5-25

4. MECHANISM CHECKS AND

ADJUSTMENTS

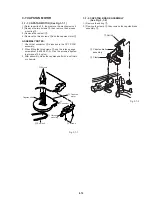

4-1. REEL TABLE TORQUE CHECK

1) With the power switch turned OFF, stick black vinyl tape

over the photo diodes of the tape sensors. Then turn

the power switch ON. Front loading will begin. Refer to

section 3-2 and Fig. 3-2-2. and release the locks of the

tray lock lever and the lid opener lever.

NOTES:

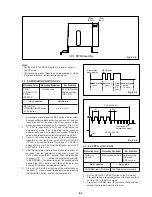

1. The measurements must be taken without any incan-

descent light or daylight.

2. If the mechanism cannot be put into PLAY, FF or REW

mode by the method described in 1) above, make a

dummy cassette tape, as shown in Fig. 4-1-2. The dummy

cassette tape is made as follows: Unscrew the five screws

on the underside, remove the reels, leaf springs and other

parts on the supply and take up sides, make holes in the

upper surface as wide as the reel diameter, then assemble

the parts.

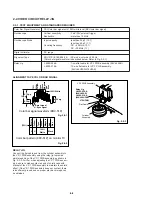

2) Put the mechanism into REW mode, wait at least 10 sec-

onds, then measure the torque value of the reel table on

the supply side. It should be at least 600 g/cm. Take the

measurement with the torque dial gauge (H-7099-039-H/

H-7099-035-H) held in position in your hand (lock torque).

While taking the measurement, rotate the reel table (take

up reel assembly) on the take up side with your hand so

that the reel sensor does not respond.

3) After switching to FF mode, wait for at least 10 seconds

and then measure the torque value of the reel table on

the take up side. It should be at least 600g/cm (lock

torque).

4) After switching to PLAY mode, wait for at least 10

seconds and then measure the torque value of the reel

table on the take up side. It should be between 80 and

140g/cm (lock torque).

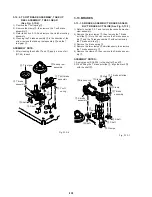

Torque dial gauge

(H-7099-039-H)

(H-7099-035-H)

Reel table on

supply side

Reel table on

take up side

Fig. 4-1-1

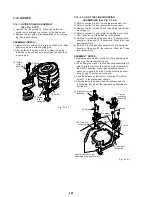

Stick black vinyl

tape over the tape

sensor holes.

Dummy cassette

tape

Make holes with

roughly the same

diameter as the reel.

Fig. 4-1-2

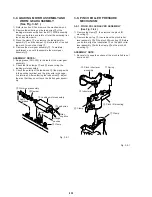

4-2. ADJUSTING THE BT LEVER ASSEM-

BLY POSITION AND CHECKING THE

BACK TENSION TORQUE IN PLAY

MODE

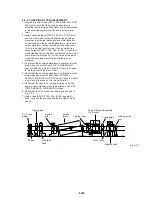

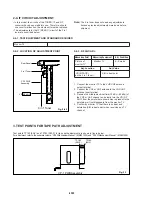

4-2-1. BT LEVER POLE POSITION ADJUSTMENT

(See Fig. 4-2-1 )

1) Without loading a cassette tape, put the mechanism into

PLAY mode (turn the power switch OFF).

2) Adjust point

A

on the band brake assembly by rotating

it so that the tip of the BT lever assembly is aligned with

the line on the left side of the mechanism chassis.

3) Refer to section 4-2-2 and check that the back tension

torque is between 30 and 50g/cm.

Align the end of the BT lever

assembly with this line.

BT lever assembly

Tension

pole

Point

A

Fig. 4-2-1

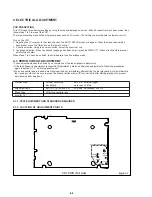

4-2-2. CHECKING THE BACK TENSION TORQUE

PLAY MODE

1) Mount the cassette torque meter (VHT-063S) and

switch to PLAY mode.

2) Check that the back tension torque is between 30 and

50g/cm .

Содержание SLV-L45AR

Страница 6: ...1 2 ...

Страница 7: ...1 3 ...

Страница 8: ...1 4 ...

Страница 9: ...1 5 ...

Страница 10: ...1 6 ...

Страница 11: ...1 7 ...

Страница 12: ...1 8 E ...

Страница 17: ...3 2 MECHANISM CONNECTION DIAGRAM ...

Страница 18: ...3 3 3 4 SLV L45AR L65HFAR L75HFAR OVERALL WIRING DIAGRAM SLV L45AR ...

Страница 19: ...SLV L45AR L65HFAR L75HFAR OVERALL WIRING DIAGRAM SLV L65HFAR L75HFAR 3 5 3 6 ...

Страница 20: ...3 7 3 8 SLV L45AR L65HFAR L75HFAR SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L45AR ...

Страница 21: ...3 9 3 10 SLV L45AR L65HFAR L75HFAR SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L65HFAR L75HFAR ...

Страница 22: ...3 11 3 12 SLV L45AR L65HFAR L75HFAR VIDEO CIRCUIT DIAGRAM SLV L45AR AUDIO CIRCUIT DIAGRAM SLV L45AR ...

Страница 25: ...SLV L45AR L65HFAR L75HFAR 4 3 4 4 CP 1 BOARD VA A VIDEO AUDIO TUNER CIRCUIT DIAGRAM SLV L45AR ...

Страница 26: ...SLV L45AR L65HFAR L75HFAR 4 5 4 6 CP 1 BOARD VA A VIDEO AUDIO TUNER CIRCUIT DIAGRAM SLV L65HFAR L75HFAR ...

Страница 27: ...SLV L45AR L65HFAR L75HFAR 4 7 4 8 VIDEO CIRCUIT WAVEFORMS VP 1 BOARD VIDEO PRE AMP CIRCUIT DIAGRAM SLV L45AR ...

Страница 32: ...SLV L45AR L65HFAR L75HFAR 4 17 4 18 CP 1 BOARD SY A SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L45AR ...

Страница 33: ...4 19 4 20 CP 1 BOARD SY A SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L65HFAR L75HFAR ...