Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc.

page 40

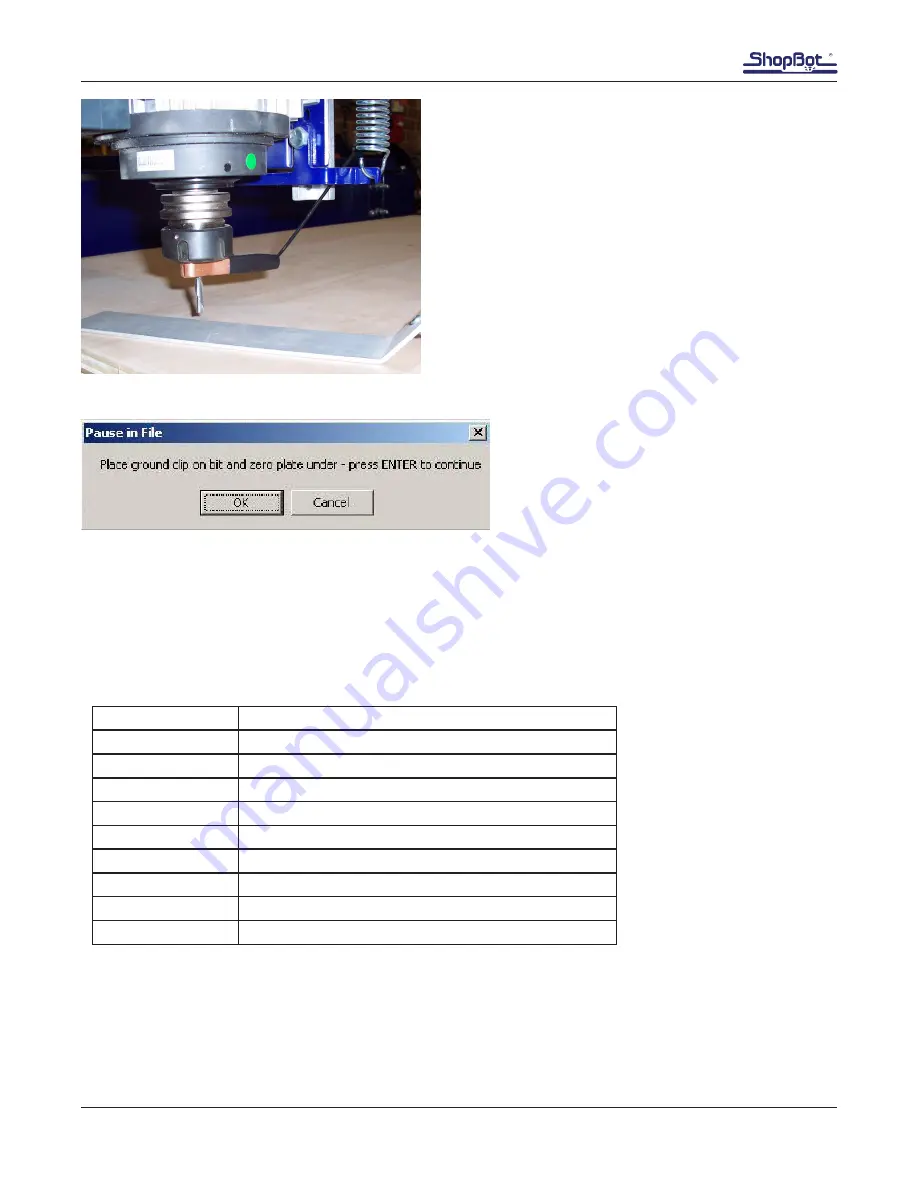

When the bit is located over the area needed to set as zero,

type “C2” (“Zero Z-Axis w/ Z zero Plate”).

Place the Z zero plate under the bit and place the

grounding clip on it. Click “OK” when both are in

place. The Z-axis will touch off the plate twice, and

record this distance for use on all the tools until

this Z offset is reset.

This records a Z offset height within the ShopBot user variables and applies this to all the other tools in the

tool rack.

Note that the Z offset is reset to the Z home position any time the C3 routine is run. To permanently change

the Z home position, refer to the Get plate offset (CN73) section of this document.

Regularly Used ATC Files

C1

Change tool

C2

Zero Z-axis using Z zero plate

C3

Home X, Y, and Z axes using proximity switches

C5

Spindle warmup routine

C6

Turns spindle on

C7

Turns spindle off

C9

Automatic tool change called from within part file

CN72

Zero tools in rack

CN73

Get plate offset (set Z-axis home position)

CN74

Calibration for tools in rack

Create a Tool Change File

The design software must first have the information to enable the ATC to do a tool change. For the software to

work correctly, the tooling must be designated to specify particular tool holders.

When setting up a tool database inside the design software, create a group named “Tool Changer” or “ATC”.