23

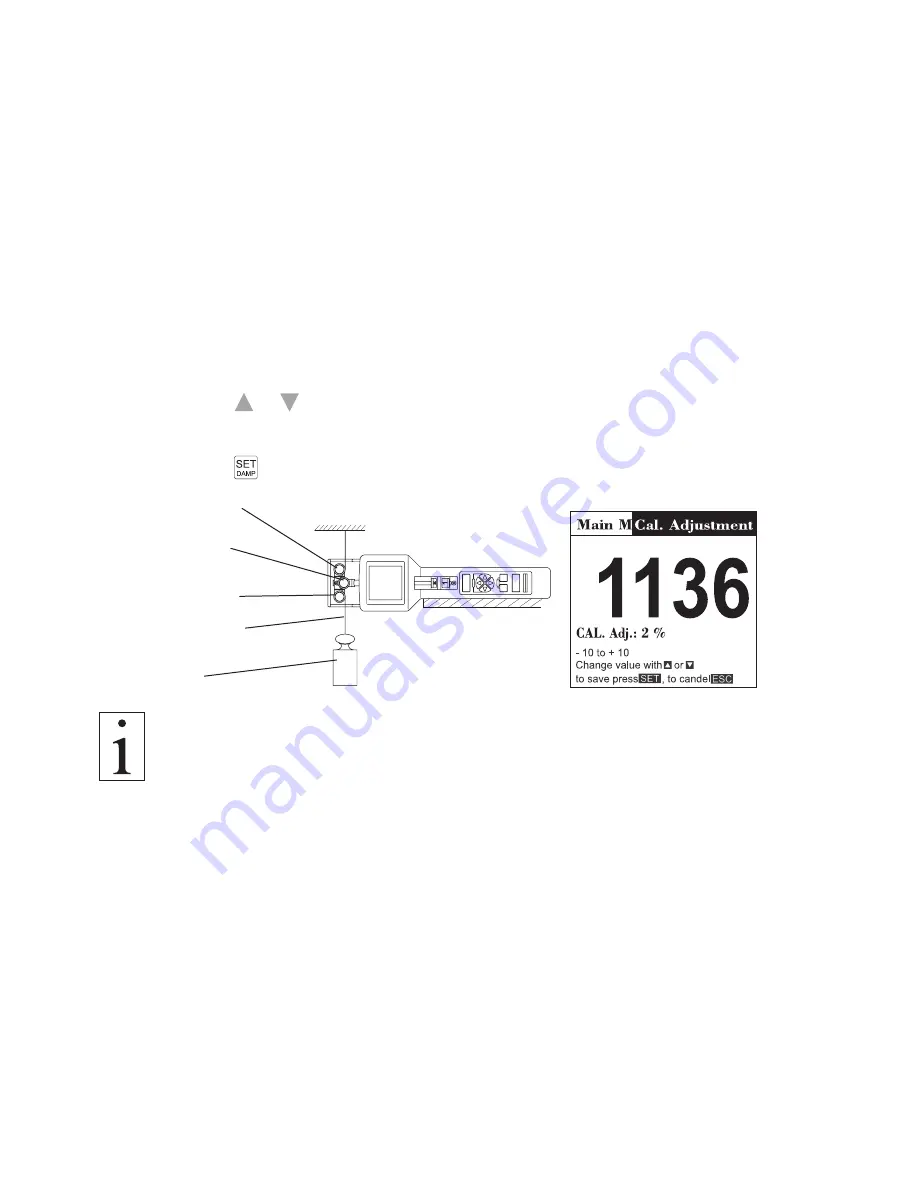

fig. 3.5.6b

Guide roller

Guide roller

Measuring

Roller

Material to

be measured

Weight

fig. 3.5.6a

3.5.6 Cal. Adjustment

By performing a calibration adjustment, you can adjust a material characteristic

calibrated for a particular material to a different material or diameter without creating

a new material characteristic.

Requirements

:

- Prepare the measuring setup as shown in Fig. 3.5.6a.

- Make sure that the thumbpiece is in the adjustment position (chapter 3.5.3).

- Set the material thickness as described in chapter 3.5.1.

- Select the desired material (chapter 3.4.1).

- Move the tension meter into the desired measuring position and carry out a zero

adjustment, if required.

Adjusting

:

- Select the „Cal. Adjustment“ menu item from the main menu (Fig. 3.5.6b)

- Insert the material to be measured (chapter 3.5.3) and push the thumbpiece into the

measuring position.

- Press the or key to perform the calibration adjustment until the value on the

display corresponds to the weight suspended to the material.

The adjustment can be performed in 1 % steps within the range from + 10 % to - 10 %.

- Press the

button to save the determined value.

Please note that this is a general value. So determine it separately for each mate-

rial characteristic and note it down for later reference. It is not possible to save it

per material characteristic.

To disable calibration adjustment, reset the value to 0 % in the „Cal. Adjustment“

menu.

3.5.7 Peak value

During a measurement cycle, the tension meter automatically calculates the Peak Mi-

nimum and Peak Maximum values. If these values should not be displayed in the bar

graph or in the statistics, disable their display in the main menu. Regardless, the Peak

values will be used and shown always in the software

Tension Inspect 3

.