PAGE 28

E.

DO NOT PUNCH ANYTHING THICKER THAN THE PUNCH DIAMETER.

This "rule of thumb" can be extended, but the punch supplier or Scotchman should be consulted first, i.e.

(Do not punch plate thicker than 1/2 inch with a 1/2 inch diameter punch.)

This rule of thumb applies to mild steel only and must be reduced when punching alloy steels.

Contact the factory or your local dealer before attempting to punch any type of alloy steel.

F.

LUBRICATE THE PUNCH AND DIE.

This will hold stripping forces to a minimum and greatly extend punch life.

Lubrication must be applied after every 5 to 10 holes.

G.

PUNCH FULL AND COMPLETE HOLES. DO NOT PUNCH PARTIAL HOLES.

The side thrust encountered in punching a partial hole can force the punch over against the die and

result in punch or die breakage and possible injury to the operator.

H.

MAINTAIN SUFFICIENT MATERIAL BETWEEN THE PUNCHED HOLE AND THE EDGE

OF THE WORKPIECE.

The edge of the punch should clear the edge of the workpiece by a distance equal to the thickness of the

material being punched. Any edge distance of less than this amount will result in a deformed workpiece.

I.

STAY WITHIN RATED PUNCHING CAPACITIES.

The FI-8510-20M Ironworker is designed to operate in mild steel.

Within conservative limits, it can also operate in medium carbon annealed steel and some forms of

abrasion resistant steels.

Conditions of high shock can be encountered when punching alloyed steels. The machine rating must be

reduced accordingly. Punch to die clearance depends on the material thickness.

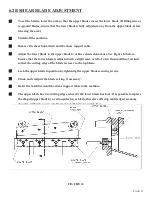

In mild steels, material thicknesses of 1/4 through 5/8 inch (6 to 16mm) should have a total punch to die

clearance of 1/32 inch. (Punch di 1/32" = Die diameter.) 3/4 through 1 inch (19 thru 25mm) mild

steel should have a minimum of 1/16 inch clearance. (Punch di 1/16" = Die diameter.)

In thin materials, the recommended punch to die clearance is 1/10 of the material thickness.

We do not recommend less than 1/64 of an inch (.4mm) total clearance due to working clearances

necessary in the punch ram and punch bushing.

The maximum material thickness this machine is designed to punch is 1 inch (25mm) mild steel. For

capacities, REFER TO THE PUNCH TONNAGE CHART IN FIGURE 10 ON THE FOLLOWING

PAGE.

Содержание FI-8510-20M

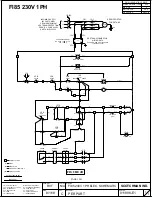

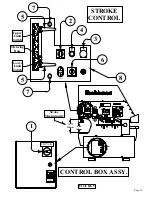

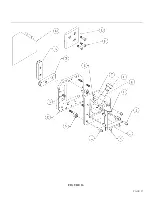

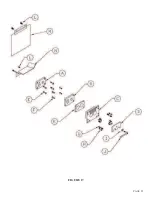

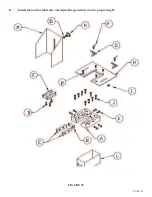

Страница 10: ...PAGE 9 FIGURE 1...

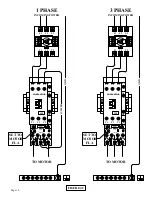

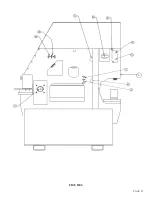

Страница 12: ...PAGE 11 FIGURE 2...

Страница 24: ...PAGE 21 FIGURE 6...

Страница 26: ...PAGE 23 FIGURE 7...

Страница 38: ...PAGE 35 FIGURE 15...

Страница 40: ...PAGE 37 FIGURE 16...

Страница 42: ...PAGE 39 FIGURE 17...

Страница 44: ...PAGE 41 11 Install the notcher table H and adjust the guard down to the proper height FIGURE 18...

Страница 48: ...PAGE 45 FIGURE 20...

Страница 50: ...PAGE 47 FIGURE 21...

Страница 52: ...PAGE 49 FIGURE 22...

Страница 56: ...PAGE 53 FIGURE 24...

Страница 58: ...PAGE 55 FIGURE 25...

Страница 62: ...PAGE 59 FIGURE 26...

Страница 64: ...PAGE 61 FIGURE 27...

Страница 68: ...PAGE 65 FIGURE 29...

Страница 74: ...PAGE 71 FIGURE 30...

Страница 76: ...PAGE 73 FIGURE 31...

Страница 80: ...PAGE 77 FIGURE 33...

Страница 82: ...PAGE 79 FIGURE 34...

Страница 84: ...PAGE 81 FIGURE 35...

Страница 88: ...PAGE 85 FIGURE 37...

Страница 90: ...PAGE 87 FIGURE 38...

Страница 92: ...PAGE 89 FIGURE 39...

Страница 94: ...PAGE 91 FIGURE 40...

Страница 96: ...PAGE 93 FIGURE 41...

Страница 100: ...PAGE 97 FIGURE 43 SERIAL S 4481 UP...