9

9-1

9-2

25WF30

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

1

CONVER-

GENCE

ADJUSTMENT

(T

o be done

after the purity

adjustment.)

1.

Receive the Crosshatch Pattern signal.

2

.

Using the remote controller

, call NORMAL

mode.

Static convergence

1.

T

urn the 4 - pole magnet to a proper opening

angle in order to superpose the blue and red

colours.

2.

T

urn the 6 - pole magnet to a proper opening

angle in order to superpose the green colour

over the blue and red colours.

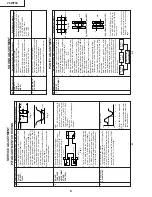

Dynamic convergence

1.

Adjust the convergence on the fringes of the

screen in the following steps.

a)

Fig. 5-1:

Drive the wedge at point "a" and swing the

deflection coil upward.

b)

Fig. 5-2:

Drive the wedge at point "b" and "c" and

swing the deflection coil downward.

c)

Fig. 5-3:

Drive the "c" wedge deeper and swing the

deflection coil rightward.

d)

Fig. 5-4:

Drive the "b" wedge deeper and swing the

deflection coil leftward.

2.

Fix all the wedges on the CR

T

and apply glass

tape over them.

3

.

Apply lacquer to the deflection yoke lock screw

,

magnet unit (purity

, 4 - pole, 6 - pole magnets)

and magnet unit lock screw

.

Finally received the Red - only and Blue - only

signals to make sure there is no other colours

on the screen.

CONVERGENT ADJUSTMENT

Fig.

5-1

Fig.

5-2

Fig.

5-3

Fig.

5-4

Fig.

5-5

Fig.

5-6

R G B

R

G

B

CR

T

Neck

Lacquer

Purity Magnet

4-Pole Magnet

6-Pole Magnet.

26

±

0.5mm

B

G

R

B G R

R G B

B

G

R

B G R

R

G

B

W

edge "a"

W

edge "b"

W

edge "c"

About

100 Deg.

About

100 Deg.

Lacquer

UNIFORMITY

ADJUSTMENT

No.

Adjustment point

Adjustment Condition / Procedure

W

aveform or others

Before adjustment begin,

Horizontal magnetic field =

V

ertical magnetic field = 0.1G

Make sure degauss it.

(North direction Red uniformity)

1

.

Horizontal mf = Set to monocolour screen Red

and adjust to + 0.25G.

2.

Pay attention to the edge of CR

T

, if the land-

ing is poor

, adjust by attaching the compen-

sation magnet at the back of the CR

T

. (Refer

to figure.)

(South direction Red uniformity)

1

.

Horizontal mf = Set to monocolour screen Red

and adjust to - 0.25G.

2.

Pay attention to the edge of CR

T

, if the land-

ing is poor

, adjust by attaching the compen-

sation magnet at the back of the CR

T

.

(The same mothod is aplied for adjustment of

monocolour screen Blue for blue uniformity

,

and changing both the magnetic field for North

and South direction.)

*

During the pasting of compensation magnet,

use the crosshatch pattern.

Make sure there is no blur or bend lines oc-

cur

.

If the blur or bend lines are serious, adjust

the location of compensation magnet to make

it better

.

1

Uniformity

adjustment

(T

o perform

after the purity

and conver-

gence

adjustment.)

(CR

T

surface)

(CR

T

back)

Miss landing

Compensation magnet

Содержание 25WF30

Страница 18: ...6 5 4 3 2 1 A B C D E F G H 18 25WF30 CHASSIS LAYOUT ...

Страница 19: ...6 5 4 3 2 1 A B C D E F G H 19 25WF30 BLOCK DIAGRAM 1 ...

Страница 20: ...21 25WF30 20 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 2 ...

Страница 21: ...23 25WF30 22 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 3 ...

Страница 22: ...25 25WF30 24 25WF30 8 7 10 9 6 5 4 3 2 1 A B C D E F G H 17 16 19 18 15 14 13 12 11 BLOCK DIAGRAM 4 ...

Страница 23: ...6 5 4 3 2 1 A B C D E F G H 26 25WF30 BLOCK DIAGRAM 5 ...

Страница 26: ...6 5 4 3 2 1 A B C D E F G H 29 25WF30 SCHEMATIC DIAGRAM CRT Unit ...

Страница 30: ...6 5 4 3 2 1 A B C D E F G H 36 25WF30 SCHEMATIC DIAGRAM OPERATION Unit ...

Страница 31: ...6 5 4 3 2 1 A B C D E F G H 37 25WF30 PWB C CRT Unit Wiring Side PRINTED WIRING BOARD ASSEMBLIES ...

Страница 35: ...6 5 4 3 2 1 A B C D E F G H 44 25WF30 PWB D OPERATION Unit Wiring Side ...