30.30.01.01648/06

www.schmalz.com

EN | 49

7.

To inspect the contamination level in the

base section

, completely remove the end cover. You can

blow out the gripper with compressed air. When removing the functional cover, ensure that the hose

connection to the separating cylinder is disconnected.

8.

You can easily remove the separating cylinder assembly to check its condition. To do this, proceed

as follows:

Unscrew the four outer fastening screws on the cylinder mounting plate.

Remove the mounting plate and cylinder from the system; when doing so, disconnect the con-

necting hose for the functional cover

Inspect the hoses, quick exhaust valve and T section and blow them out with compressed air if

necessary.

Check the cylinder. This is fully retracted when depressurized. When you pull on the sealing plate,

you can notice significant resistance. After you release it, the cylinder immediately moves back to

its starting position. If not, the cylinder must be replaced.

Check the sealing. Replace defective sealings. Remove adhesive residues and any other con-

tamination when doing so. The adhesive surfaces must be kept clean and dry before the new

sealing can be attached.

Reinstall the cylinder, connect it to the pneumatic hose and quick-change valve, and reattach the

mounting plate. Ensure that the pneumatic hose is not bent or positioned in a way that would

impair the function of the separating cylinder.

Afterwards, perform a leak test.

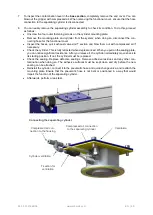

Compressed air connection

to the separating cylinder

Compressed air con-

nection to the housing

cover

Connecting the separating cylinder

T section for

ventilation

Cylinder ventilation

Ventilation

Содержание FMHD

Страница 60: ...60 EN www schmalz com 30 30 01 01648 06 ...