36

9.

After the test, stop the motor by exiting the Testing

and Manual Operation section. Turn the machine

off and disconnect from the electrical supply.

10.

Install the belt and tighten the tension bolt.

11.

Use a Burroughs Belt Tension Gauge to set the

tension for the drive belt. Set the belt tension to 40

lbs.

12.

Using a straightedge, align the drive motor pulley

with the gearbox pulley. Tighten the two allen head

screws.

B. DRIVE MOTOR REMOVAL

1.

Disconnect machine from electrical supply before

removing any panels for servicing.

2.

Remove the back panel and the side panel.

3.

Remove the electrical cover plate from the back of

the motor.

4.

Identify (mark) wires and remove them from the

motor.

5.

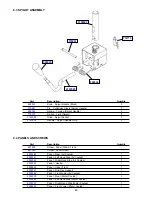

Loosen the belt tension adjustment bolt and remove

the belt. (Refer to Figure 6-3)

7.

Remove the motor mounting bolts.

8.

Loosen the two allen head screws from the pulley.

9.

Remove the pulley and key from the motor shaft.

2.

Check to ensure contactor is receiving signal.

Read voltage across the coils of the contactor

during a freezing cycle. Voltage should be about

230V. If there is no voltage reading, refer to Section

7 Troubleshooting.

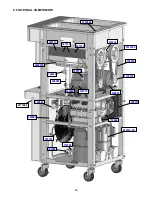

6.3

DRIVE MOTOR

The O231 has two drive motors. They are used to rotate the

auger assemblies. An internal, normally closed, centrifugal

switch starts the drive motor. The motors have an internal

thermal overload.

A. DRIVE MOTOR TEST

1.

Turn the machine off by pressing the Main Power

Off/On button and disconnect the machine from

the electrical supply.

2.

Remove the back panel and a side panel.

3.

Loosen the belt tension adjustment nut and remove

the belt.

4.

Connect power to the machine.

5.

Turn the machine on by pressing the Main Power

Off/On button.

6.

Press the right arrow, SET, then the SEL button to

access the technician level on the control.

7.

Activate the drive motor through the Left Output

Control or Right Output Control menus which are

located under Utilities in the Testing and Manual

Operation screen. Refer to Section 4 for details.

8.

Go to the Test Monitoring screen under Utilities.

The motor current should be as follows:

Single Phase Machines: 6.1-6.3 Amps

Three Phase Machines: 4.0-4.2 Amps

NOTE

The motor amps are based on 230VAC supply volt-

age.

WARNING

Hazardous voltage

Make sure the machine is off when disassembling

for servicing. The machine must be disconnected

from electrical supply before removing any access

panel. Failure to disconnect power before servicing

could result in death or serious injury.

Figure 6-3 Motor Mounting

Tension

Adjustment

Bolt

Содержание O231

Страница 1: ...Model O231 SERVICE MANUAL Manual No 513646 Sept 2010 ...

Страница 2: ......

Страница 10: ...4 ...

Страница 12: ...6 ...

Страница 20: ...14 ...

Страница 30: ...24 ...

Страница 58: ...52 8 7 WIRING DIAGRAMS ...

Страница 59: ...53 ...

Страница 60: ...54 ...

Страница 61: ...55 ...

Страница 62: ...56 ...