4 Electrical installer

Installation, Use and Maintenance Manual – GAHP-A

29

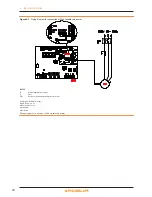

4�5 WATER CIRCULATION PUMP

4�5�1 Option (1) CONSTANT FLOW circulating pump

It must be mandatorily controlled from the S61 electronic board.

The diagram in Figure 4.6 p. 29 is for pumps < 700 W. For

pumps > 700 W it is required to add a control relay and arrange

Jumper J10 OPEN.

How to connect the CONSTANT FLOW circulating

pump

Access the Electrical Board of the appliance according

to the Procedure 4.2 p. 25

1. connect board S61, to terminals 3-4 of terminal

board (MA);

2. Jumper J10 CLOSED.

Figure 4�6 – Electrical wiring diagram

Example of pump/appliance electrical connection with 230 Vac pump (with absorbed power of < 700 W), controlled directly by the appliance.

4�5�2 Option (2) VARIABLE FLOW circulating pump

It must be mandatorily controlled from the Mod10 electronic

board (built into the S61).

How to connect the VARIABLE FLOW circulating

pump

The Wilo Stratos Para pump is already standard supplied

with the power supply cable and signal cable, both

1.5m long.

For longer distances, use respectively cable FG7

3Gx1.5mm² m and shielded cable 2x0.75 mm² suitable

for 0-10V signal.

To connect the Wilo Stratos Para pump (Figure

4.7 p. 30 J 45 or 4.8 p. 31 J 46)

1. Connect the brown wire of the pump to terminal "-"

HPMP of the Mod10 board, and the white wire of the

pump to terminal "+" HPMP of the Mod10 board.

2. Isolate the black wire and the blue one.

3.

Protect the pump's supply line with a double

pole switch with 2 A delayed fuse (Detail IP, Fig-

ure 4.7 p. 30 J 45), or connect it directly to the

terminals inside the appliance's Electrical Board (De-

tail MA, Figure 4.8 p. 31 J 46).

LEGEND

SCH

circuit board

J10

closed jumper

N.O. CONTACT

N.O voltage free contacts

MA

unit terminal block

L

phase

N

neutral

Components NOT SUPPLIED

PM

water pump <700W