ENGLISH

16

2.

Remove

nuts

92.00

and

slide

out

the

back

pull

out

unit

from

the

casing

10.20.

Use

jack

screw

90.80

to

ease

disassembly.

Remove

gasket

40.00.

3.

Loosen

impeller

nut

92.20

and

helicoil

93.00.

4.

Slide

out

impeller

23.00

and

its

flat

gaskets

40.02

and

40.01.

5.

Loosen

screws

91.42

and

remove

wear

ring

54.20

from

casing

cover

16.10.

6.

Remove

key

94.01

and

slide

out

shaft

sleeve

52.30

with

mechanical

seal

43.30

from

shaft

21.10.

Remove

key

94.02.

Mark

position

of

mechanical

seal

before

dismantling.

7.

Remove

nuts

92.01

and

casing

cover

16.10.

8.

Remove

nuts

90.23,

take

away

cover

47.10

and

mechanical

seal

housing

48.70.

Change

gasket

40.05

for

a

new

one.

9.

Remove

screws

91.44

and

cover

36.00

on

motor

side

with

its

gasket

40.03.

10.

Slide

out

thrower

50.70

from

the

shaft.

11.

Withdraw

shaft

21.10

with

ball

bearings

32.11

and

32.20

with

care

from

bearing

bracket

housing

33.00.

12.

Remove

screws

91.43

and

cover

36.01

with

its

gasket

40.04.

13.

Remove

circlip

93.01,

loosen

shaft

nut

92.10

and

remove

lock

washer

93.01.

Extract

ball

bearing

32.11

and

32.20

from

the

shaft.

14.

Loosen

screw

90.11,

remove

washer

93.02,

and

foot

18.30.

15.

Dismantle

if

required

(worn

or

damaged

part)

the

lip

seals

42.30

and

42.31

from

covers

36.00

and

36.01.

9.3.2

RE

‐

ASSEMBLY

Refer

to

tightening

torques

table

for

screws

and

bolts.

Before

starting

assembly

of

the

pump

see

sectional

drawings

of

the

pump.

Respect

screws

and

bolts

tightening

torques.

1.

Install

ball

bearings

32.11

and

32.20,

the

circlips

93.01

onto

the

shaft

21.10.

Screw

nut

92.01.

When

installing

new

ball

bearing

on

the

shaft,

heat

them

up

to

80°C

to

ease

assembly.

2.

Press

lip

seals

in

bearing

covers

36.00

and

36.01.

Use

news

seals

if

necessary.

3.

Install

bearing

cover

36.01

on

pump

side

with

its

flat

gasket

40.04

and

screws

91.43.

4.

Fasten

foot

18.30

using

washer

93.02

and

screw

90.11.

Slide

shaft

assembly

inside

the

ball

bearing

housing

33.00.

5.

Install

ball

bearing

cover

with

the

flat

gasket

40.03

and

the

thrower

50.70.

6.

Install

cover

47.10

and

mechanical

seal

stationary

seat

48.70,

the

new

gasket

40.05

in

the

casing

cover

16.10

and

fasten

it

with

screws

90.23.

7.

Assemble

casing

cover

16.10

and

bearing

bracket

assembly

with

screws

90.21.

8.

Press

the

key

94.02

into

the

shaft

and

install

mechanical

seal

rotating

part

43.30

onto

shaft

sleeve.

Press

the

key

94.01

in

the

shaft

21.10.

Make

sure

that

seals

and

friction

faces

are

not

damaged

during

assembly

(scrubs

on

the

sleeve,

dirt,

…).

It

is

recommended

to

add

light

oil

on

the

shaft

to

ease

assembly.

9.

Install

wear

ring

54.20

and

screws

91.42.

10.

Install

impeller

23.00.

11.

Install

the

complete

back

‐

pull

‐

out

assembly

into

the

casing

with

the

casing

seal

40.00

between.

9.3.3

MOTOR

In

order

to

ensure

an

optimum

lifetime

of

the

integrated

motor

a

minimum

maintenance

is

necessary

:

clean

cooling

fins

regularly,

check

coupling

alignment

(if

any),

check

cable

gland

tightening,

…

Ball

bearing

lifetime

depends

on

axial

and

radial

forces

applied

on

motor

shaft

therefore

on

the

pump

design

(close

‐

coupled

pump,

pump

sets

with

elastic

coupling,

…).

Motor

can

be

fitted

with

lifetime

lubricated

ball

bearings

(identified

ZZ

or

2Z)

or

greased.

Greasing

nipples

are

located

at

the

ball

bearings

and

re

‐

greasing

quantities

are

indicated

on

motor

nameplate.

See

motor

instructions

manual

to

find

data

about

maintenance

work

to

be

performed.

9.4

TIGHTENING

TORQUES

Tightening

torques

depend

on

the

material

used

in

the

assembly

and

on

the

type

of

lubricant

that

is

used.

Refer

to

applicable

regulation

to

know

the

tightening

torques

for

the

fastening

of

cast

iron

or

stainless

steel

made

flanges.

The

values

given

below

should

be

only

indicative.

If

real

tightening

torques

are

required

please

ask

our

technical

services.

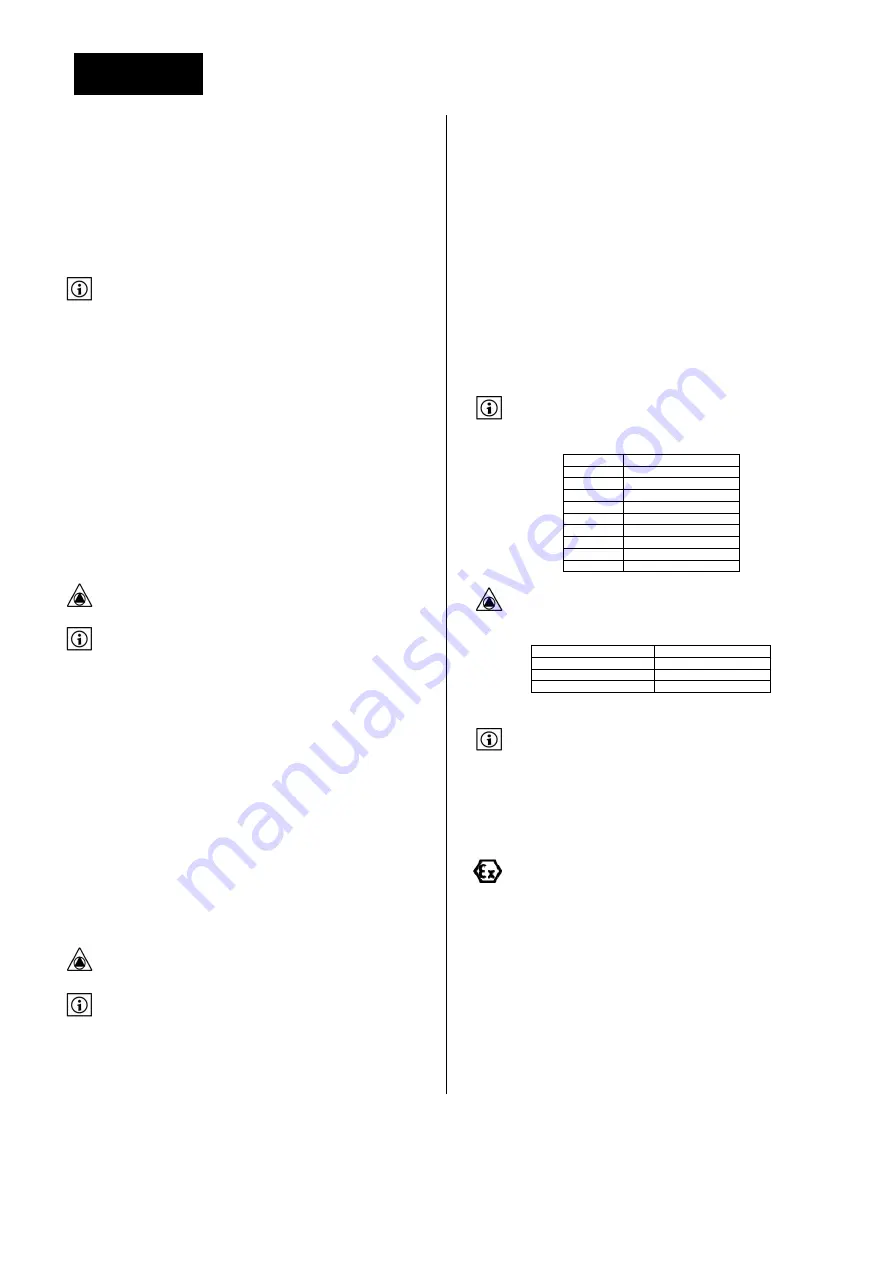

Threads

Tightening

torques

M6

8,5

Nm

M8

12

Nm

M10

25

Nm

M12

40

Nm

M16

90

Nm

M20

175

Nm

M24

300

Nm

M30

500

Nm

M36

700

Nm

Stainless

steel

bolts

:

apply

anti

‐

fretting

paste

before

assembly.

Tightening

torque

for

impeller

nut

item

92.20

:

Bearing

bracket

size

Tightening

torque

55

405

Nm

65

490

Nm

75

580

Nm

9.5

TOOLS

REQUIRED

A

typical

range

of

tools

that

are

required

for

pump

maintenance

is

listed

below.

Those

tools

are

standard

one

and

should

be

available

in

every

industrial

maintenance

Dpt.

•

Wrenches

to

suit

up

to

M48

nuts,

•

Socket

spanner

up

to

M

48,

•

Allen

keys

up

to

10

mm,

•

Range

of

screwdrivers,

•

Soft

mallet.

If

maintenance

work

must

be

performed

in

an

ATEX

classified

area

then

make

sure

that

use

of

all

necessary

tools

are

authorized

in

the

area.

More

specialized

equipment

:

•

Bearing

pullers,

•

Bearing

induction

heater

for

ball

bearing

assembly,

•

Coupling

grip

spanner.

Additional

equipments

used

for

coupling

alignment

:

•

Calipers,

•

Crowbar,

•

Straightedge,

•

Shims,

•

Sledgehammer.

Содержание NOEH

Страница 2: ......

Страница 3: ...NOEH INSTALLATION ET MISE EN SERVICE FRAN AIS N M S n 4095567 Ed 3 10 13...

Страница 4: ...2...

Страница 22: ...FRAN AIS 20 12 1 1 PLAN EN COUPE HYDRAULIQUE SIMPLE VOLUTE HYDRAULIQUE DOUBLE VOLUTE 12 1 2 NOMENCLATURE...

Страница 24: ...FRAN AIS 22 13 DECLARATION CE...

Страница 25: ......

Страница 26: ...NOEH INSTALLATION AND OPERATING INSTRUCTIONS ENGLISH N M S n 4095567 Ed 3 10 13...

Страница 27: ...2...

Страница 44: ...ENGLISH 19 12 1 1 SECTIONAL DRAWING SINGLE VOLUTE CASING DOUBLE VOLUTE CASING...

Страница 46: ...ENGLISH 21 13 EC DECLARATION OF CONFORMITY...

Страница 47: ......