18

Rockwell Automation Publication 1492-QS003B-EN-P - October 2019

Chapter 3

Load Material

Adjust the Label Sensor

Table 9 - Adjust Label Sensor

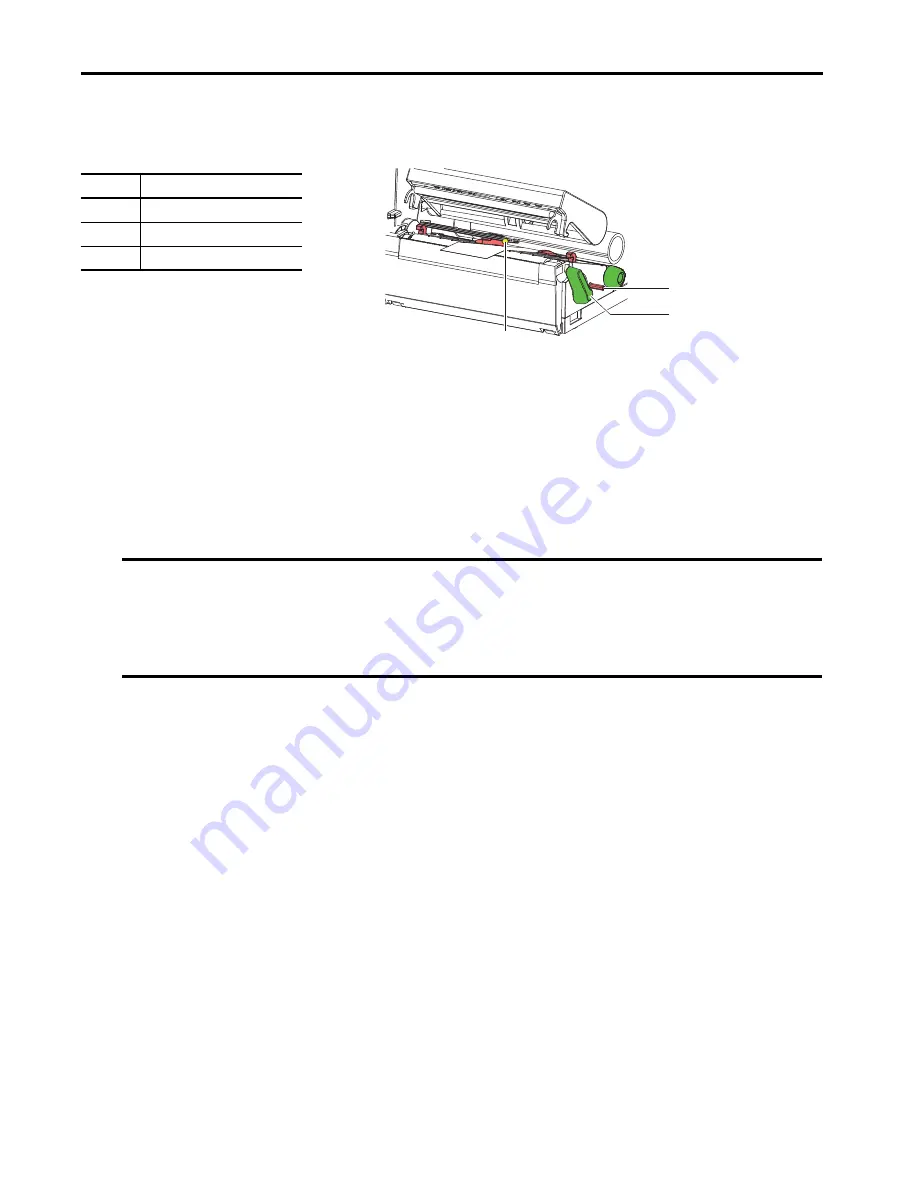

The label sensor position is marked with a yellow Status Indicator in the sensor retainer.

1. Press the label sensor adjustment knob (1) using a pointed object, so that the knob pops out of the bore of the

housing.

2. Position the label sensor (3) by turning the sensor adjustment knob (1) so that the sensor can detect the front edge

of the label in the direction of paper flow or cut-out mark.

3. Push the sensor adjustment knob(1) back into the bore of the housing using a pointed object until it snaps into

place.

Item

Description

1

Sensor adjustment knob

2

Print head lock lever

3

Label sensor

IMPORTANT

When the printer is delivered, the label sensor is positioned in the middle of the paper feed. The label sensor must only

be adjusted if:

• Material with reflex /cut-out marks not in the middle.

• Multi-strip material with an even number of strips.

• Material with irregularly shaped labels are used.

1

3

2

Содержание Allen-Bradley ClearMultiprint 1492-PRINTCMP

Страница 1: ...ClearMultiprint Marking System Catalog Number 1492 PRINTCMP Quick Start OriginalInstructions...

Страница 6: ...6 Rockwell Automation Publication1492 QS003B EN P October 2019 Preface Notes...

Страница 16: ...16 Rockwell Automation Publication1492 QS003B EN P October 2019 Chapter 2 Control Panel Notes...

Страница 26: ...26 Rockwell Automation Publication1492 QS003B EN P October 2019 Chapter 6 Fault Correction Notes...