10

10

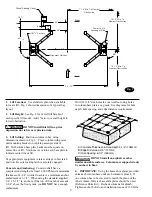

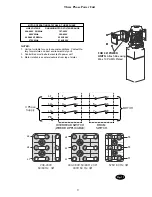

16. Wheel Spotting Dishes:

Position wheel spotting

dishes as described in Fig. 1. Drill (4) 3/8" holes 2 1/2"

deep in concrete floor using holes in wheel spotting dishes

as guide. Drive all anchors, provided, into concrete to

secure dish.

Note:

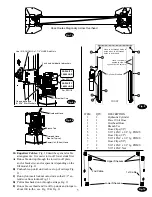

To check operation of arm restraints, raise car-

riage 1" min. from full down position. Pull up on

pin-ring and adjust arms to desired position. To

engage restraint, let pin-ring down allowing gear

teeth to mesh together. It may be necessary to

rotate arm slightly to engage gear teeth.

After installing arm pin, torque the three Restraint

Gear bolts to 30-34 Ft. Lbs.. Let the Gear Block down

allowing the teeth of the Restraint Gear and Gear Block

to mesh together, Fig. 21.

Fig. 18

Fig. 20

Fig. 21

Fig. 19

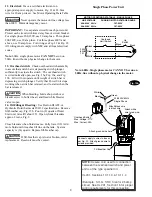

Note:

Pin, Ring, Spring and Gear

Block are pre-assembled at factory. No

set up required.

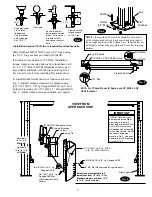

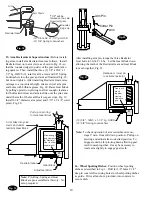

15. Arm Restraints & Superstructure:

Before install-

ing arms, install arm Restraint Gears as follows: Install

Restraint Gear onto arm clevis, as shown in Fig. 18, so

that the rounded edge (top side) of the gear teeth is fac-

ing upward. Then, install the three (3) 3/8"-16NC x 1

1/2" Lg. HHCS (12 total for all 4 arms) and 3/8" Spring

Lockwashers into the gear and arm as illustrated Fig. 18,

but do not tighten. After installing Restraint Gears, raise

carriage to a convenient height. Grease swivel arm pins

and holes with Lithium grease, Fig. 20. Raise Gear Block

by pulling upward on pin-ring to allow enough clearance

for the Restraint Gear and arm to slide over the yoke and

under the teeth of the Gear Block (or gear stop), Fig. 19.

Install 1-3/4" diameter arm pin(s) and 3/16" x 2-1/4" cotter

pin(s), Fig. 20.

(12) 3/8-16NC x 1-1/2" lg. HHCS

(12) 3/8" Spring Lockwashers

Restraint Gear

Rounded

Edge Up

"TOP" will be

marked on top side

of restraint gear

Arm

Arm Clevis

Arm slides into yoke

clevis and under

restraint Gear Block

Pull up on pin ring

to raise Gear Block

Restraint Gear

Gear Block

Adjustment Bolt

Allow enough

gap clearance

for Restraint

Gear to slide

under block

Arm Pin

Cotter Pin

Arm

Release or lower pin

to activate restraint

Gears will

mesh

together,

closing

clearance

gap.

(12) 3/8" - 16NC x 1-1/2" Lg. HHCS

(12) 3/8" Spring Lockwashers