18

10.2

Brake caliper. Checking, maintenance

Before setting up the caliper, loosen the brake cable as much as

possible as specified in

10.1 on page 17.

To adjust the brake caliper, remove the cover using a cross

screwdriver�

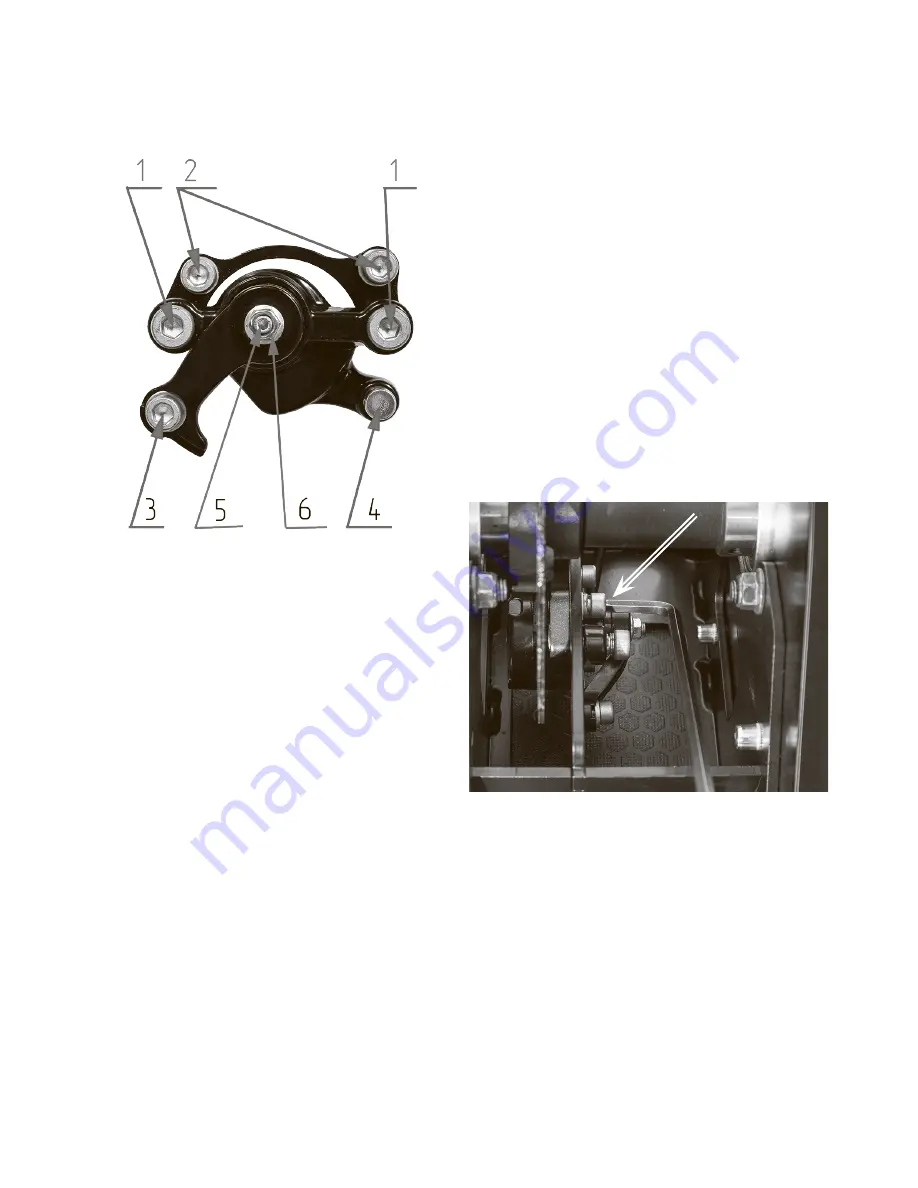

Caliper parts

1�

Bolts to adjust the position of the caliper (parallelism

of the brake pads in respect of the brake disc)

2�

Bolts of fastening the caliper

3�

Bolt of fastening the brake cable

4�

Stop of the tube guide cable of the brake

5�

Bolt to adjust the distance between the pads

6�

Lock nut of the adjusting bolt

10.2.1

Adjusting the brake caliper

Fully loosen the tension of the brake cable on the lever, as

described in�

10.1 on page 17.

Ensure ease of pushing and return to the starting position of the

lever and the parking brake cable.

At the complicated movement of the parking brake lever, lubricate

or replace the cable.

If the parking brake lever is in the initial position, and the cable

slacks, adjust the tension of the cable on the parking brake

caliper. Loosen the bolt 3 and pull the cable to remove slacking.

Do not create tension of the cable.

Tighten the bolt and check the operation of the parking brake

lever�

By rotating the bolts 1, adjust the position of the caliper relative

to the brake disc. The fixed brake pad should be parallel to the

brake disc plane. Adjust the minimal possible distance between

the fixed brake pads and the brake disc. Allowed is the brake

pad’s touching the disc, if its rotation is not obstructed.

Loosen the lock nut 5. Tighten the screw 6 until the movable

brake pad’s touching the brake disc. When holding the bolt 6

tighten the locknut 5. Check the brake disk rotation. Allowed is

the brake pads’ touching the disc, if its rotation is not obstructed.

Check the free travel of the parking brake lever. If necessary,

adjust the tension of the cable as described in.

10.1 on page

17

10.2.2 Removal and installation of the brake caliper

By using the INBUS allen wrench or another hex slot, unscrew

the bolts 2.