1 Features and technical data

16

For each mode, (1) o (2), specific control systems and devices are

provided (Paragraph 1.5 p. 13).

1�7 CONTROLS

Control device

The appliance may only work if it is connected to a control de-

vice, selected from:

▶

(1) DDC control

▶

(2) CCP/CCI control

▶

(3) external request

1�7�1 Adjustment system (1) with DDC (GAHP unit ON/OFF)

The DDC controller is able to manage appliances, a single GAHP

unit, or even several Robur GAHP/GA/AY units in cascade, only

in ON/OFF mode (non modulating). For more details refer to the

DDC, RB100, RB200 Manuals and the Design Manual.

DDC Controller

The main functions are:

▶

adjustment and control of one (or more) Robur units of the

absorption line (GAHP, GA, AY);

▶

parameter figures display and setting;

▶

hourly programming;

▶

climate curve control;

▶

diagnostics;

▶

reset errors;

▶

possibility to interface with a BMS;

DDC functionality may be widened with auxiliary Robur devices

RB100 and RB200 (e.g. service requests, DHW production, Third

Party generator control, probe control, system valves or circulat-

ing pumps, ...).

1�7�2 Adjustment system (2) with CCP/CCI (modulating

GAHP unit)

The CCP/CCI control is able to control up to 3 GAHP units in mod-

ulating mode (therefore A/WS/GS only, excluding AR/ACF/AY),

plus any integration ON/OFF boiler. For additional details and

diagrams refer to the CCP/CCI Manual and the Design Manual.

CCP/CCI Control

See CCP/CCI device Manual.

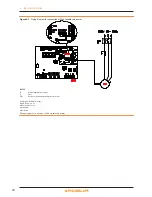

1�7�3 Adjustment system (3) with external request (GAHP

unit ON/OFF)

The appliance may also be controlled via generic enable de-

vices (e.g. thermostats, clocks, buttons, contactors...) fitted with

voltage-free NO contact. This system only provides elementary

control (on/off, with fixed set-point temperature), hence without

the important functions of systems (1) and (2). It is advisable to

limit its possible use only to simple applications and with a sin-

gle appliance.

For connection of the selected device to the appliance's

electronic board please refer to Paragraph 4.4 p. 27.

1�8 TECHNICAL CHARACTERISTICS

(see Table 1.1 p. 16).

Table 1�1 – GAHP-A HT technical data

GAHP-A HT STD

GAHP-A HT S1

HEATING MODE

Seasonal space heating energy ef-

ficiency class (ErP)

medium-temperature application (55 °C)

A+

low-temperature application (35 °C)

A+

OPERATING POINT A7W50

G.U.E. gas usage efficiency

%

152 (1)

Thermal power

kW

38,3 (1)

OPERATING POINT A7W35

G.U.E. gas usage efficiency

%

164 (1)

Thermal power

kW

41,3 (1)

OPERATING POINT A7W65

G.U.E. gas usage efficiency

%

124 (1)

Thermal power

kW

31,1 (1)

OPERATING POINT A-7W50

G.U.E. gas usage efficiency

%

127 (1)

Thermal power

kW

32,0 (1)

Heating capacity

Nominal (1013 mbar - 15°C)

kW

25,7

true peak

kW

25,2

Hot water delivery temperature

maximum for heating

°C

65

maximum for DHW

°C

70

Hot water inlet temperature

maximum heating

°C

55

maximum for DHW

°C

60

minimum temperature in continuous

operation

°C

30 (11)

Thermal differential

nominal

°C

10

Hot water flow rate

nominal

l/h

3000

maximum

l/h

4000

minimum

l/h

1400

Hot water pressure loss

nominal water pressure (A7W50)

bar

0,43 (2)

Ambient air temperature (dry bulb)

maximum

°C

40

minimum

°C

-15 (7)

ELECTRICAL SPECIFICATIONS

Power supply

Voltage

V

230

TYPE

SINGLE PHASE

Frequency

50 Hz supply

50