Sicma S.p.A.

Miglianico (CH)

page 25

-

Before injecting lubricating grease into the nipples, clean

them accurately to prevent mud, dust or other foreign

matters from mixing up with grease, thus diminishing the

lubrication effect

-

When making oil feed or change it is better to use the

same oil type, in order to avoid mixing oils with different

features.

-

When executing maintenance activities, keep the machine

rested on the ground in horizontal position.

-

After the first working hours check that all bolts and nuts

are tightened strongly; remember also to check often all

the machine safety guards.

MAINTENANCE OF THE MACHINE

FIRST CHECK

•

Check the correct tension of the driving belt

•

Check that all bolts and nuts are tightened strongly

•

After the first 50 hours of work change oil in the overgear unit

(oil type: TOTAL

TRANSMISSION TM 80W90)

EVERY 8 HOURS OF WORK

•

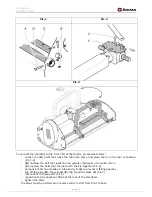

Grease the shaft support (driveline side) through the lubricating nipple A (picture 6)

•

Grease the shaft support (external side) through the lubricating nipple A (picture 7)

•

Grease the stabilizing roller through the lubricating nipple A (pictures 8-9)

EVERY 50 HOURS OF WORK

•

Check the correct tension of the driving belt

•

Check that all bolts and nuts are tightened strongly

•

Check the cutters/hammers wear state

•

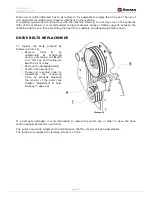

Check the overgear unit oil level through plug A (picture 10)

EVERY 500 HOURS OF WORK

•

Check that all bolts and nuts are tightened strongly

•

Change oil in the overgear unit

(oil type: TOTAL TRANSMISSION TM 80W90)

EVERY 1000 HOURS OF WORK

Replace the driving belts

Содержание TB-110

Страница 2: ...Sicma S p A Miglianico CH page 2...

Страница 3: ...Sicma S p A Miglianico CH page 3...

Страница 30: ...Sicma S p A Miglianico CH page 30...

Страница 31: ...Sicma S p A Miglianico CH page 31...