INTRODUCTION and INSTALLATION

1. Install the legs using the instructions on the shipping

carton.

2. Place the machine in the desired location and level

the unit by turning the bottom part of each leg clockwise

or counterclockwise (Fig. 2). The machine

MUST

be

level to operate properly.

THESE UNITS MUST NOT BE OPERATED WITHOUT

THE LEGS INSTALLED UNLESS THE MACHINE IS

SUPPLIED WITH A COUNTERTOP MOUNTING PAD

OR SEALED TO THE COUNTERTOP.

3.

A minimum 6” (152

mm) clearance

must be

maintained at

the rear and sides

of the machine

for adequate

ventilation.

4. Electrical and refrigeration specifications are located

on the data plate on the rear panel of the machine.

Consult local authorities for information regarding

plumbing and electrical codes in your area.

Insure that the unit is in the off position and plug it into a

115 volt, 15 amp or 20 amp receptacle.

Note: All SaniServ machines should have their own

dedicated circuits to prevent low voltage conditions

caused by other operating equipment.

FAILURE TO PROVIDE FOR PROPER EARTH

GROUND ACCORDING TO LOCAL ELECTRICAL

CODES COULD RESULT IN SERIOUS ELECTRICAL

SHOCK OR DEATH. DO NOT USE EXTENSION

CORDS. INSTALL THE PROPER SIZE WIRE FOR

THE REQUIRED MACHINE AMPS. BE CERTAIN TO

OBSERVE LOCAL CODES IN SELECTING WIRE OR

CORD SIZE AND TYPE.

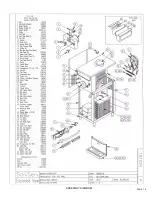

Installation

Fig. 2

Leg Installation

Minimum Clearance

4”(102 mm) for

Counter Top Models

This manual provides a description of the SaniServ Pressurized Frozen Beverage Dispenser. It has been prepared to

assist in the training of personnel on the proper installation, operation, and maintenance of the machines.

Read and fully understand the instructions in this manual before attempting to install, operate, or perform routine

maintenance on the machines.

Initially, the following sections of the manual must be performed in sequence:

1. Installation

4. Operation

2. Installer's Preoperational Check

5. Disassembly & Cleaning

3. Initial Start-up Preparation

6. Assembly & Lubrication

Introduction

PAGE 1

WARNING

WARNING

IMPORTANT

DO NOT TURN MACHINE ON UNTIL THE

INSTALLER’S PRE-OPERATIONAL CHECK

SECTION IS COMPLETE.

Содержание A7081HEP

Страница 2: ......

Страница 17: ...PAGE 16 ASSEMBLY DIAGRAM ...

Страница 18: ...Notes ...

Страница 19: ...Service Log ...