PARTS LIST Hand Foot Mast Control Assembly...

Страница 65: ...65 PARTS LIST Hand Foot Mast Control Assembly...

Страница 66: ...66 PARTS LIST Mast Assembly...

Страница 67: ...67 PARTS LIST Mast Assembly...

Страница 68: ...68 PARTS LIST Mast Assembly...

Страница 69: ...69 PARTS LIST Mast Assembly...

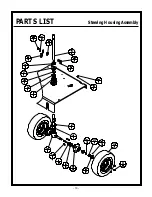

Страница 70: ...70 PARTS LIST Lift Frame Assembly...

Страница 71: ...71 PARTS LIST Lift Frame Assembly...

Страница 72: ...72 PARTS LIST Hydraulic Piping Schematic...

Страница 73: ...73 PARTS LIST Hydraulic Piping Schematic...

Страница 74: ...74 PARTS LIST Hydraulic Piping Schematic...

Страница 75: ...75 PARTS LIST Hydraulic Piping Schematic...

Страница 76: ...76 PARTS LIST Hydraulic System Schematic...

Страница 77: ...77 PARTS LIST Hydraulic System Schematic...

Страница 78: ...78 PARTS LIST Electrical Wiring Schematic...

Страница 79: ...79 PARTS LIST Electrical Wiring Schematic...

Страница 80: ...80 PARTS LIST 55398 Decal Identification...

Страница 82: ...82 PARTS LIST Decal Identification...

Страница 84: ......

Страница 85: ......

Страница 86: ......