First start-up

30

5

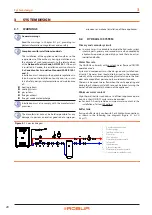

Figure 4.8

Wiring for 2 units with low voltage transformer

1

Unit 1

2

Unit 2

3

Jumper open

4

Ground pin

1

2

3

3

4

4

5

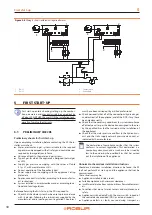

FIRST START-UP

First start-up entails checking/setting up the combus-

tion parameters and may exclusively be carried out by

a Robur AT. NEITHER the user NOR the installation tech-

nician is authorised to perform such operations, under

penalty of voiding the warranty.

5.1

PRELIMINARY CHECKS

Preliminary checks for first start-up

Upon completing installation, before contacting the AT the in-

staller must check:

▶

Water, electrical and gas systems suitable for the required

capacities and equipped with all safety and control devices

required by the regulations in force.

▶

Absence of leaks in the water and gas systems.

▶

Type of gas for which the appliance is designed (natural gas

or LPG).

▶

Supply gas pressure complying with the values of Table

5.1

p. 31, with max tolerance ±15%.

▶

Correct operation of the flue exhaust duct.

▶

Power supply mains complying with the appliance's rating

plate data.

▶

Appliance correctly installed, according to the manufactur-

er's instructions.

▶

System installed in a workmanlike manner, according to na-

tional and local regulations.

Before performing the first start-up, the AT is required to:

▶

Check that the whole system has been set up in accordance

with its design, following the instructions supplied by the

manufacturer and respecting current regulation. The project

must have been carried out by a skilled professional.

▶

Check personally that all of the connections (hydraulic, gas

and electrical) of the appliance (and of the DDC, if any) have

been made correctly.

▶

Check that the necessary conditions for system compliance

effectively exist (as per the declaration consigned to the user

by the qualified firm that has carried out the installation of

the appliance).

▶

Check that the water pressure and flow in the hydraulic cir-

cuit and the static supply network pressure are correct, as

indicated by the manufacturer.

The declaration of compliance certifies that the system

conforms to current regulations. This declaration is a

compulsory document, and as such must be issued by

law to the owner by the qualified firm that has carried

out the installation of the appliance.

Abnormal or hazardous installation situations

Should any hazardous installation situations be found, the AT

shall not perform first start-up and the appliance shall not be

commissioned.

These situations may be:

▶

Appliance installed inside a room.

▶

Failed compliance with minimum clearances.

▶

Insufficient distance from combustible or flammable materi-

als.

▶

Conditions that do not warrant access and maintenance in

safety.

▶

Appliance switched on/off with the main switch, instead of

the control device provided (DDC, or external request).

▶

Appliance defects or faults caused during transport or