10

10-1

10-2

25WF30

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

1

2

WHITE

BALANCE

BACK-

GROUND

(CUT OFF

BKGD) I

2

C

BUS ADJUST

-

MENT (A

V

SIGNAL)

1.

Receive E-5CH "Monoscope Pattern" signal.

2.

Select P-NORM with the remote controller

.

3

.

Connect the beam ammeter between

TP1601

and TP1602.

4.

Coarsely adjust the beam current to approx.

1.6mA with R1759 (Sub-Contrast VR)

5.

Receive the window pattern with

A

V

input.

(P

AL

burst is generated with the signal gen-

erator

.)

6.

With the data of G-drive and B-drive, adjust

the color temperature 12,300°K of the white

peak to white.

7.

Adjust the right dark area of the window to

12,300°K with R-cut of

f, G-cut of

f and B-cut

of

f.

8.

Read just the color temperature at the white

peak.

9.

Check 12,300°K at the low white.

Note1 :

Apply this adjustment after aging with

the beam current 1,400±50µA or more for 30

min or more. (On the white or green minocolor

screen)

Note:Data up/Down is possible

as below

.

R CUT OFF

UP

"1"

KEY

DOWN

"4" KEY

G CUT OFF

UP

"2"

KEY

DOWN

"5" KEY

B CUT OFF

UP

"3"

KEY

DOWN

"6" KEY

G-DRIVE

U

P

"7" KEY

DOWN

" "

K

E

Y

B-DRIVE

U

P

"8" KEY

DOWN

"0" KEY

*

12,300°K

X

: 0.272 ± 0.005

Y

: 0.275 ± 0.005

(With Monolta colour thermometer

CA-100)

*

The colour temperature is based

on the shipment initial setting ta-

ble.

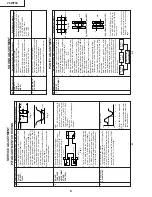

CRT CUT

OFF

(CUT

OFF

BKGD)

SER

VICE

MODE I

2

C BUS

DA

T

A

ADJUSTMENT

1.

Receive E-5CH "Monoscope Pattern" signal.

2.

Select P-NORM with the remote controller

.

3

.

T

urn on the service switch, and select the CUT

OFF BKGD mode at the service mode.

4.

Select the screen VR 0/10.

5.

Press "-/--" key of the remote controller to se-

lect the horizontal centering mode.

6.

T

urn the scteen VR clockwise, and adjust the

first lighting horizontal centering rasterslighly

light.

7.

Adjust the CUT OFF data of two other colors,

and coarsely adjust the horizontal centering

to become white. (Note 1)

8.

T

urn the screen VR in the opposite direction

to the point where the horizontal centering

raster goes out.

Note 1:

Apply the adjustment after aging with

the beam current 1,600±50µA or more for 30

min or more.

9.

Press "-/--" key of the remote controller to se-

lect the normal mode.

CUT OFF

, BKGD

ADJUSTMENT

*

Befor doing adjustment, make sure

the R/G/B-cut and the B/G-Drive is

at initial value.

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

1

MAX BEAM

R1759

1

.

Receive E-5CH "Monoscope pattern" with

standard mode.

2

.

Make the pictur normal with the remote

controller

.(A

V MODE: DYNAMIC)

3

.

Connect the beam ammeter between

TP1601

& TP1602.

Ammeter full scale-3mA range

TP1602 is connected at the - side of the am-

meter

.

TP1601 is connected at the + side of the am-

meter

.

4

.

Adjust the beam current to 1.6mA ± 20µA with

R1759 (sub-contrast VR).

Note :

Apply the adjustment after aging with the

beam current 1,400±50µA or more for 30 min

or more.

(On the white or green monocolor screen)

SUB-CONT ADJUSTMENT

3

WHITE

BALANCE

BACK-

GROUND

(CUT OFF

DVD BKGD)

I

2

C BUS

ADJUSTMENT

(DVD SIGNAL)

1.

The window pattern is received with DVD sig-

nal (component signal).

2.

Apply the adjustment in the same manner as

item 5 of adjustment 2 and the subsequence

above. (17,000°K ) (G-DRIVE, B-DRIVE, R-

CUT

OFF

, G-CUT

OFF

, B-CUT

OFF)

Apply the adjustment after the end of adjust-

ment 2.

Note2:

Use the window pattern of the

signal generator SX1006 for

adjustment.(P

AL, colour burst is

generated with signal genera-

tor

.)

2

SUB-

CONTRAST

(SUB-CONT)

I

2

C BUS

ADJUSTMENT

(A

V SIGNAL)

1.

Receive the window pattern with

A

V

input.

2

.

Make the picture normal with the remote

controller

.(A

V MODE: DYNAMIC)

3

.

Select the SUB-CONTRAST adjustment

mode with the remote controller

, and adjust

50% white to 165 ± 10cd.

Note 3:

Use "Y" of Minolta color analyzer

CA-100 in adjustment.

Note 4:

Use the P

A

L

window pattern of

the signal generator for adjust-

ment. (P

AL

and colour burst are

provided.)

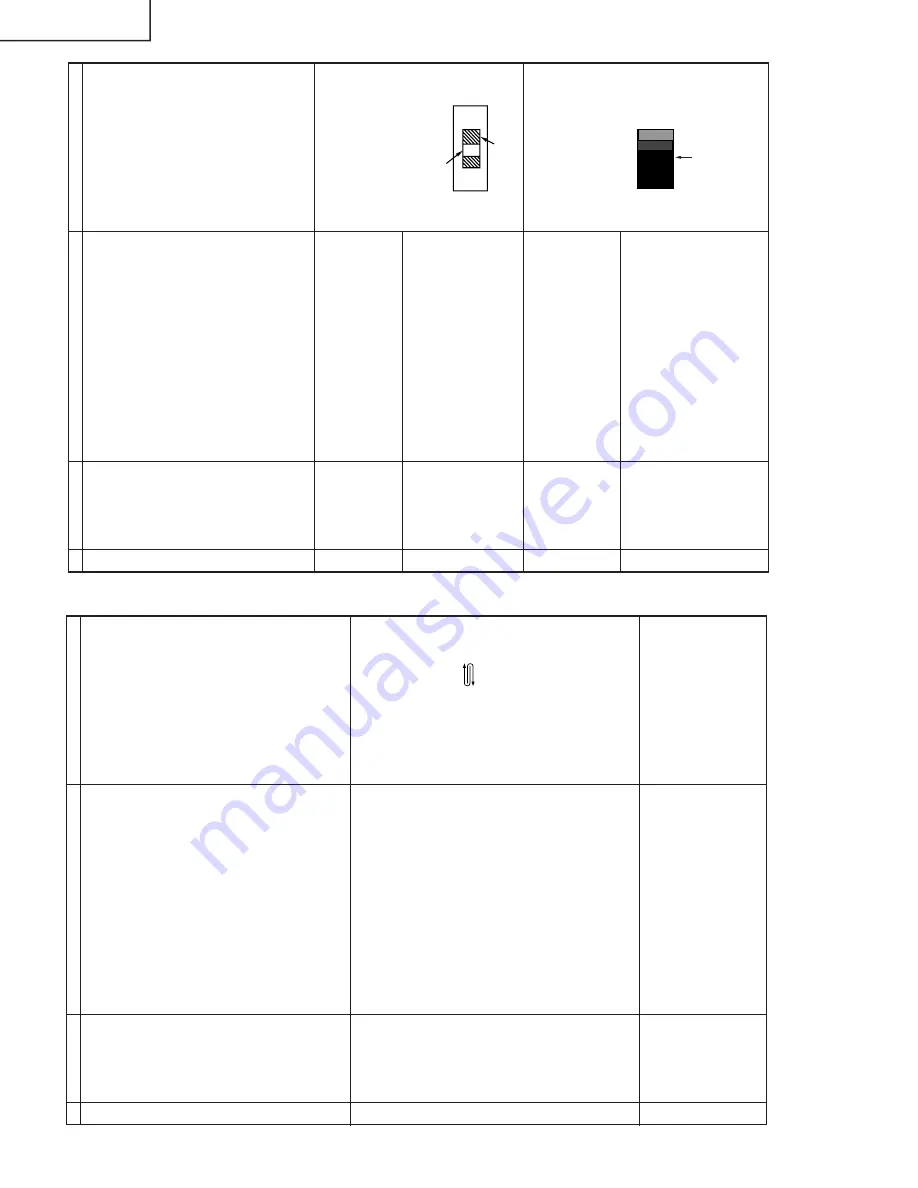

Note 5:Window Pattern

3

SUB-

CONTRAST

(SUB-CONT

DVD) I

2

C BUS

ADJUSTMENT

(DVD SIGNAL)

1.

Select the DVD mode.

2.

Receive the signal of the DVD signal genera-

tor

. (Component signal) (W

indow pattern)

3

.

Make the picture normal with the remote

controller

.(A

V MODE: DYNAMIC)

4

.

Select the SUB-CONTRAST adjustment

mode (DVD) with the remote controller

, and

adjust 50% white to 165 ± 10 cd.

4

SUB-

BRIGHTNESS

(SUB-BRI) I

2

C

BUS CON-

TROL

(A

V

SIGNAL)

1.

Receive the window pattern with

A

V

input.

2

.

Make the picture normal with the remote

controller

.(A

V MODE: DYNAMIC)

3.

Select the SUB-BRIGHT adjustment mode

with the remote controller

, and adjust the right

dark white area of the window pattern to 5.5

± 0.5 cd.

*

When E-2 CH (Crosshatch pat-

tern) or equivalent signal is re-

ceived.

1.Make the image normal with the

remote controller

.

2.Adjust the 3rd (1 thru 5 from the

left) black of the window pattern

to sink.

5

SUB-

BRIGHTNESS

(SUB-BRI

DVD) I

2

C BUS

CONTROL

(DVD SIGNAL)

1.

Select the DVD mode.

2.

Receive the signal of the DVD signal genera-

tor

. (Component signal) (W

indow pattern)

3

.

Make the picture normal with the remote

controller

.(A

V MODE: DYNAMIC)

4.

Select the SUB-BRIGHT adjustment mode

(DVD) with the remote controller

, and adjust

the right dark white area of the window pat-

tern to 5.5 ± 0.5 cd of window pattern.

CUT OFF POINT

50% white for SUB-CONT

Dark white for SUB-BRIGHT

Содержание 25WF30

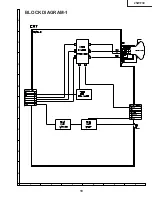

Страница 18: ...6 5 4 3 2 1 A B C D E F G H 18 25WF30 CHASSIS LAYOUT ...

Страница 19: ...6 5 4 3 2 1 A B C D E F G H 19 25WF30 BLOCK DIAGRAM 1 ...

Страница 20: ...21 25WF30 20 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 2 ...

Страница 21: ...23 25WF30 22 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 3 ...

Страница 22: ...25 25WF30 24 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 4 ...

Страница 23: ...6 5 4 3 2 1 A B C D E F G H 26 25WF30 BLOCK DIAGRAM 5 ...

Страница 26: ...6 5 4 3 2 1 A B C D E F G H 29 25WF30 SCHEMATIC DIAGRAM CRT Unit ...

Страница 30: ...6 5 4 3 2 1 A B C D E F G H 36 25WF30 SCHEMATIC DIAGRAM OPERATION Unit ...

Страница 31: ...6 5 4 3 2 1 A B C D E F G H 37 25WF30 PWB C CRT Unit Wiring Side PRINTED WIRING BOARD ASSEMBLIES ...

Страница 35: ...6 5 4 3 2 1 A B C D E F G H 44 25WF30 PWB D OPERATION Unit Wiring Side ...