Manual revision 041

Section 5: Routine Maintenance and Calibration

SBE 37-SM RS-232

60

Section 5: Routine Maintenance

and Calibration

This section reviews corrosion precautions, connector mating and

maintenance, conductivity cell cleaning and storage, pressure sensor

maintenance, O-ring maintenance, plastic housing handling instructions,

replacement of AA cells, replacement of AF24173 Anti-Foulant Devices, and

sensor calibration. The accuracy of the MicroCAT is sustained by the care and

calibration of the sensors and by establishing proper handling practices.

Corrosion Precautions

Rinse the MicroCAT with fresh water after use and prior to storage. All

exposed metal is titanium; other materials are plastic. No corrosion

precautions are required, but direct electrical connection of the MicroCAT

housing to mooring or other dissimilar metal hardware should be avoided.

Connector Mating and Maintenance

Clean and inspect the connectors, cable, and dummy plug before every

deployment and as part of your yearly equipment maintenance. Inspect

connectors that are unmated for signs of corrosion product around the pins,

and for cuts, nicks or other flaws that may compromise the seal.

When remating:

1.

Lightly lubricate the inside of the dummy plug/cable connector with

silicone grease (DC-4 or equivalent).

2.

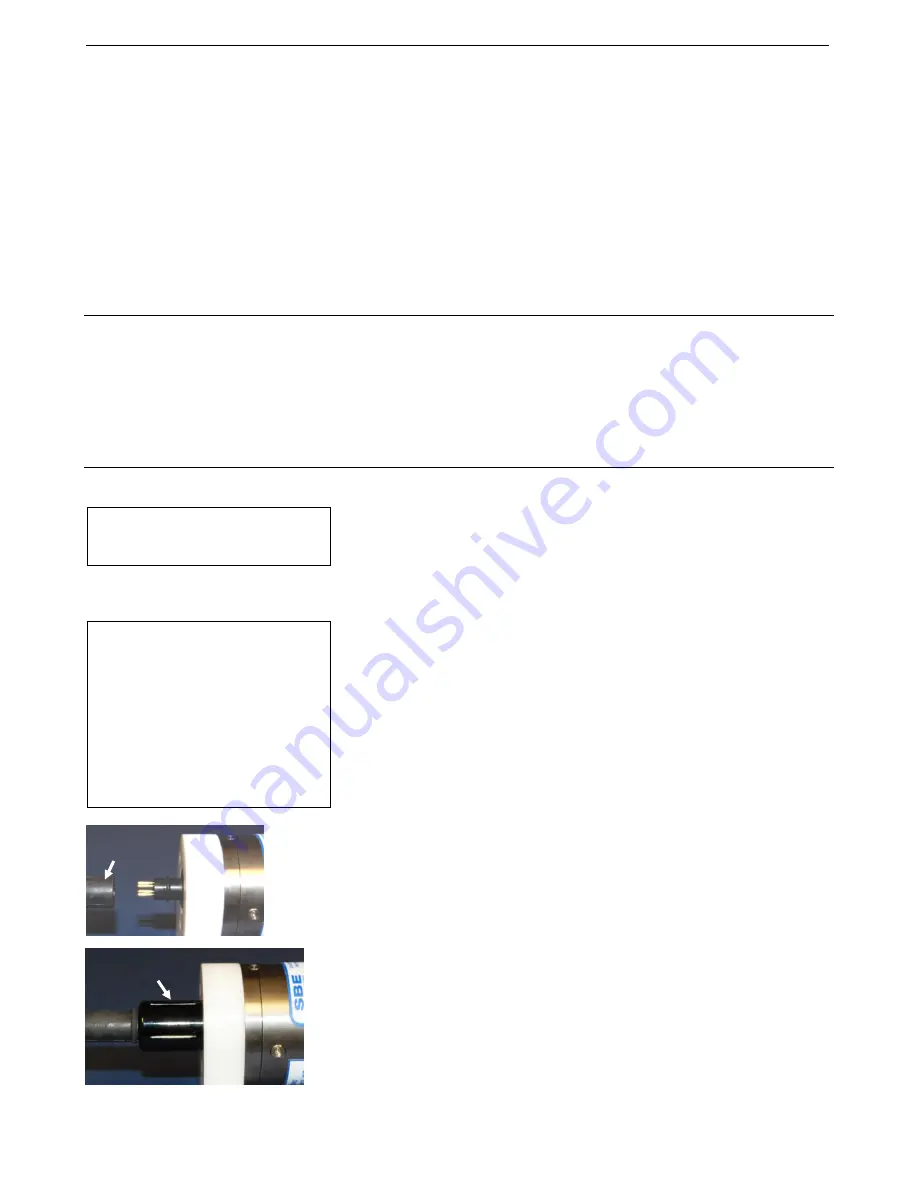

XSG Connector

- Install the plug/cable connector, aligning the raised

bump on the side of the plug/cable connector with the large pin

(pin 1 - ground) on the MicroCAT. Remove any trapped air by

burping

or

gently squeezing the plug/connector near the top and moving your fingers

toward the end cap.

OR

MCBH Connector

– Install the plug/cable connector, aligning the pins.

3.

Place the locking sleeve over the plug/cable connector. Tighten the

locking sleeve finger tight only.

Do not overtighten the locking sleeve

and do not use a wrench or pliers.

Verify that a cable or dummy plug is installed on the MicroCAT

before deployment.

CAUTIONS:

Do not use WD-40

or other

petroleum-based lubricants, as

they will damage the connectors.

For wet-pluggable MCBH

connectors:

Silicone lubricants

in a spray can

may contain

ketones, esters, ethers, alcohols,

or glycols in their propellant.

Do

not use these sprays, as they

will damage the connector.

Note:

See

Application Note 57: Connector

Care and Cable Installation

.

Locking sleeve

I/O cable