6

5 Basic Operation

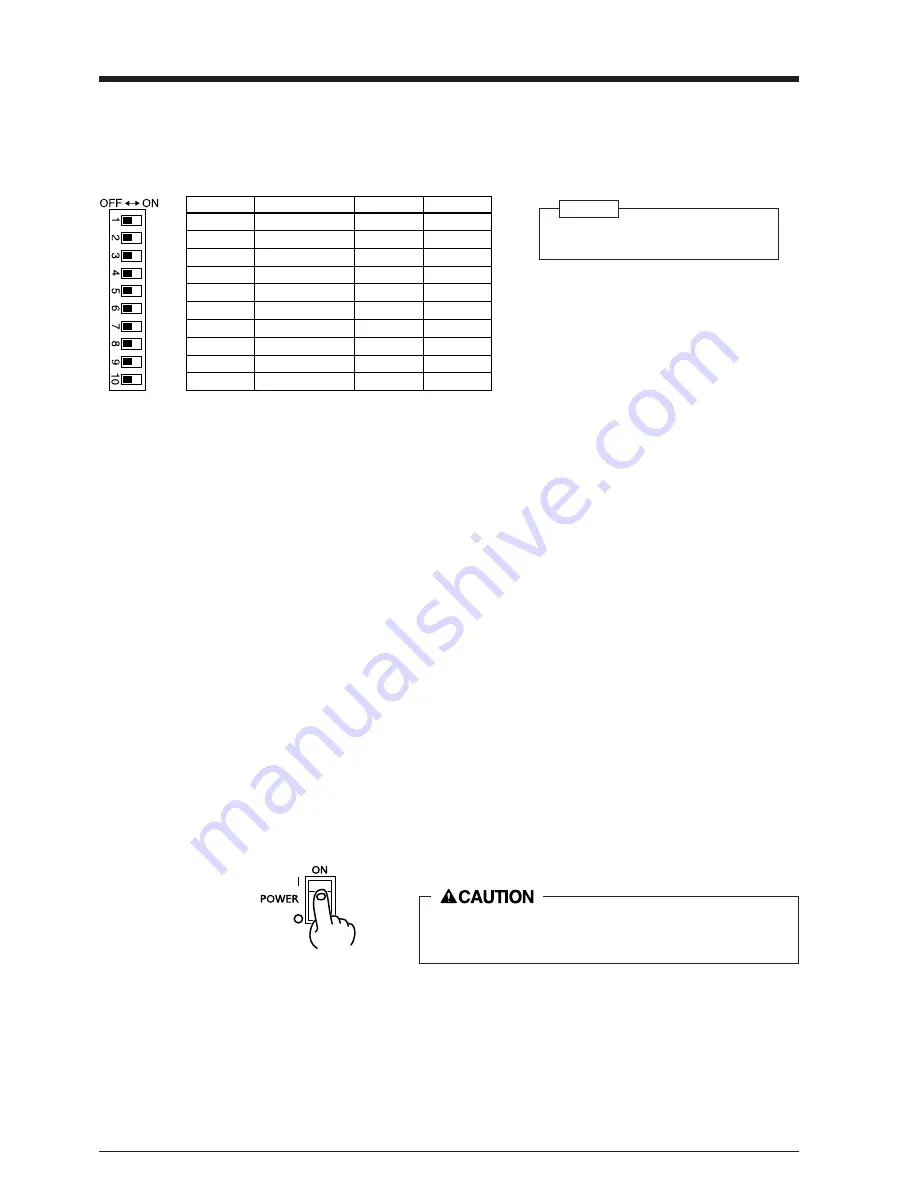

5-1 DIP Switch Settings

DIP switches settings must be made only

when the power is turned off.

NOTICE

5-2 Powering On

When the power switch is pressed to power on the unit, the

tool carriage moves. Use caution to ensure that your hands or

other objects do not become caught in the moving parts.

Press the side of the

switch marked “ | ”.

All DIP switches are set to OFF when shipped from the factory.

The DIP switches are located on the right face of the unit, near the bottom.

SW-1–4 : Sets the communication parameters for a serial connection. When the PC-50 is connected to the computer through the serial

port, be sure that the communication parameters for SW-1 to SW-4 are set correctly, matching the computer port settings.

(Data length is fixed to 8 bits. It is automatically determined whether the number of stop bits is 1 or 2.)

SW-5

: Detects automatically the front edge of loaded material. To detect the front edge of loaded material, set SW-5 to ON (en-

abled).

SW-6

: Detects length of cut material automatically. Switch to ON (enabled) when loading sheet material, and OFF (disabled) when

loading roll material.

SW-7

: Sets the amount of offset for the cutter blade. Set to OFF when using a tool with a blade offset of 0.25 mm, or to ON when

using a tool with a blade offset of 0.5 mm.

SW-8

: Sets the weight of the material. SW-8, which controls the material weight, should normally be set to OFF (light). Cutting

speed slows down when switch is turned ON, but the force used to move the material and the blade increases.

SW-9

: Acclimates the machine and the material before cutting or printing, which can produce more attractive printing or cutting

results. This is normally set to OFF (enabled).

(When the cut-sheet mode (SW-6) is set to ON (enabled), the prefeed mode is disabled, regardless of the setting of SW-9.)

*This option should be selected only when you are using

optional blade, ZEC-U3050.

Please contact your dealer for more information.

DIP switch

Function

OFF

ON

SW-1

Baud rate

9600

19200

SW-2

Parity

Disable

Enable

SW-3

Parity

ODD

EVEN

SW-4

Handshake

Hardwire

XON/XOFF

SW-5

Front edge sense

Disable

Enable

SW-6

Cut sheet mode

Disable

Enable

SW-7

Blade offset

0.25

0.5*

SW-8

Long output mode

Light

Heavy

SW-9

Prefeed mode

Enable

Disable

SW-10

(Not Used)

–

–

5 Basic Operation

Содержание Color CAMM PC-50

Страница 1: ...USER S MANUAL PC 50...

Страница 25: ...R4 971015...