37

C. DRIVE MOTOR INSTALLATION

1.

Place the drive motor in position and install the four

mounting bolts.

2.

Place the pulley and key on the motor shaft.

NOTE

Do not tighten the pulley screws until after the belt

tension has been properly adjusted.

3.

Install the belt and tighten the tension adjustment

bolt.

4.

Use a Burroughs Belt Tension Gauge to set the

tension for the drive belt. Set the belt tension to 40

lbs.

5.

Using a straightedge, align the drive motor pulley

with the gearbox pulley. Tighten the two allen head

screws.

6.

Install wiring according to wiring diagram (located

behind the left side panel). Install electrical cover

plate on the motor.

7.

Install back and side panels.

6.4

CAPACITORS

The compressor start and run capacitors are only on single

phase machines. They are accessible by removing the right

side panel.

The start and run capacitors for the drive motors are

mounted directly onto each motor body.

A. CAPACITOR TEST

1.

Disconnect machine from electrical supply before

removing any panels for servicing.

2.

Remove a lead from one of the capacitor terminals.

3.

Using insulated pliers, discharge the capacitor by

connecting a 20K

Ω

5W resistor across the

terminals.

NOTE

Discharge the capacitor even if there is a bleeder

resistor across the terminals. There may be an open

in the bleeder resistor preventing it from working

properly.

4.

Disconnect the bleeder resistor from the circuit.

5.

Measure the capacitance across the terminals.

The results should be as follows:

B. CAPACITOR REPLACEMENT

1.

Disconnect machine from electrical supply before

removing any panels for servicing.

2.

Remove leads from the capacitor terminals.

3.

Using insulated pliers, discharge the capacitor

with a 20K

Ω

5W resistor across the terminals.

NOTE

Discharge the capacitor even if there is a bleeder

resistor across the terminals. There may be an open

in the bleeder resistor preventing it from working

properly.

4.

Pull the capacitor out of its holder and replace.

5.

Connect the leads to the terminals of the new

capacitor.

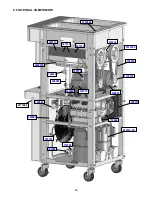

6.5

GEARBOX

A. GEARBOX INSPECTION

Inspect the gearbox and listen for unusual noise. A grinding

sound generally indicates a bad gear.

B. GEARBOX REMOVAL

1.

Disconnect machine from electrical supply before

removing any panels for servicing.

2.

Remove the back panel and the side panel.

3.

Remove the belts.

4.

Remove the bolts holding the gearbox assembly

and remove it.

C. GEARBOX INSTALLATION

1.

Place the gearbox in position from the rear of the

machine. Fasten the bolts through the gearbox to

the rear of the barrel.

2.

Mount the pulley on the gearbox shaft and align

with the motor pulley, then tighten the allen head

screws.

3.

Install the belt.

4.

Use a Burroughs Belt Tension Gauge to set the

tension for the drive belt. Set the belt tension to 40

lbs.

5.

Using a straightedge, align the drive motor pulley

with the gearbox pulley. Tighten the two allen head

screws.

WARNING

Hazardous voltage

Make sure the machine is off when disassembling

for servicing. The machine must be disconnected

from electrical supply before removing any access

panel. Failure to disconnect power before servicing

could result in death or serious injury.

Part

MFD

VAC

Drive Motor Start

230622

200 MFD

250 VAC

Drive Motor Run

231075

30 MFD

370 VAC

Compressor Start

231058

145-174 MFD

250 VAC

Compressor Run

231057

35 MFD

370 VAC

Rating

Содержание O231

Страница 1: ...Model O231 SERVICE MANUAL Manual No 513646 Sept 2010 ...

Страница 2: ......

Страница 10: ...4 ...

Страница 12: ...6 ...

Страница 20: ...14 ...

Страница 30: ...24 ...

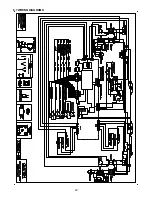

Страница 58: ...52 8 7 WIRING DIAGRAMS ...

Страница 59: ...53 ...

Страница 60: ...54 ...

Страница 61: ...55 ...

Страница 62: ...56 ...