SR882 operation manual

~ 7 ~

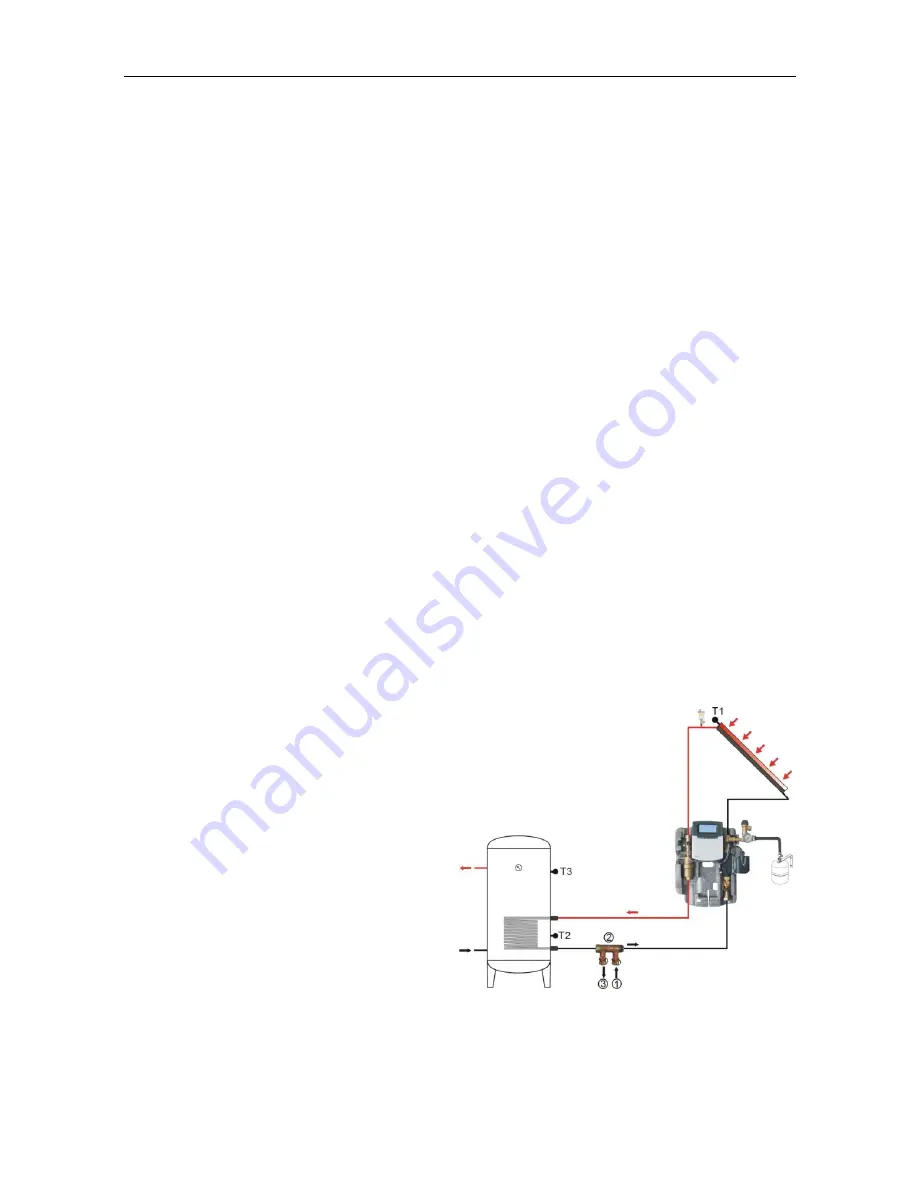

Connect the station to the solar thermal system.

Check the inlet pressure of the expansion vessel and if necessary, adjust it to the local

conditions, P

inlet

(bar) = 1bar+∆ Th(m)*1/10

(

∆Th=height difference between collector

and station

)

.

Connect the electrical components of the solar station, mount the store and collector

sensor and connect them to the controller, plug the controller into the socket.

Tighten all union nuts and screw connections. And mount the front half of the insulation

to the station.

3. Commissioning of station

Attention: Risk of scalding!

In order to prevent the boiling of solar fluid in the collectors, the system should not be

flushed or filled during periods of strong sunshine.

Attention: Risk of frost!

Solar thermal system cannot be completely emptied after flushing. There is a danger of

frost damage if water is used for flushing. Only use solar fluid to flush and fill the solar

thermal system. Use water

– propylene glycol mixture as solar fluid (Maximum 50%

propylene glycol).

3.1 Flushing and filling the solar system

Flushing and filling unit is the optional

component, it can be installed horizontally

at the lowest point of the solar circuit (see

figure). A filter must be installed between

the store and solar pump in order to

prevent the flushed-out scale from store

re-entering the solar circuit.

Flushing and filling steps:

Disconnect the expansion vessel from

the solar thermal system.

Connect the pressure hose of a flushing and filling station to the fill ball valve (1) of

flushing and filling unit.

Connect the flushing hose of a flushing and filling station to the drain ball valve (3) of