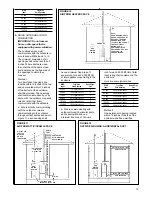

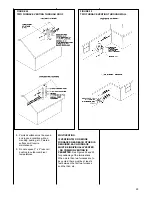

FIGURE 29

DOWNFLOW CONDENSATE DRAIN

CONDENSATE DRAIN/NEUTRALIZER

27

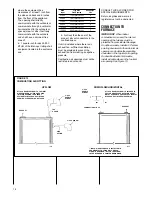

FIGURE 28

UPFLOW CONDENSATE DRAIN

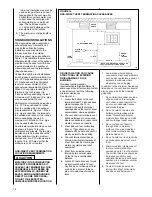

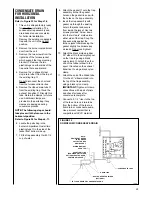

GENERAL INFORMATION

DO NOT RUN DRAIN OUTDOORS.

FREEZING OF CONDENSATE CAN

CAUSE PROPERTY DAMAGE.

IMPORTANT: Do not connect into a

common drain line with an air con-

ditioner evaporator coil drain located

below the furnace. A blocked or

restricted drain line can result in over-

flow of the coil pan and negate the

furnace blocked drain shutoff control.

FILL TRAP ASSEMBLY WITH

WATER BEFORE OPERATING THE

FURNACE.

This can be done by

removing the drain hose

from the trap and pouring about a

cup of water into the vent trap. Water

will flow into the house drain when the

trap is full.

If local codes require, install a

condensate neutralizer cartridge in

the drain line. Install cartridge in

horizontal position only. Also install

an overflow line if routing to a floor

drain. See Figures 28 and 29.

If no floor drain is available, install a

condensate pump that is resistant to

acidic water. Pumps are available

from your local distributor. If pump

used is not resistant to acidic water, a

condensate neutralizer must be used

ahead of the pump. The condensate

pump must have an auxiliary safety

switch to prevent operation of the

furnace and resulting overflow of

condensate in the event of pump

failure. The safety switch must be

wired through the “R” circuit only (low

voltage) to provide operation in either

heating or cooling modes.

UPFLOW MODELS

The condensate drain trap is located

in the blower compartment on the left-

hand side of the jacket. A short piece

of

1

/

2

-in. PVC pipe and a

1

/

2

-in. tee are

provided. Connect the

1

/

2

-in. pipe to

the elbow on the trap and the tee to

this pipe so that the open end is

upward. Connect at least a 5

(

riser to

the top of the tee and run a drain tube

from the bottom of the tee to a floor

drain or condensate pump.

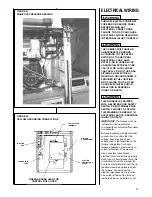

IMPORTANT:

If installing the unit

over a finished ceiling or living area,

be certain to install an auxiliary

condensate drain pan under the

entire unit extending out under the

condensate tee. With a 5 inch riser

installed above the tee, a blocked

drain will result in overflow from the

riser.

To cause the furnace to shut down

when a blocked drain is present,

install a riser which is a minimum of

10

13

⁄

16

(

. If the furnace is installed in an

attic, crawlspace or other area where

freezing temperatures may occur, the

furnace drain can freeze while shut

off for long periods of time.

Use a solvent cement that is

compatible with PVC material. Cut the

drain hoses to the appropriate length

and connect to the trap with hose

clamps. Tighten the clamps with

pliers and check for leaks after

attaching.

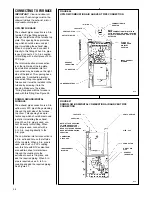

DOWNFLOW MODELS

The condensate trap is located on the

right side of the cabinet in the burner

compartment. A short piece of

1

/

2

-in.

PVC pipe and a

1

/

2

-in. tee are

provided. Connect the

1

/

2

-in. pipe to

the elbow on the trap and the tee to

this pipe so that the open end is

upward. Connect a 5

1

⁄

2

-in. riser to the

top of the tee and run a drain tube

from the bottom of the tee to a floor

drain or condensate pump. Use a

solvent cement that is compatible with

PVC material.

!

CAUTION

NEUTRALIZER CARTRIDGE

(OPTIONAL)

TO FLOOR DRAIN OR CONDENSATE PUMP

NOTE:

DRAIN VENT NEEDS

TO BE ABOVE

COLLECTOR BOX

DRAIN SPOUT.

MINIMUM HEIGHT

OPEN TOP

CONDENSATE TRAP

DRAIN LINE

I408

OVERFLOW LINE

(REQUIRED ONLY WHEN

OPTIONAL NEUTRALIZER

CARTRIDGE IS USED.)

I408

MINIMUM HEIGHT

OPEN TOP

DRAIN LINE

CONDENSATE TRAP

TO FLOOR DRAIN OR CONDENSATE PUMP

NEUTRALIZER CARTRIDGE

(OPTIONAL)

OVERFLOW LINE

(REQUIRED ONLY WHEN

OPTIONAL NEUTRALIZER

CARTRIDGE IS USED.)

5

(

Содержание RGRA SERIES

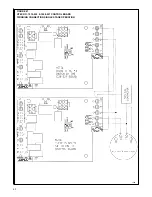

Страница 38: ...38 FIGURE 45 HONEYWELL NO S9201E2001 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I400...

Страница 39: ...39 FIGURE 46 HONEYWELL NO S9201E2001 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I401...

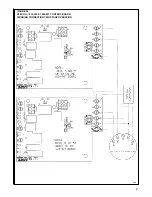

Страница 40: ...40 FIGURE 47 UTEC NO 1012 920 1028 927 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I398...

Страница 41: ...41 FIGURE 48 UTEC NO 1012 920 1028 927 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I398...

Страница 42: ...42 FIGURE 49 JOHNSON CONTROLS G961DAJ 2401 CONTROL BOARD TWINNING CONNECTION SINGLE STAGE OPERATION I399...

Страница 43: ...43 FIGURE 50 JOHNSON CONTROLS G961DAJ 2401 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION I399...

Страница 62: ...62...

Страница 63: ...63...

Страница 64: ...64 Rheem Manufacturing Company Air Conditioning Division Fort Smith Arkansas CM 1197...