10

Section 2 - OPERATING INSTRUCTIONS

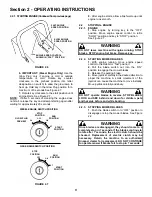

IMPORTANT: This Out Front Z-Rider is equipped with

hydrostatic drive. The forward and rearward movement

of the machine is controlled by a joystick lever.

Joystick operations should be performed only from the

operator’s position in the seat. A small movement of

the joystick can cause the machine to move instantly.

Move joystick very carefully and slowly.

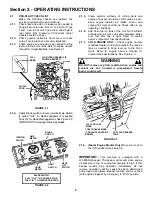

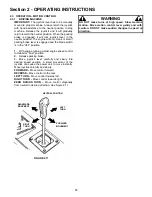

ROLL RELEASE: To roll the machine without the

engine running, pressure within the hydraulic pumps

must be released. There is one lever on the upper

right side of each pump that is used to release the

pressure. Rotate lever counter clockwise and secure

in that position . See Figure 2.4.

FIGURE 2.4

2.2

STARTING & STOPPING - ENGINE, BLADES &

PARKING BRAKE

This machine is equipped with dual

hydrostatic wheel drive transmissions. Each

transmission is controlled by a single motion

control lever or joystick. This single control

lever (joystick) controls the direction of

motion, Forward and Reverse, and the speed

of motion. Move the joystick forward to propel

the machine forward. Move the control

rearward to propel the machine in reverse.

The speed of motion is continuously variable

from neutral (zero) to maximum.

Moving the joystick farther from the neutral

position will cause the speed of motion to

increase. To turn, move the joystick towards

the side you want to turn to.

DO NOT make sudden changes in speed or

direction. Always slow machine motion before

turning. To stop the motion of the machine

bring the joystick back to the neutral position.

Engage parking brake.

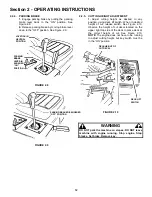

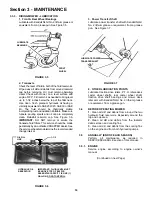

2.2.1. STARTING

ENGINE

When the ignition key is turned to “START”, the

engine will not turn over unless the parking

brake is engaged and the blade switch is in the

“OFF” position!

Be seated on the Out Front Z-Rider before

attempting to start the engine with the key

switch.

1. Complete pre-start checklist.

2. Sit in operator’s seat.

3. Push blade switch in to “OFF”, blades

disengaged position and engage parking brake.

See Figure 2.2.

FIGURE 2.5

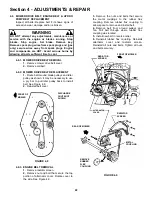

4. Move engine speed control to a medium

speed position. See Figure 2.6.

5.

IMPORTANT: (Gasoline Engine Only).

Move engine choke control to the choke position

to start a cold engine. After starting choke

control must be moved to "OFF" no choke

position.

PRESSURE

RELEASE LEVER

LEVER IS IN POSITION FOR

PROPELLING RIDER UNDER

IT’S OWN POWER (RIDER

WILL NOT ROLL WITH LEVER

IN THIS POSITION)

LEVER IS ROTATED COUNTER

CLOCKWISE AND LATCHED IN A

SECURED POSITION FOR ROLLING

RIDER (RIDER WILL NOT PROPEL

ITSELF WITH LEVER IN THIS

POSITION)

PRESSURE

RELEASE LEVER

PARKING

BRAKE

ENGAGED

DISENGAGED

Содержание EZF2100DKU, EZF2300GKU, EZF520

Страница 30: ...30 NOTES...

Страница 31: ...31 NOTES...