18

Solarbayer GmbH

MOUNTING INSTRUCTION

High capcity collector PremiumPlan

Filling with heat transfer fluid

Flush

The solar system has to be flushed

with the ready mixed heat transfer

fluid

Course of action:

- check if all screwed connections

are tightened

- check the primary pressure of the

solar expansion vessel at zero

pressure, if necessary adjust to

2,5 bar

- switch the solar station’s ball val-

ves of flow and return to 45° - that

will open the gravity brakes

- close hex key of flow regulator

- connect the hoses of the filling

station with the corresponding

valves

- open any other valve (if existing)

- adjust the inversion valve (if exis-

ting) to “manual”; convert the exits

one after the other during the

flushing

- the solar system can now be flus-

hed in both directions; keep an

eye on the manometer

-

don’t

flush/fill the solar system

when it is under direct exposure

to light

- the flushing has been successful

when the fluid returns clean and

without air bubbles into the con-

tainer

- operating pressure has to be at

least 3 bar

- close the filling and draining val-

ves and completely open the flow

regulator

- open the ball valves and put the

switching valves (if existing)

- the solar system is now ready for

operation

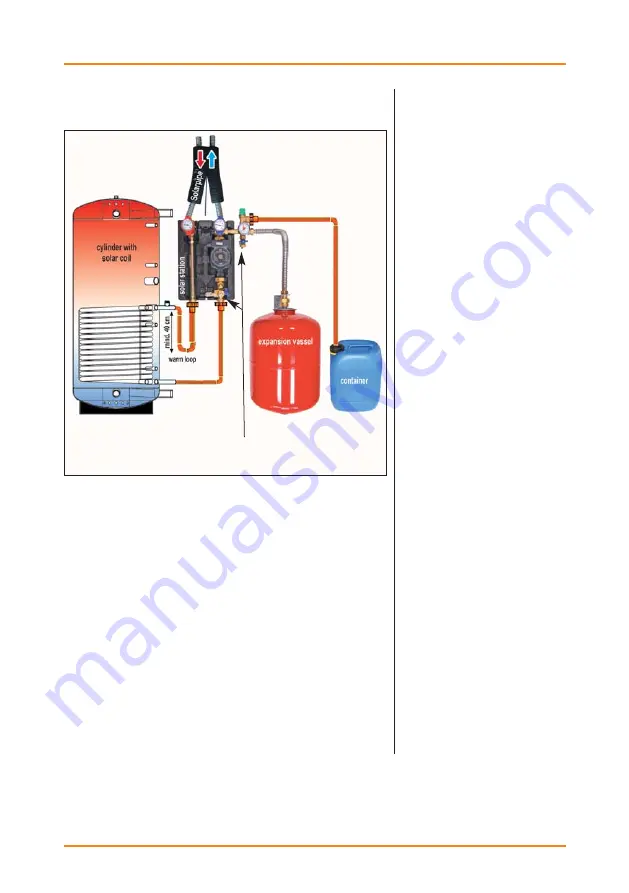

filling

and

draining

valve

connect the filling station here to fill

and flush the system

Due to their construction the collectors can afterwards never be fully emptied again(vapours and

freezing might lead to damages). It is therefore necessary to rinse the collectors with a glycol

mixture. Our collectors are only to be used with Tyfocor L/LS

Mixing of the heat transfer fluid

You have a protection against frost up to a -24°C when mixing ratio

is 60/40 (60 parts water and 40 parts propylene glycol). A further

decrease of temperature leads to a formation of ice without any ex-

plosive effect. In locations with a risk of frost under -30°C a mixing

ratio of 50/50 is recommended.

You definitely have to mix the fluid in a separate container be-

fore filling the system

CAUTION: The collectors have to be filled with heat-transfer

fluid even if the outdoor temperature is over the freezing

point.

Characteristic data of Tyfocor L

boiling point: 187°C

pour point: <-60°C

flaming point: ~368°C

pH (conc.).: 7,7-8,7 (1:1 – H

²

O/glykol)