Sicma S.p.A.

Miglianico (CH)

page 28

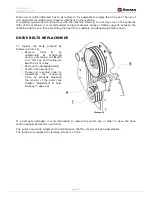

REPLACEMENT OF OLEODYNAMIC PIPES

When replacing pipes, make sure to operate in compliance with the safety measures to be taken for

maintenance interventions. After closing the valves of the hydraulic system, make sure to have no

pressure inside the pipes and unscrew the connections of the damaged pipe, bewaring of possible oil

leaks. Replace the damaged pipe with an original spare part, also checking the wear condition of the

connecting parts. Tighten carefully the pipe’s connections, in order to prevent the threads from

getting damaged, then check the pipes and make sure they are assembled tight.

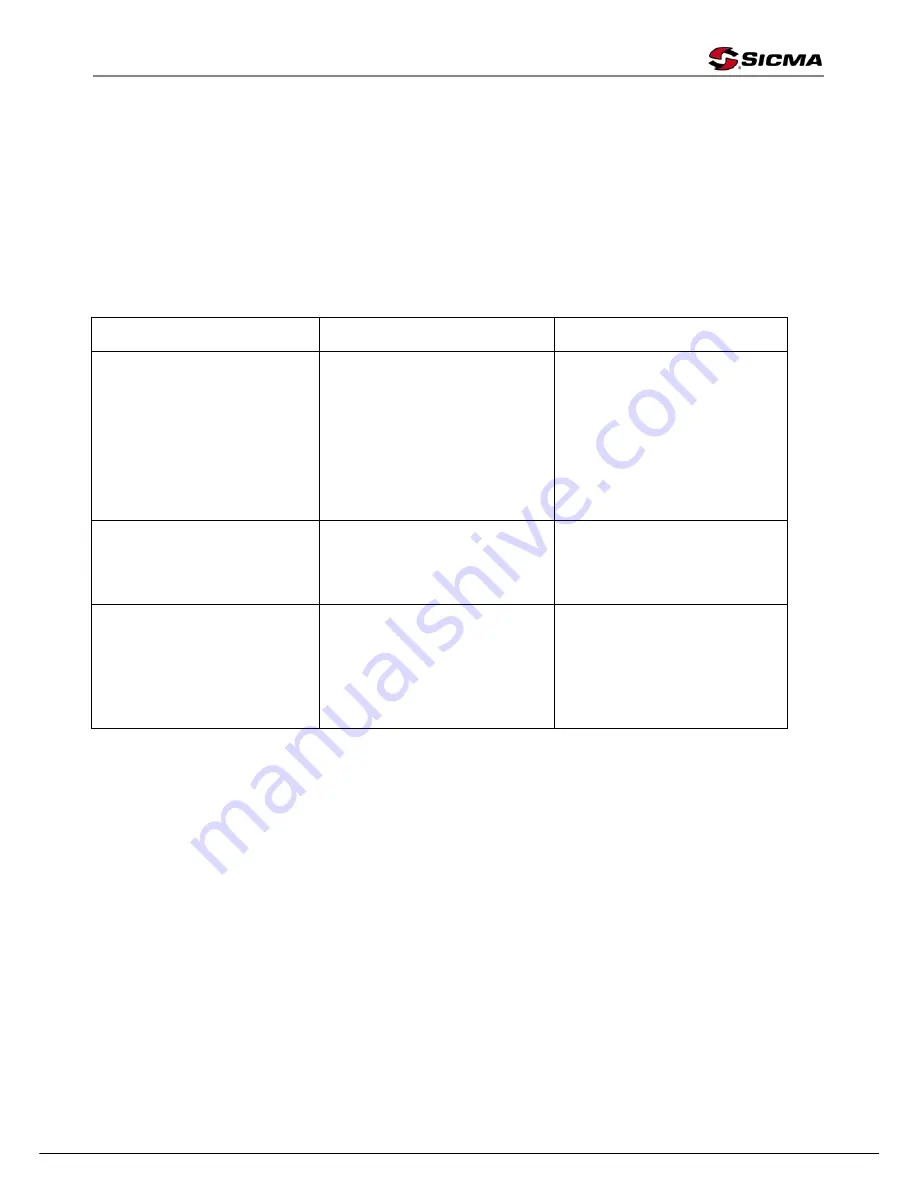

FAILURES CHART

MALFUNCTION CAUSE

SOLUTION

Material irregularly shredded

•

Cutters worn or damaged

•

Machine not properly

adjusted (skids or roller not

well in line)

•

Machine filled with

shredded material

•

Replace the cutters

•

Adjust skids and roller

•

Lower the advancing

speed

Cutters worn too early

•

Stony soil

•

Cutting height too low

•

Check the soil before

using the machine

•

Adjust the cutting height

Excessive noise or vibrations

•

Rotor unbalanced

•

Cutters damaged, worn or

missing

•

Bearings worn

•

Address to an authorized

service to adjust the rotor

•

Replace the cutters

•

Replace the bearings

Содержание TB-110

Страница 2: ...Sicma S p A Miglianico CH page 2...

Страница 3: ...Sicma S p A Miglianico CH page 3...

Страница 30: ...Sicma S p A Miglianico CH page 30...

Страница 31: ...Sicma S p A Miglianico CH page 31...