39

WARNING

Hazardous voltage

Make sure the machine is off when disassembling

for servicing. The machine must be disconnected

from electrical supply before removing any access

panel. Failure to disconnect power before servicing

could result in death or serious injury.

6.7

SPIGOT SWITCH

The spigot switch is a normally closed, held open switch.

When a spigot is pulled, the spigot switch sends a signal

to the IntelliTec2 control to start the auger drive and

refrigeration system. This signal moves the control to

“Serve Mode”, or if it already is in “Serve Mode”, it resets the

cycle count. After serving product, the IntelliTec continues

a freezing cycle until the product reaches consistency.

SPIGOT SWITCH TEST - ADJUSTMENT

NOTE

Adjustments to the spigot switch should be done

after the product is at consistency in “Serve Mode”

or when the machine is empty.

1.

Open the spigot slowly and listen for a click when

the spigot switch closes.

2.

The clicking sound should be within the first 1/2” of

the spigot glide movement (Refer to Figure 6-5). If

the switch does not close, an adjustment may be

necessary.

NOTE

The center spigot has two switches; one for each

side. When testing the center spigot, there should

be two audible clicks occurring almost simulta-

neously.

SPIGOT SWITCH TESTING - ELECTRICAL

1.

Disconnect the switch from the circuit by unplugging

the connectors.

2.

Check resistance readings across the common

(COM) and normally closed (NC) terminals. When

the spigot is closed, the resistance should show

an open. When the spigot is opened, the switch will

close and the resistance should be 0 ohms.

SPIGOT SWITCH ADJUSTMENT

1.

Turn the machine off by pressing the Main Power

On/Off button.

2.

Remove the header panel.

3.

Loosen the bolts on the spigot switch.

4.

Using a pencil, mark the spigot glide 1/4” from the

spigot housing.

5.

Adjust the switch to activate when the plastic glide

reaches the mark.

6.

Fully tighten the retaining bolts and remove mark

from spigot glide.

SPIGOT SWITCH REPLACEMENT

1.

Remove the header panel.

2.

Remove the dispense rate adjuster knob located

below the header panel. (Refer to Figure 6-6)

3.

Remove the two Phillips head screws that attach

the spigot cam assembly to the panel. Remove the

assembly.

4.

Disconnect the connector from the switch and

remove the switch..

5.

Install the replacement switch onto the handle

assembly. Do not fully tighten the retaining screws

at this time.

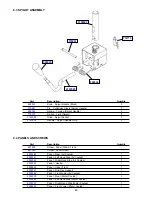

Figure 6-7 Spigot Switch Replacement

Spigot Glide

COM

NC

Figure 6-6 Spigot Cam Assembly (Center Spigot)

Содержание O231

Страница 1: ...Model O231 SERVICE MANUAL Manual No 513646 Sept 2010 ...

Страница 2: ......

Страница 10: ...4 ...

Страница 12: ...6 ...

Страница 20: ...14 ...

Страница 30: ...24 ...

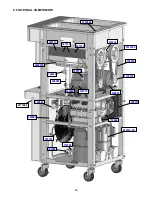

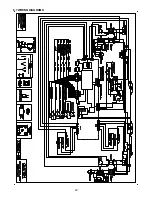

Страница 58: ...52 8 7 WIRING DIAGRAMS ...

Страница 59: ...53 ...

Страница 60: ...54 ...

Страница 61: ...55 ...

Страница 62: ...56 ...