4. Installation instructions

page 28

EN

4.6 Lubrication line connection

The main lubricant line connecting the compact

unit with the oil + air metering unit is already

installed on oil + air lubrication systems.

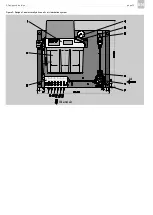

Install the lubrication point line(s) as shown in

Figure 5.

The lubrication point line leading from the oil + air

metering unit to the lubrication point must be

connected to the oil + air lubrication system in such

a way that no forces can be transferred to the

assembled oil + air lubrication system (stress-free

connection).

Lubrication point lines made of transparent plastic

are recommended so that the lubricant transport

in the lubrication point lines (oil streak formation)

can be assessed visually. The requirements for the

lubrication point lines are summarized in Table 4.

Table 4: Requirements for lubrication point

lines

Lubrication point lines made of transparent plastic

are available in rigid (unplasticized) and flexible

(plasticized) designs with the following order num-

bers (please indicate requested length):

Rigid plastic tubing:

WVN715-RO4X0.85

Flexible plastic tubing:

WVN716-RO4X0.85

The connection for the lubrication point line is

designed as an M8x1 pipe thread with a counter-

bore for a solderless pipe union per

DIN 3854/DIN 3862 for pipe Ø 4 mm. The follow-

ing fittings are required to install the lubrication

point line:

Lubrication point line, plastic tubing Ø 4 mm:

404-603 Reinforcing socket

404-611 Tapered sleeve

404-612 Socket union

The lubrication point lines can be laid in a rising or

falling position. A hose coil (30) is installed approx.

0.3 m in front of the nozzle (32) and serves as a

lubricant reservoir. After the compressed air is

switched off, the lubricant distributed in the hose

coil collects in the lower bends of the coil. This

ensures that the bearing is quickly supplied with

lubricant once the compressed air is switched on

again. The center line of the hose coil should be

laid horizontally or inclined at a max. angle of 30°.

Avoid changes in the cross-section of the lubrica-

tion point line from small to large cross-sections in

the direction of flow. When the cross-section does

change, the transition should be gradual.

SKF oil-streak sensors are recommended for

monitoring a continuous lubricant flow in the

lubrication point lines. Oil-streak sensors allow

monitoring of the transport of the oil streak along

the wall of the lubrication line between the oil + air

metering unit or the mixing valve and the lubrica-

tion point.

Order number for oil-streak sensor:

GS4011-S20 for lubrication point line

Ø 4 mm

GS6011-S20 for lubrication point line

Ø 6 mm

Requirement

Values

Minimum length to hose coil

1 m

Maximum length to hose coil

10 m

Recommended lubrication

point line

- WVN715-RO4X0.85

- WVN716- RO4X0.85

Ø 4 x 0.85 mm

(wall thickness)

Содержание OLA Series

Страница 19: ...3 Design and function page 19 EN Figure 4 Hydraulic diagram of oil air lubrication system ...

Страница 37: ...6 Operation page 37 EN Oil air Exhaust air Figure 7 Lubricant delivery on various types of ball bearings ...

Страница 49: ...blank page ...

Страница 50: ...blank page ...

Страница 51: ...blank page ...