4

5

4

1

2

3

4

5

7

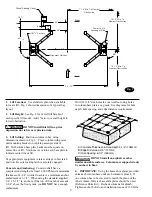

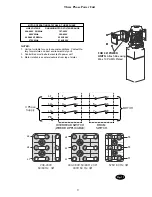

FRONT

6

7

5

5

Hose runs down

approach side to

cylinder on left column.

Cylinder Bleeders

Hose runs through holes in

extensions, then through

holes in overhead.

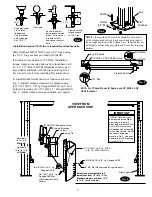

1st Cable

2nd Cable

Upper Sheaves

Lower Sheaves

Fig. 10

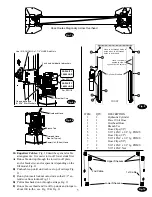

ITEM

QTY.

DESCRIPTION

1

2

Hydraulic Cylinder

2

1

Power Unit Hose

3

1

Overhead Hose

4

1

Branch Tee

5

3

Hose Clips(5/8")

5

3

5/16"-18NC x 3/8” lg. PHMS

6

1

Hose Clips(1/2")

6

1

5/16"-18NC x 3/8” lg. PHMS

7

2

Hose Clips(5/8")

7

2

5/16"-18NC x 1/2” lg. PHMS

7

2

5/16"-18NC Nut

Fig. 9

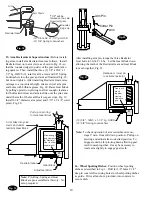

10. Equalizer Cables:

Fig. 10 describes general cable

arrangements. It is easier to tie-off lower studs first.

A)

Run cable stud up through the lower tie-off plate,

and/or bracket(s), and/or spacer(s) depending on the

lift model, Fig. 11.

B)

Push cable up until stud is above top of carriage Fig.

11.

C)

Run nylon insert locknut onto studs so that 1/2" ex-

tends out from locknut Fig. 11.

D)

Pull cables back down through carriage Fig. 11.

E)

Run cable overhead and tie-off top studs and torque to

about 100 in-lbs., see Fig. 10 & Fig. 11.

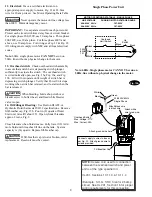

CAPACITY

15,000 LBS.

Use (4) 5/16”-18NC x 1-1/2” HHCS And Nuts

Push nuts hold bolts to brackets

On one bolt place

(2) 5/16” Star Washers

Fill Breather Cap

Overhead Hose

Crimped Hose

Sleeve (Typical)

Branch Tee

Power Unit (Short) Hose

For SPO15

CAPACITY

18,000 LBS.

For SPO18

Hose Routes Diagonally Across Overhead

Fig. 7b

Fig. 8a

Fig. 8b