PAGE 14

ROUTINE MAINTENANCE

HAZARDOUS MOVING PARTS

Semiannually:

It is advisable to clean and lubricate the

idler arms (Fig. 26) to ensure their smooth operation. Use

the following procedures:

1. Make certain that

ALL

power to the dispenser is off.

2. Remove both side panels first, then remove the rear

panel of the machine.

3. Use a pencil to mark the position of the nut (Fig 26) on

the side of the belt idler arm spring adjustment

mechanism. Relieve the tension on the spring by turning

the adjustment screw near the label which warns:

DO

NOT ADJUST

. Disconnect the spring from the belt idler

arm by placing needle nose pliers on one end of the

spring and pulling the end out of the retainer.

4. Remove the nut from the pivot point of the belt idler

arm assembly.

5. Remove the belt idler arm and inspect the pivot point

sleeve. These areas should be free of rust, debris, or

dried lubricant. If any of these substances are found,

they must be removed.

6.

Clean and polish the sleeve surface with a fine grade

of emery cloth.

7. Reinstall the belt idler arm.

NOTE: BE CERTAIN NOT TO OVERTIGHTEN THE

LOCKING NUT. ON SOME UNITS IT IS POSSIBLE TO

OVERTIGHTEN THE LOCKING NUT AND CAUSE THE

IDLER ARMS TO BIND. THE ARMS SHOULD MOVE

FREELY.

8. Repeat the process for the torque idler arm.

9. Install the belt making certain that there is no grease

on the belt or pulleys. Step to the side of the unit and

view the belt to determine whether or not it is properly

aligned (straight from top to bottom).

10. Reinstall the silver torque idler arm spring and the

silver belt idler arm spring and turn the adjustment screws

returning the adjustment nuts to the pencil marks you

placed on the side of each adjustment mechanism in step

3 above.

11. Repeat steps 3 - 9 for the other side if your machine

has two freezing cylinders and then place the unit back

into operation. Check the product for proper consistency

and adjust as required. When the consistency is right,

replace the rear and both side panels.

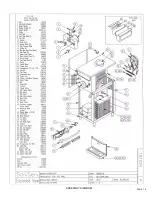

Fig. 26

Spring Adjustment Mechanism

Torque Idler Arm Pivot

Rotation

Rotation

Torque

Adjustment

Mark Nut

Position

With Pencil

Mark Nut Position

With Pencil

Belt Idler

Arm Pivot

Routine Maintenance (Trained Service Technician)

WARNING

Содержание A7081HEP

Страница 2: ......

Страница 17: ...PAGE 16 ASSEMBLY DIAGRAM ...

Страница 18: ...Notes ...

Страница 19: ...Service Log ...