DATA LOGGING DESCRIPTION

MAN-1111 Rev H

©Copyright 2015 LSI-Robway Pty Ltd

Page 116

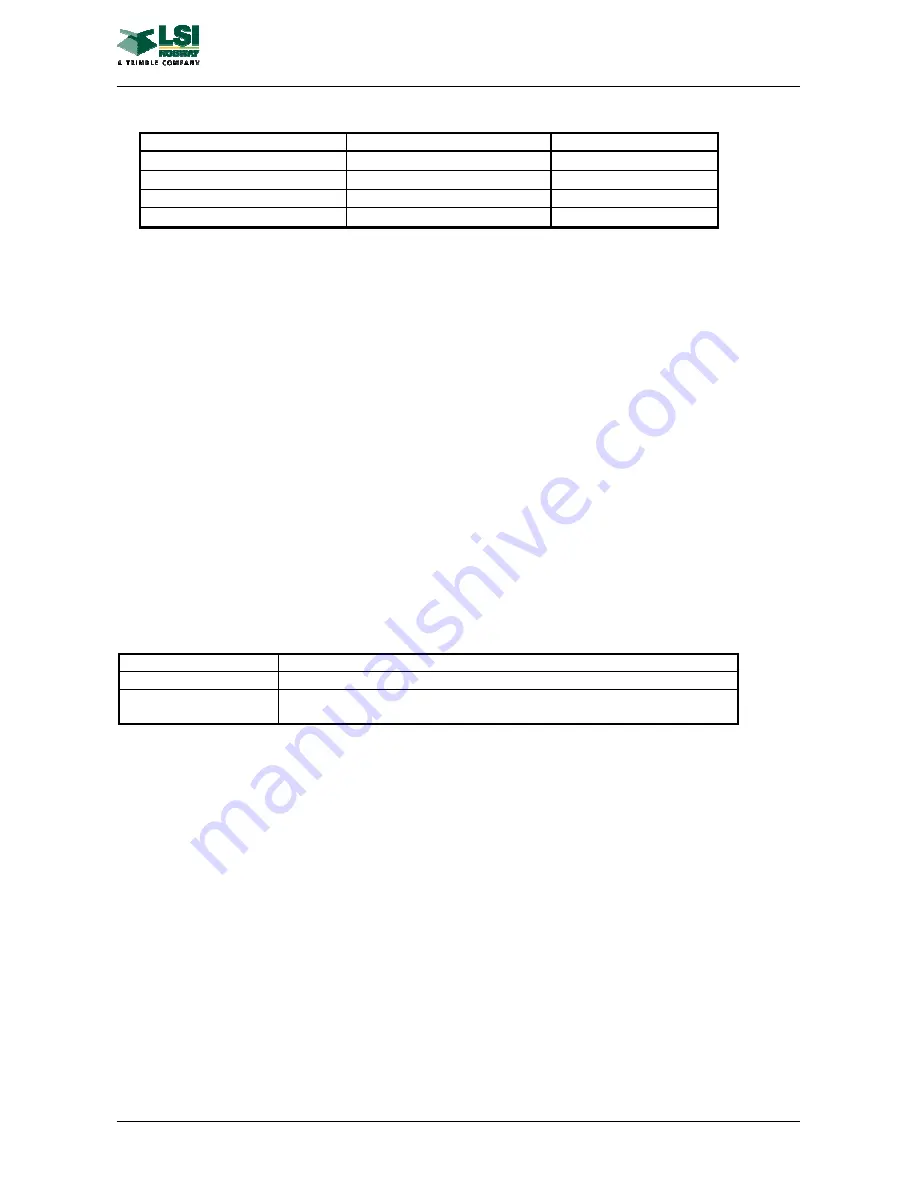

A summary of the logging percentage Function Codes is displayed in the following table:

Function Code Name

Description

Default Setting

Low Load Lift counter

swl percentage to record

20.0%

Medium Load Lift counter

swl percentage to record

40.0%

High Load Lift counter

swl percentage to record

65.0%

Logging Percentage

swl percentage to log

90.0%

These default settings would give rise to the following logging operation:

Low Load Lift Counter: counts the number of lifts which produce a SWL % which is greater than or equal to

20% but less than 40%.

Medium Load Lift Counter:

counts the number of lifts which produce a SWL % which is greater than or

equal to 40% but less than 65%.

High Load Lift Counter:

counts the number of lifts which produce a SWL % which is greater than or

equal to 65% but less than 90%.

Logger Records full data log of any lift which produces a SWL % which is greater than or equal to 90%

Setting Up the Data Logger

Data logging will occur at all times the display is operational. This includes the cases when, the over-ride is

activated, the display is reporting an error and during the initial calibration of the system.

For the logger to operate properly the display must be fully and correctly calibrated. This includes date and

time being set correctly. However, since the logger was recording during calibration it may be desirable to

erase the logger contents after completing the angle and load calibrations on the RCI-4100 since the logger

would have recorded some invalid information during the calibration of the sensors.

To erase the data logger contents, simply activate the appropriate Function Code once calibration is

complete (refer

Erasing Data Logger Information

).

The operator can access three more Function Codes which control how the actual logging of loads operates.

These three Function Codes are summarised in the following table

Stable Load Time

time during which load must stay stable in order to log

Stable Load Variation

load must stay within this variation to be considered stable

Reset Time

load must stay below the Low Load Counter threshold for this time

before the log cycle ends

The first two Function codes in the table are used for definition of a stable load. When a load is hoisted it is

probable that the initial load reading will be greater than the actual load on the hook because of the

"snatching effect." The stable load is recorded only when these dynamic factors have died down and the

load can be considered to be hanging from the hook in a relatively motion free position.

The "Stable load time" and "Stable load variation" Function codes can be used to adjust the load recording to

minimise the effect of dynamic factors. The load will be considered stable if the load reading does not

change by more than the "Stable load variation" setting (which is normally 0.5t by default) for a period of time

set by "Stable load time" (which is normally 2 seconds by default).

The third Function code, "Reset time," is used for terminating a log cycle. When the load causes a SWL %

which is less than the logging values (specifically the Low Load Lift counter percentage), then it is assumed

that the driver must be putting the load down again. In order to ensure that a single load is not logged

multiple times because the SWL % was hovering around the logging threshold, a log cycle will not complete

until the load SWL % remains below the threshold for a certain period of time, namely of course the "Reset

time" (by default the reset time is normally 5 seconds).

Log Cycle Description

Three types of log cycles are possible:

•

Load is lifted inside load chart boundaries (valid SWL is seen at all times)

•

SWL drops to 0 indicating the load chart has been exceeded, sensor error has occurred or slew error

has occurred.

•

Over-ride key switch is operated.

Содержание RCI-4100

Страница 2: ......

Страница 6: ......

Страница 8: ......

Страница 28: ......

Страница 36: ......

Страница 38: ...OPERATION AND INSTALLATION RCI 4100 SYSTEM MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 38 ...

Страница 58: ......

Страница 70: ......

Страница 82: ......

Страница 88: ......

Страница 92: ......

Страница 94: ......

Страница 95: ...DECLARATION OF CONFORMITY RCI 4100 SYSTEM MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 95 ...

Страница 96: ...DECLARATION OF CONFORMITY RCI 4100 SYSTEM MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 96 ...

Страница 97: ...DECLARATION OF CONFORMITY RCI 4100 SYSTEM MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 97 ...

Страница 98: ...DECLARATION OF CONFORMITY RCI 4100 SYSTEM MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 98 ...

Страница 99: ...DECLARATION OF CONFORMITY RCI 4100 SYSTEM MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 99 ...

Страница 100: ......

Страница 102: ......

Страница 103: ...ATEX CERTIFICATE 4100 DISPLAY AND DISPLAY BARRIER MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 103 ...

Страница 104: ......

Страница 106: ......

Страница 107: ...IECEX CERTIFICATE RCI 4100IS DISPLAY MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 107 ...

Страница 108: ......

Страница 110: ......

Страница 111: ...IECEX CERTIFICATE MODEL 4120 POWER SUPPLY AND I2C BARRIER MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 111 ...

Страница 112: ......

Страница 113: ...DATA LOGGING DESCRIPTION MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 113 APPENDIX F Data Logging ...

Страница 114: ......

Страница 120: ...DATA LOGGING DESCRIPTION MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 120 Example Lift Cycles ...

Страница 126: ......

Страница 128: ......

Страница 129: ...EX D BARRIER GLAND INSTALLATION INSTRUCTIONS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 129 ...

Страница 130: ......

Страница 132: ......

Страница 140: ......

Страница 142: ...WIND SPEED MONITORING OPTION MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 142 ...

Страница 144: ......

Страница 147: ...WIND DIRECTION MONITORING MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 147 ...

Страница 148: ......

Страница 150: ......

Страница 156: ......

Страница 157: ...TILT SENSING OPTION MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 157 APPENDIX L Tilt Sensing Option ...

Страница 158: ......

Страница 162: ...TILT SENSING OPTION MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 162 ...

Страница 164: ......

Страница 168: ...HOOK HEIGHT DISRCI4100 DISPLAY OPTION MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 168 ...

Страница 169: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 169 APPENDIX N System Drawings ...

Страница 170: ......

Страница 171: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 171 ...

Страница 172: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 172 ...

Страница 173: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 173 ...

Страница 174: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 174 ...

Страница 175: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 175 ...

Страница 176: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 176 ...

Страница 177: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 177 ...

Страница 178: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 178 ...

Страница 179: ...SYSTEM DRAWINGS MAN 1111 Rev H Copyright 2015 LSI Robway Pty Ltd Page 179 ...

Страница 180: ......

Страница 182: ......