Sicma S.p.A.

Miglianico (CH)

page 27

When a tool (cutter/hammer) has to be replaced, it is advisable to replace the whole set. The use of

non-original tools might cause irregular vibrations on the machine.

If replacing operations are carried out with the machine lifted up, do not rely only on the hydraulic

lifter of the machine: it is recommended to place mechanic props or trestle supports between the

machine and the soil, thus preventing the head from suddenly and dangerously falling down.

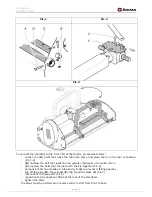

DRIVE BELTS REPLACEMENT

To replace the belts proceed as

follows (picture 11):

-

Remove roller

C

by

unfastening its tensioning

spring, unscrewing nut

B

with

a 32 mm key and holding pin

A

with a 22 mm key

-

Remove the damaged belt(s)

-

Position the new belt(s)

-

Proceed in reversed order to

reassemble the tensioning

roller, by properly adjusting

the tension of the belts (see

chapter “Adjustment of belts

tensioner”, page 22)

Picture 11

If a belt gets damaged, it is recommended to replace the whole set, in order to have the drive

tension equally balanced on each belt.

The pulleys are made integral to the transmission shaft by means of locking assemblies.

The torque to be applied to clamping screws is 17 Nm.

Содержание TB-110

Страница 2: ...Sicma S p A Miglianico CH page 2...

Страница 3: ...Sicma S p A Miglianico CH page 3...

Страница 30: ...Sicma S p A Miglianico CH page 30...

Страница 31: ...Sicma S p A Miglianico CH page 31...