Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc.

page 38

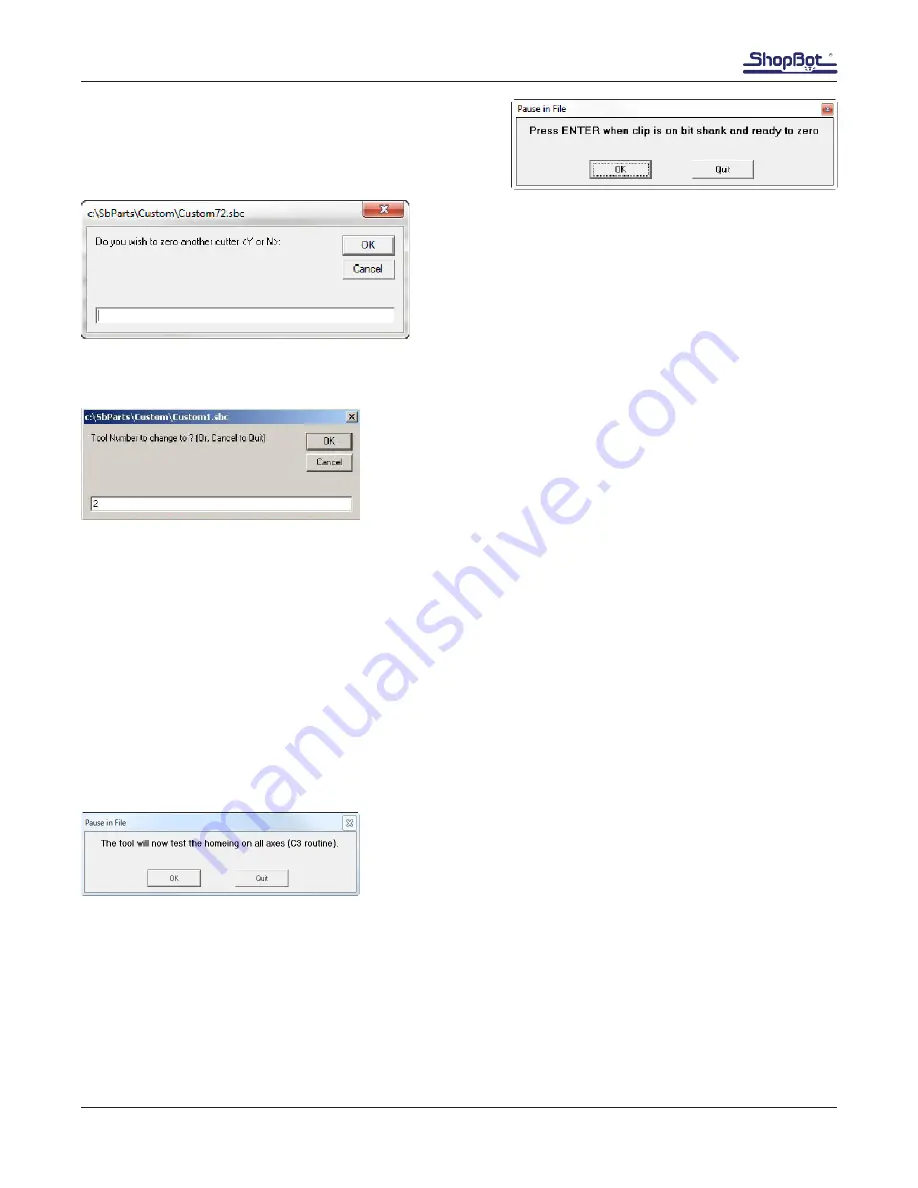

Clip the grounding clip to the shank of the bit and click “OK”.

If more bits need to be zeroed, answer “Y”. If not, then input

“N”.

Change Tools (C1)

Insert bit into conical tool holder and place it in the desired tool

holder location. Type C1 to run the custom number 1 “Change Tools”

routine. A screen will ask which tool should be selected. Once that

tool is entered, click “OK” and the ATC will drop off the current tool

being held and select the desired tool.

To check what tool the software thinks is in the spindle head, open “C:\Sbparts\Custom\ATC_Local_Data\

ATC_tool_variables.sbc”.

Look at line #3, &ToolIn= (Current tool) will show the tool last changed to.

Get Plate Offset (CN73)

Note: This file is included with ShopBot Versions 3.8.28 and later. Users of earlier version can add it by contact-

ing ShopBot technical support.

This routine will establish where the C3 (XYZ zero) routine will set the Z zero level. Normally this is at the table

bed. If a tool is not loaded in the spindle, select one before running this routine. Any tool can be used as they

have all been zeroed to the fixed plate.

Type “CN73” (custom number 73) in the ShopBot control software to

run the ATC get plate offset file.