4

1 Introduction

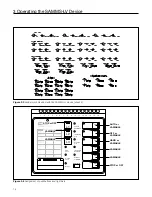

1 2 3

4 5 6 7 8 9 10 11 12 13

14 15 16

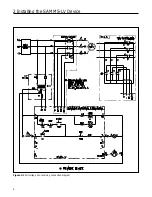

Figure 1.1

SAMMS-LV, front view

1.2.1 The SAMMS-LV Device Models

The SAMMS-LV device is available in two models: SAMMS-LVE

and SAMMS-LVX. Each model meets the various demands of

industrial and commercial specifications and installations. Table

1.2 compares the features of each model.

The SAMMS-LV device is designed for critical process control

where prevention of downtime is critical. It offers motor control

and protection along with motor diagnostic and motor/driven

equipment protection. Engineering and operating personnel

have access to important data enabling them to optimize

motor-driven equipment capabilities, maximize the process

system output and facilitate maintenance.

SAMMS-LVX is a full function model, applicable to all control

needs, from a simple across-the-line unit to a more compli-

cated reduced voltage scheme. It includes all of the functions

listed in table 3.7. Any of the standard control circuits listed in

table 3.3, or a custom circuit, may be downloaded. The

SAMMS-LVX device accepts up to four remote inputs, while

SAMMS-LVE accepts two remote inputs.

SAMMS-LVE is a model of SAMMS-LV tailored to across-the-

line (FVNR) applications. It provides all of the protective func-

tions of the SAMMS-LVX device, except that it has no jam

protection (F23), loss of load protection/alarm (F24), or process

current warning (F22) functions. Functions F3 and F5 associ-

ated with two-speed applications are not available. No provi-

sion for automatic reset (F8) is provided. SAMMS-LVE accepts

two remote inputs, and provides one output to actuate a single

contactor. An alarm contact is not available with SAMMS-LVE.

The SAMMS remote inputs are compatible with all PLCs and

electromechanical remote control devices that have a 120VAC

or 125VDC output signal.

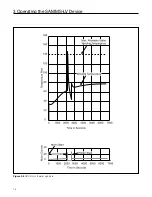

1.2.2 Advanced Protection for

Low-Voltage Motors

For advanced protection of low voltage motors, the SAMMS-LV

device uses a motor model algorithm that continually calculates

the stator winding and housing temperature as a function of the

motor rms current. The motor model compares the calculated

temperature to trip temperature values and provides a signal

that trips the motor off line when the motor reaches a trip

temperature value. The model closely emulates the heating and

cooling of the motor windings and provides protection against

both transient and steady-state overload conditions.