23

VC-A412U/A413U

VC-H812U/H813U

4-18. ADJUSTMENT OF TAPE DRIVE TRAIN

1. Tape run rough adjustment

1

Remove the cassette housing control assembly.

2

After shortcircuiting TP803 and TP802 provided at

operation PWB, plug in the power cord.

3

Check and adjust the position of the tension pole.

(See 4-12.)

4

Check and adjust the video search rewind back

tension. (See 4-10.)

5

Connect the oscilloscope to the test point for PB

CHROMA envelope output (TP201). Set the syn-

chronism of the oscilloscope to EXT. The PB

CHROMA signal is to be triggered by the head

switching pulse (TP202).

6

Set the alignment tape (VROATSV) to play. (Put a

500g weight on the cassette tape to prevent lift of

cassette tape.)

Notes:

1. Previously set the tracking control in the center position,

and adjust the envelop waveform to maximum with X

value adjustment nut. Thereby the tape run rough ad-

justment is facilitated.

2. Especially the outlet side envelope waveform must have

higher flatness.

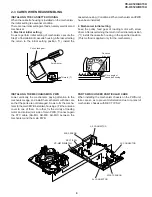

500g

Figure 4-31.

7

Press the tracking button (+), (–) and change the

envelope waveform from max to min and from min to

max. At this time make sure that the envelope

waveform changes nearly parallel.

8

Unless the envelope waveform changes nearly par-

allel, adjust the height of supply side and take-up

side guide roller so that the envelope waveform

changes nearly parallel. (For envelop adjustment

procedure refer to Figure 4-35.)

9

Turn the tilt screw to remove the tape crease at the

fixing guide flange.

Playback the tape and check for tape crease at the

fixing guide flange.

(1) If there is no tape crease

Turn the tilt screw clockwise so that tape crease

appears once at the flange, and then return the tilt

screw so that the crease disappears.

(2) If there is tape crease

Turn counterclockwise the tilt screw so that the

tape crease disappears.

(Reference) If the tilt screw is turned clockwise

crease appears at the lower flange.

Guide roller

Weight of 500g

Cassette Tape

2. Adjustment of A/C head height and azimuth

1

Perform the initial setting of A/C head position by the

method stated in "4-15 Replacement 3".

2

Connect the oscilloscope to the audio output termi-

nal.

3

Using the alignment tape in which 1 kHz linear audio

signal has been recorded, adjust the height screw so

as to get max audio output.

4

Using the alignment tape in which 7 kHz linear audio

signal has been recorded, adjust the azimuth screw

so as to get max audio output.

5

The adjustment of

3

and

4

twice or three times

repeat, and finally adjust

4

.

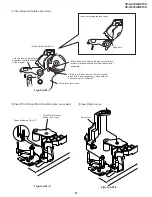

Figure 4-32.

For X value adjustment

Adjust the X value, turning the gear-

type screwdriver.

Figure 4-33.

3. Tape run adjustment

1

Connect the oscilloscope to PB CHROMA envelope

output test point, set oscilloscope sync to EXT,

trigger-input the PB CHROMA signal (head switch-

ing pulse).

2

Rough adjustment of X value

Tentatively fix A/C head arm screws

1

and

2

by the

method described in 4-15 "Replacement 3".

Playback the alignment tape (VROATSV) and

shortcircuit TP801 and TP802. As a result the auto-

tracking is automatically cancelled, so that the X

value adjustment mode is set.

Move the A/C head with the X value adjustment gear

driver (JiGDRiVER-6) by the method shown in Fig-

ure 4-33, and adjust the A/C head so as to get the

maximum envelope waveform. (Note: When the A/

C head is adjusted, adjust so that the maximum

envelop waveform is obtained nearest the position

of initial setting made in 4-15.)

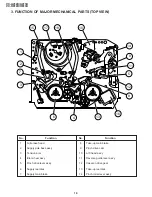

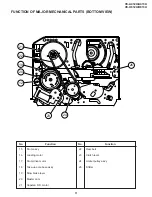

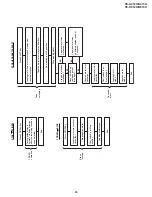

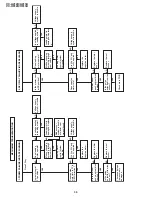

Содержание VC-A412U

Страница 6: ...6 VC A412U A413U VC H812U H813U 1 3 LOCATION OF MAJOR COMPONENTS AND CONTROL ...

Страница 50: ...VC A412U A413U VC H812U H813U VC A412U A413U VC H812U H813U 50 51 8 BLOCK DIAGRAM SYSTEM SERVO BLOCK DIAGRAM ...

Страница 53: ...56 VC A412U A413U VC H812U H813U POWER CIRCUIT BLOCK DIAGRAM ...

Страница 63: ...72 VC A412U A413U VC H812U H813U M E M O ...