SIJECT OP15B Screens

SIJECT 16i Operation Manual

3-35

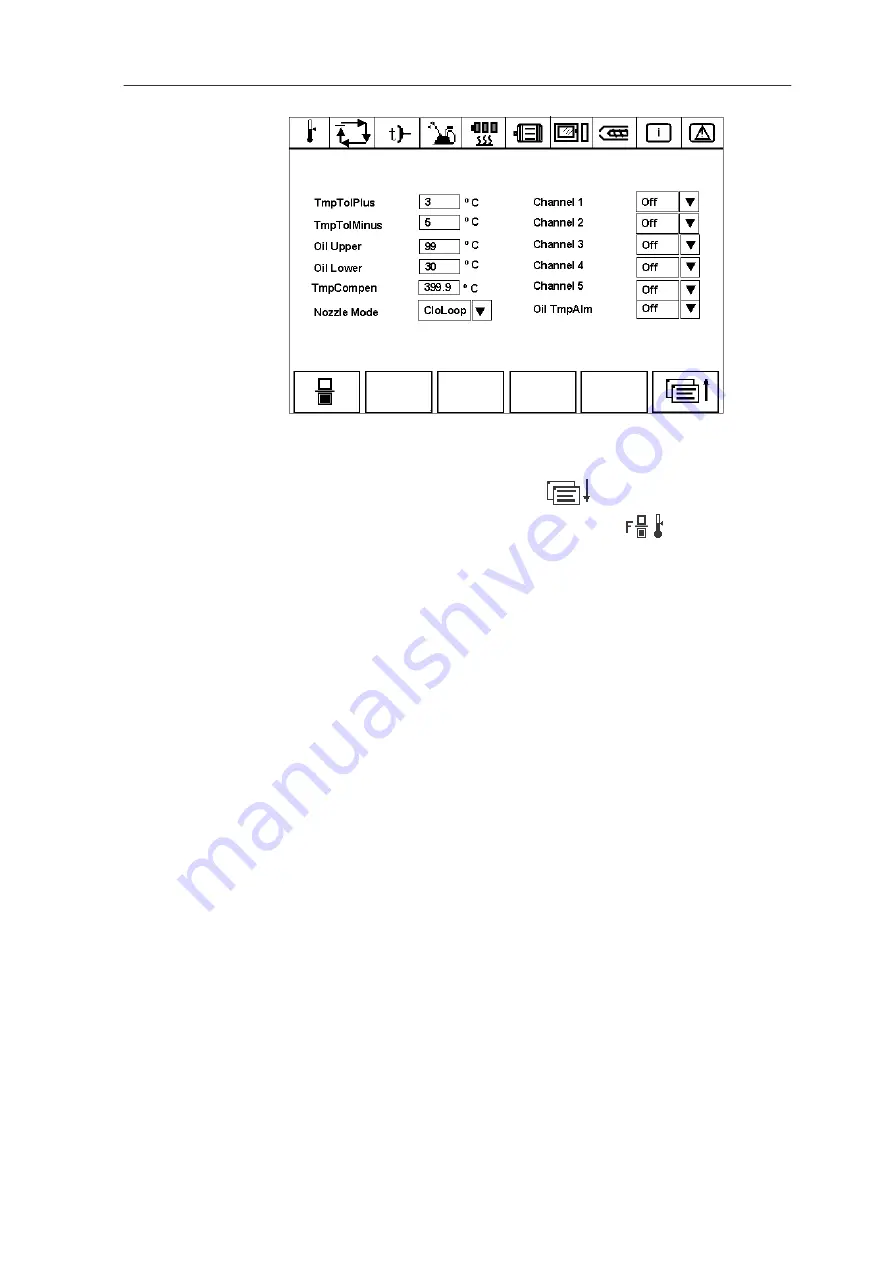

Fig 3-32

Service screen 2.3 – temperature setting

Temperature setting

On service screen 1, press softkey F2

to enter service screen 2 ---

linear scale setting. Then, press softkey F4

so as to enter

temperature setting screen. Temperature channel can be set from 1 to 5,

and temperature can be set accordingly.

Temperature Tolerance Plus --- set the tolerance plus for each

temperature channel.

Temperature Tolerance Minus --- set the tolerance minus for each

temperature channel.

Oil Upper --- set the upper limit of hydraulic oil temperature.

Oil Lower --- set the lower limit of hydraulic oil temperature.

Temperature Compensation --- set the temperature compensation. The

system has been set the compensation before delivery, and it is

unnecessary for users to set it again.

Nozzle Mode --- two modes are available, it can be assigned as close-loop

or open-loop.

Channel 1 --- select or deselect

Channel 2 --- select or deselect

Channel 3 --- select or deselect

Channel 4 --- select or deselect

Channel 5 --- select or deselect

Oil Temperature Alarm --- If oil temperature alarm is selected: when the

upper/lower limit of oil temperature has been set, there is no alarm if oil

temperature is within the specification and alarm occurs if it is out of

specification.

Содержание SIJECT 16i

Страница 1: ...User Manual User Documentation Software Version 1 11 2003 Edition SIJECT 16i Operation Manual ...

Страница 6: ......

Страница 26: ......