8

8-1

8-2

25WF30

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

1

2

RF-AGC

T

AKE OVER

POINT

ADJUSTMENT

(I

2

C BUS

CONTROL)

1.

Receive the P

A

L

Colour bar signal.

Signal Strength: 54 ± 1 dbµV (75

Ω

open)

2.

Connect the oscilloscope to

TP201 (T

uner

’s

AGC

T

erminal) as shown in

Fig. 3

.

3.

Call "AG" mode in service mode.

Adjust the

"AG" bus data to obtain the

T

uner output pin

drop 0.1 ~ 1.0 V below maximum voltage.

4.

Change the antenna input signal to 63 ~

67 dBµV

, and make sure there is no noise.

5.

T

urn up the input signal to 90 ~ 95 dBµV to be

sure that there is no cross modulation beat.

Note:

For the 50

Ω

signal strength

gauge, when not using 50/75

impedance adapter

, signal

strength is 52 ± 1 dBµV (75

Ω

open), instead of 54 ± 1 dBµV

(75

Ω

open).

Precaution:

The loss of using impedance

adapter

.

T

uner IFT

(PRESET)

TU200

1.

Get the tuner ready to receive the CH. E-10

signal, but with no signal input.

Adjust the PLL data.

2.

Connect the sweep generator

’s

output cable

to the tuner antenna. (RF SWEEP)

3.

Adjust the sweep generator

’s

to 80dBµV

.

4

.

Connect the response lead (use LOW IMPED-

ANCE probe with wave detector ; see

Fig.1

)

to the tuner

’s

IF output terminal. (This terminal

must have the probe alone connected).

5.

Set the RF

AGC to 0 - 6 V with no saturation

with the waveform.

6.

Adjust the tuner IF coil to obtain the waveform

as shown in

Fig. 2

.

Note:

Be sure to keep the tuner cover in position

during this adjustment.

SER

VICE ADJUSTMENT

PIF ADJUSTMENT

CHECKING

3

PIF VCO COIL

ADJUSTMENT

1.

Do not receive any signal.

2

.

Connect the digital voltmeter to

TP803 (pin (54)

of IC800) in the main unit.

3.

Call the "PIF VCO" Mode at the service mode.

4.

V

erify that it is turned counterclockwise to 0V

and adjust

T800 to make DC voltage of

TP803

become 2.5 ± 0.1 V in the range.

DC voltage at

TP803

Adjust

T800 to B point, between B'

and B".

*

T

urn the coil counterclockwise for

the up direction and clockwise for

the down direction.

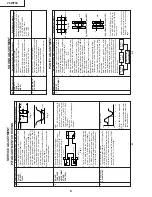

Fig.

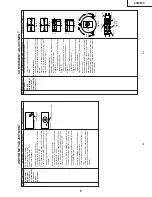

1

Fig.

2

E-9 CH

P C

-1.5+/-0.8dB

10k

100k

1n60

75ohm

IF OUT

1000p

Oscilloscope

Fig.

3

Oscilloscope

BIAS Bo

x

TV SET

Bias Bo

x :

about 4.5V

TP201

0.1V

+

–

+

–

5V

2.5V

Down

BB

"

C

U

P

B’

A

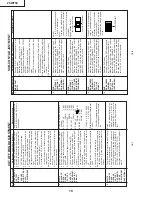

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

Note:The setting below is automati-

cally set when the SUB-VOL is

selected in the service mode.

*

SURROUND OFF

*

A

V MODE (ST

ANDARD)

*

S-NORMAL state

*

S-VOL Max

*

Bass + OFF

SOUND ADJUSTMENT

1

SUB VOL

(BUS

ADJUST

-

MENT)

1.

Receive P

A

L

Colour Bar signal.

Signal content: 400 Hz 100% Mod.

2.

Connect the probel of the meter (*) to (SI) con-

nector

.

3.

Select the SUB-VOL in the service mode.

4.

Adjust the SUB-VOL data to make the meter

indicate 5.2 V

rms (at L-CH)

Adjustment value: 5.0

±

0.3

V

rms

2

NOISE MUTE

CHECKING

1.

Receive the P

A

L

Colour Bar signal.

2

.

T

urn up the volume control to maximum, make

sure the sound is heard from the speakers.

Then put the unit in no signal state.

3.

Check the sound mute is ef

fective.

4.

Finally turn sound level of CTV to minimum.

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

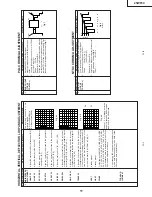

1

PURITY

ADJUSTMENT

1.

Select the green monocolour screen with re-

mote controller

, and set the beam current of

1,400µA with the contrast control.

2.

Degauss the CR

T

enough with the degausing

coil. For the adjustable magnetic field.

V

ertical Bv:

0.1G

Horizontal Bh:

0.1G

3.

Maintain the purity magnet at the zero mag-

netic field and keep the static convergence

roughly adjusted.

W

ith P-MG, adjust it to the center - rank

A.

4.

Observe the points a, b, as shown in

Fig.4-1

through the microscope. Move DY fore and aft

to set the landing at the point (rank

A).

5.

If the a/b balance is poor

, compensate it to the

center "Rank

AB).

6.

Align it to zero, keeping the raster rotation in

the east direction.

7.

T

ighten the defrection coil fastening screw

.

T

ightening torqu: 180N ± 20N (1

1kgf ± 2kgf)

8

.

Checking the CR

T

corner area, bond the mag-

netic sheet to set the landing at Rank

A

for

compensation.

Note:This adjustment must be done after

warming up the unit for 30 minutes or longer

with a beam current over 1400 ± 50 µA.

Note:Select the service mode, and press the

monocolour key of R/C for process,and the

monocolour screen (green) will be selected.

Every push of the monocolor key changes the

screen as follows.

PURITY

ADJUSTMENT

*

Press R/C RGB key for 1 sec-

ond in NORMAL MODE, the col-

our will change to RGB mono

colour mode.

Fig.

4-1

Fig.

4-2 Rank A (On the right of CR

T)

Fig.

4-3 Rank A (On the left of CR

T)

a

A

A=B

B

A

A=B

B

b

90 mm

90 mm

GREEN

ONL

Y

BLUE

ONL

Y

Single-colour

screen cleared

RED

ONL

Y

*

Adjustment for uniformity is

changed to another content.

Please refer to the following

page.

Содержание 25WF30

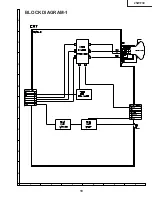

Страница 18: ...6 5 4 3 2 1 A B C D E F G H 18 25WF30 CHASSIS LAYOUT ...

Страница 19: ...6 5 4 3 2 1 A B C D E F G H 19 25WF30 BLOCK DIAGRAM 1 ...

Страница 20: ...21 25WF30 20 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 2 ...

Страница 21: ...23 25WF30 22 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 3 ...

Страница 22: ...25 25WF30 24 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 4 ...

Страница 23: ...6 5 4 3 2 1 A B C D E F G H 26 25WF30 BLOCK DIAGRAM 5 ...

Страница 26: ...6 5 4 3 2 1 A B C D E F G H 29 25WF30 SCHEMATIC DIAGRAM CRT Unit ...

Страница 30: ...6 5 4 3 2 1 A B C D E F G H 36 25WF30 SCHEMATIC DIAGRAM OPERATION Unit ...

Страница 31: ...6 5 4 3 2 1 A B C D E F G H 37 25WF30 PWB C CRT Unit Wiring Side PRINTED WIRING BOARD ASSEMBLIES ...

Страница 35: ...6 5 4 3 2 1 A B C D E F G H 44 25WF30 PWB D OPERATION Unit Wiring Side ...