Rockwell Automation Publication 35-UM001A-EN-P - May 2022

119

Chapter 6 Safety Functions

SLS, SLP, and SDI Faults

The drive does not support drive-based SS2, SOS, SLS, SLP, and SDI safe stop/

safety limit functions. The safety controller supports the SLS, SLP, and SDI

safety function instructions. If the drive reports one of these faults, then the

safety controller detected the fault and reported to the drive over the safety

output connection, or the request tag was set through the safety output

assembly. Additional information for these faults must be obtained from the

safety controller that is associated with the drive. In addition, the safety

controller is responsible for issuing a torque disable request.

Safety Feedback Faults

When configured for safety feedback, the drive performs periodic diagnostics

to make sure that the feedback device is operating correctly. Use an explicit

message to read the fault type information from the drive. For example, if an

error is detected, the Safe Feedback object (class code 0x58) updates the

Feedback Fault Reason attribute (attribute ID 0x09) with the reason for the

fault.

Safety Fault Reset

If the drive detects a fault, the input assembly tag

device

:SI.SafetyFault is set

to one.

A Safety Fault can result from the SS1 stopping function, STO function, safety

feedback, SBC function, or other safety diagnostics.

To acknowledge or clear this fault, remove the source of the safety fault and

send a fault reset to the safety logic.

See

for more information about the Integrated Safety

Functions option module, state restart functionality.

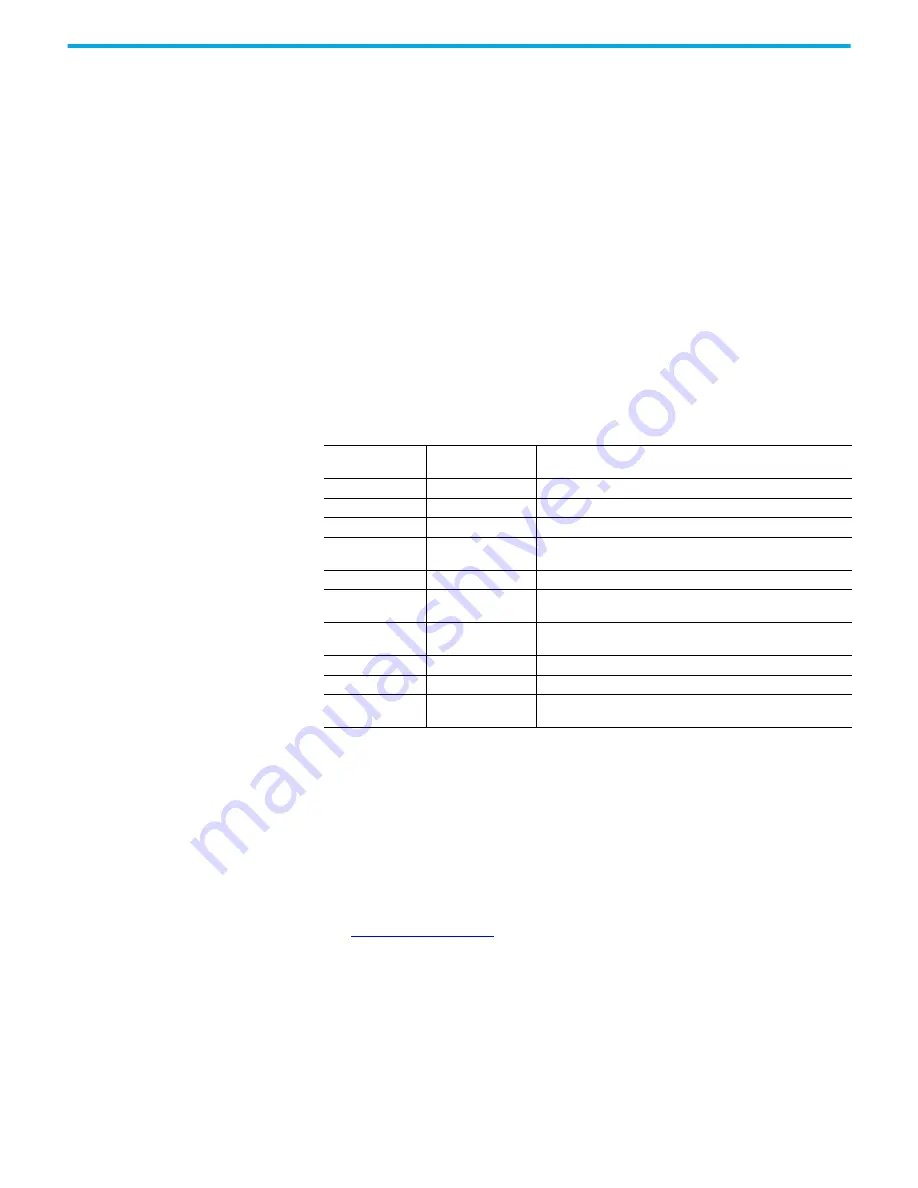

Table 38 - Safety Feedback Faults

Safety Feedback

Fault Reason Value

Safety Feedback

Fault Reason Name

Description

1

No Fault

No Fault is present.

2

Invalid Configuration

The encoder's configuration is invalid.

3

Exceeded Max Speed

The encoder speed has exceeded the configured maximum speed.

4

Exceeded Max

Acceleration

The encoder acceleration has exceeded the configured maximum

acceleration.

5

Sin²+Cos² Error

The encoder has failed the vector length or aspect ratio checks.

6

Quadrature Error

The encoder has exceeded the maximum number of quadrature

signal errors.

9

Supply Voltage Error

The associated dual channel feedback instance has detected a fault

in the other encoder

11

Feedback Signal Loss

A feedback signal is missing, shorted, or open.

107

Max input frequency

Max Frequency of the configured encoder has been exceeded.

109

Position Rollover

Position has exceeded the maximum value supported by this

product. Please reset the device

Содержание Allen-Bradley 35E

Страница 10: ...10 Rockwell Automation Publication 35 UM001A EN P May 2022 Table of Contents Index 223 ...

Страница 222: ...222 Rockwell Automation Publication 35 UM001A EN P May 2022 Appendix B Configure a Message Instruction Notes ...

Страница 225: ...Rockwell Automation Publication 35 UM001A EN P May 2022 225 Armor PowerFlex AC Drives User Manual ...