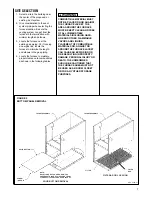

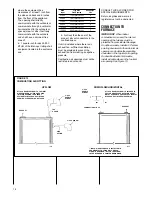

CEMENTING JOINTS

Properly seal all joints in the PVC

vent using the following materials and

procedures.

PVC CLEANER-PRIMER AND

PVC MEDIUM-BODY SOLVENT

CEMENT

IMPORTANT: After cutting pipe,

remove all ragged edges and burrs.

This is important to prevent reduction

in pressure drop throughout the

system.

1. Cut pipe end square. Chamfer

edge of pipe. Clean fitting socket

and pipe joint area of all dirt,

grease and moisture.

2. After checking pipe and socket

for proper fit, wipe socket and

pipe with cleaner-primer. Apply

a liberal coat of primer to inside

surface of socket and outside of

pipe. Read instructions included

with the primer for proper

application.

3. Apply a thin coat of cement

evenly in the socket. Quickly

apply a heavy coat of cement to

the pipe end and insert pipe into

fitting with a slight twisting

movement until it bottoms out.

NOTE: Cement must be fluid; if

not, recoat.

4. Hold the pipe in the fitting for 30

seconds to prevent the tapered

socket from pushing the pipe out

of the fitting.

5. Wipe all excess cement from the

joint with a rag. Allow 15 minutes

before handling. Cure time varies

according to fit, temperature and

humidity.

NOTE: Stir the solvent cement

frequently while using. Use a natural

bristle brush or the dauber supplied

with the can. The proper brush size is

one inch.

IMPORTANT: For Proper Installation

DO NOT use solvent cement that

has become curdled, lumpy or

thickened.

DO NOT thin. Observe shelf

precautions printed on containers.

For application below 32°F, use only

low-temperature-type solvent

cement.

13

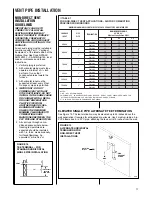

4. Follow the lighting instructions.

Place the appliance being

inspected into operation. Adjust

the thermostat so the appliance

will operate continuously.

5. Test for spillage at the draft hood

relief opening after 5 minutes of

main burner operation. Use the

flame of a match or candle, or

smoke from a cigarette, cigar

or pipe.

6. After it has been determined that

each appliance that remains

connected to the common

venting system properly vents

(when tested as outlined above),

return doors, windows, exhaust

fans, fireplace dampers and any

other gas-burning appliance to

their previous conditions of use.

7. If improper venting is observed

during any of the above tests, the

common venting system must be

resized. Refer to latest edition of

the National Fuel Gas Code

ANSI Z223.1, 1992 or the AGA-

GAMA venting tables for

Category I furnaces.

When the furnace is installed in the

same space with other gas

appliances such as a water heater, be

sure there is an adequate supply of

combustion and ventilation air for the

other appliances. Do not delete or

reduce the combustion air supply

required by the other gas appliances

in this space. See Z223.1, National

Fuel Gas Code (NFPA54) or

CAN/CGA-B149.1 and .2 for deter-

mining the combustion air require-

ments for gas appliances. An

unconfined space must have at least

50 cubic feet (volume) for each

1,000 BTUH of the total input of all

appliances in the space. If the open

space containing the appliances is in

a building with tight construction

(contemporary construction), outside

air may still be required for the

appliances to burn and vent properly.

Outside air openings should be sized

the same as for a confined space.

JOINING PIPE AND

FITTINGS

PVC SOLVENT CEMENTS AND

PRIMERS ARE HIGHLY FLAM-

MABLE. PROVIDE ADEQUATE

VENTILATION AND DO NOT

ASSEMBLE NEAR HEAT SOURCE

OR AN OPEN FLAME. DO NOT

SMOKE. AVOID SKIN OR EYE

CONTACT. OBSERVE ALL

CAUTIONS AND WARNINGS

PRINTED ON MATERIAL CON-

TAINERS. FAILURE TO FOLLOW

THESE GUIDELINES MAY RESULT

IN FIRE, EXPLOSION OR

ASPHYXIATION CAUSING

PERSONAL INJURY OR DEATH.

All pipe, fittings, solvent cement,

primers and procedures must

conform to American National

Standard Institute and American

Society for Testing and Materials

(ANSI/ASTM) standards in the U.S.

Pipe and Fittings - ASTM-D1785,

D2466, D2665, D2231, D2661 and

F628.

PVC Primer and Solvent Cement -

ASTM-D2564

ABS Pipe and Fittings - Use ABS

Primer and Solvent Cement D2235

Procedure for Cementing Joints -

ASTM-D2855

IMPORTANT: The plastic combustion

air and venting components are of

PVC. If using ABS piping, ensure that

the solvent cement is compatible for

joining PVC to ABS components or

use a mechanical connection that can

withstand the vent temperatures and

are corrosion resistant.

!

WARNING

Содержание RGRA SERIES

Страница 38: ...38 FIGURE 45 HONEYWELL NO S9201E2001 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I400...

Страница 39: ...39 FIGURE 46 HONEYWELL NO S9201E2001 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I401...

Страница 40: ...40 FIGURE 47 UTEC NO 1012 920 1028 927 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I398...

Страница 41: ...41 FIGURE 48 UTEC NO 1012 920 1028 927 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I398...

Страница 42: ...42 FIGURE 49 JOHNSON CONTROLS G961DAJ 2401 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I399...

Страница 43: ...43 FIGURE 50 JOHNSON CONTROLS G961DAJ 2401 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I399...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64 Rheem Manufacturing Company Air Conditioning Division Fort Smith Arkansas CM 1197...