Rockwell Automation Publication 35-UM001A-EN-P - May 2022

213

Appendix A Integrated Safety Instruction Validation Checklist

Safely-limited Speed (SLS)

Use the SLS instruction checklist in

to verify normal operation and

the abnormal operation scenarios.

Safely-limited Position

(SLP)

Use the SLP instruction checklist in

to verify normal operation and

the abnormal operation scenarios.

IMPORTANT

Perform I/O verification and validation before validating your

safety ladder program. SFX instruction must be verified within

your application.

When possible, use immediate operands for instructions to

reduce the possibility of systematic errors in your ladder

program.

Instruction operands must be verified for your safety ladder

program.

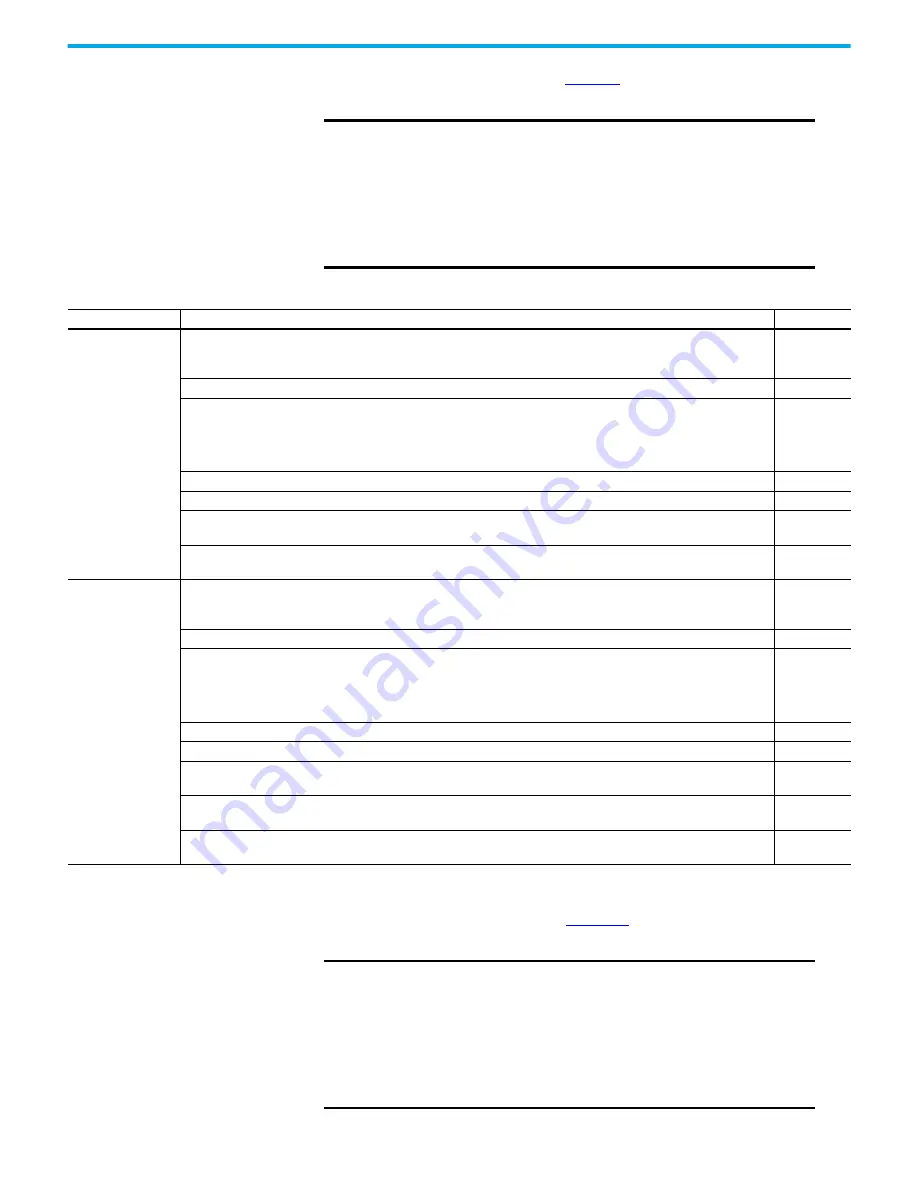

Table 99 - SLS Instruction Checklist

Test Type

Test Description

Test Status

Normal Operation

Initiate a Start command.

• Verify that the machine is in a normal machine run condition

• Verify proper machine status and safety application program status

Operate the machine within the desired speed range.

Set up a trend with expected time scale and the following tags to graphically capture this information:

SFX_Name

.ActualSpeed

SLS_Name

.SLSLimit

SLS_Name

.ActiveLimit

SLS_Name

.Output 1

Initiate SLS demand.

Verify that the drive achieves the speed below the

SLS_Name

.ActiveLimit without asserting the

SLS_Name

.SLSLimit output.

While the system is in SLS monitoring state and with the sensor subsystems in a safe state, remove the SLS demand.

• Verify proper machine status and safety application program status

Resume normal machine operation.

• Verify proper machine status and safety application program status

Abnormal Operation 1

Initiate a Start command.

• Verify that the machine is in a normal machine run condition

• Verify proper machine status and safety application program status

Operate the machine within the normal speed range.

Set up a trend with expected time scale and the following tags to graphically capture this information:

SFX_Name

.ActualSpeed

SLS_Name

.SLSLimit

SLS_Name

.ActiveLimit

SLS_Name

.Output 1

Initiate SLS demand.

Verify that the drive achieves the speed below the

SLS_Name.

ActiveLimit without asserting the

SLS_Name

.SLSLimit output.

While the system is in the SLS monitoring state, initiate a motion command that violates the

SLS_Name

.ActiveLimit.

• Verify that the

SLS_Name

.SLSLimit output is asserted and the programmed stop action is initiated

While the system is stopped with the sensor subsystems in a safe state, initiate a Start command.

• Verify proper machine status and safety application program status

While the system is stopped, initiate a Reset command.

• Verify proper machine status and safety application program status

IMPORTANT

Perform I/O verification and validation before validating your

safety ladder program. SFX instruction must be verified within

your application.

When possible, use immediate operands for instructions to

reduce the possibility of systematic errors in your ladder

program.

Instruction operands must be verified for your safety ladder

program.

Содержание Allen-Bradley 35E

Страница 10: ...10 Rockwell Automation Publication 35 UM001A EN P May 2022 Table of Contents Index 223 ...

Страница 222: ...222 Rockwell Automation Publication 35 UM001A EN P May 2022 Appendix B Configure a Message Instruction Notes ...

Страница 225: ...Rockwell Automation Publication 35 UM001A EN P May 2022 225 Armor PowerFlex AC Drives User Manual ...